twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

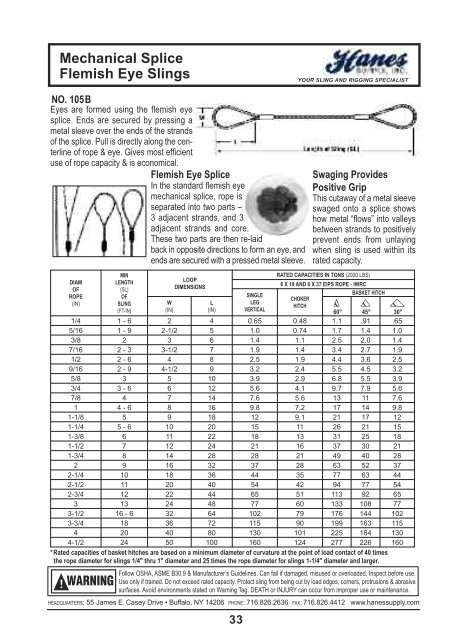

Mechanical spliceflemish eye <strong>sl<strong>in</strong>gs</strong>YOUR SLING AND RIGGING SPECIALISTNO. 105BEyes are formed us<strong>in</strong>g the flemish eyesplice. Ends are secured by press<strong>in</strong>g ametal sleeve over the ends of the strandsof the splice. Pull is directly along the centerl<strong>in</strong>eof rope & eye. Gives most efficientuse of rope capacity & is economical.Flemish Eye SpliceIn the standard flemish eyemechanical splice, rope isseparated <strong>in</strong>to two parts –3 adjacent strands, and 3adjacent strands and core.These two parts are then re-laidback <strong>in</strong> opposite directions to form an eye, andends are secured with a pressed metal sleeve.MINRATED CAPACITIES IN TONS (2000 LBS)DIAMLENGTHLOOPOF(SL)DIMENSIONS6 X 19 AND 6 X 37 EIPS ROPE - IWRCROPEOFSINGLEBASKET HITCHCHOKER(IN)SLINGWLLEGHITCH(FT-IN)(IN)(IN) VERTICAL60° 45° 30°1/4 1 - 6 2 4 0.65 0.48 1.1 .91 .655/16 1 - 9 2-1/2 5 1.0 0.74 1.7 1.4 1.03/8 2 3 6 1.4 1.1 2.5 2.0 1.47/16 2 - 3 3-1/2 7 1.9 1.4 3.4 2.7 1.91/2 2 - 6 4 8 2.5 1.9 4.4 3.6 2.59/16 2 - 9 4-1/2 9 3.2 2.4 5.5 4.5 3.25/8 3 5 10 3.9 2.9 6.8 5.5 3.93/4 3 - 6 6 12 5.6 4.1 9.7 7.9 5.67/8 4 7 14 7.6 5.6 13 11 7.61 4 - 6 8 16 9.8 7.2 17 14 9.81-1/8 5 9 18 12 9.1 21 17 121-1/4 5 - 6 10 20 15 11 26 21 151-3/8 6 11 22 18 13 31 25 181-1/2 7 12 24 21 16 37 30 211-3/4 8 14 28 28 21 49 40 282 9 16 32 37 28 63 52 372-1/4 10 18 36 44 35 77 63 442-1/2 11 20 40 54 42 94 77 542-3/4 12 22 44 65 51 113 92 653 13 24 48 77 60 133 108 773-1/2 16 - 6 32 64 102 79 176 144 1023-3/4 18 36 72 115 90 199 163 1154 20 40 80 130 101 225 184 1304-1/2 24 50 100 160 124 277 226 160*Rated capacities of basket hitches are based on a m<strong>in</strong>imum diameter of curvature at the po<strong>in</strong>t of load contact of 40 timesthe rope diameter for <strong>sl<strong>in</strong>gs</strong> 1/4" thru 1" diameter and 25 times the rope diameter for <strong>sl<strong>in</strong>gs</strong> 1-1/4" diameter and larger.HEADQUARTERS: 55 James E. Casey Drive • Buffalo, NY 14206 PHONE: 716.826.2636 FAX: 716.826.4412 www.hanessupply.com33Swag<strong>in</strong>g ProvidesPositive GripThis cutaway of a metal sleeveswaged onto a splice showshow metal “flows” <strong>in</strong>to valleysbetween strands to positivelyprevent ends from unlay<strong>in</strong>gwhen sl<strong>in</strong>g is used with<strong>in</strong> itsrated capacity.Follow OSHA, ASME B30.9 & Manufacturer’s Guidel<strong>in</strong>es. Can fail if damaged, misused or overloaded. Inspect before use.Use only if tra<strong>in</strong>ed. Do not exceed rated capacity. Protect sl<strong>in</strong>g from be<strong>in</strong>g cut by load edges, corners, protrusions & abrasive! WARNINGsurfaces. Avoid environments stated on Warn<strong>in</strong>g Tag. DEATH or INJURY can occur from improper use or ma<strong>in</strong>tenance.