twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

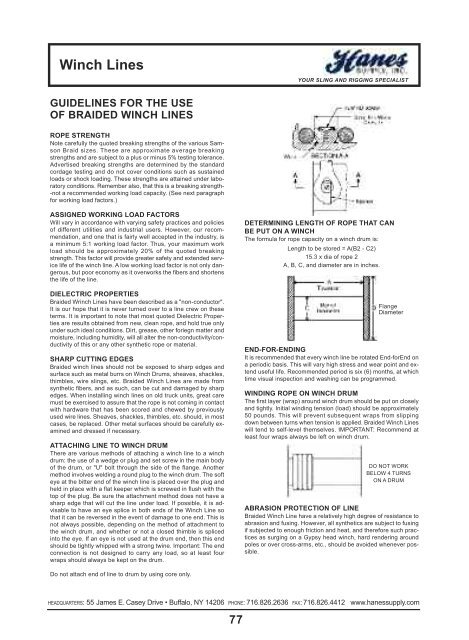

W<strong>in</strong>ch l<strong>in</strong>esYOUR SLING AND RIGGING SPECIALISTGUIDelInes foR tHe Useof bRaIDeD W<strong>Inc</strong>H lInesRoPe stRenGtHNote carefully the quoted break<strong>in</strong>g strengths of the various SamsonBraid sizes. These are approximate average break<strong>in</strong>gstrengths and are subject to a plus or m<strong>in</strong>us 5% test<strong>in</strong>g tolerance.Advertised break<strong>in</strong>g strengths are determ<strong>in</strong>ed by the standardcordage test<strong>in</strong>g and do not cover conditions such as susta<strong>in</strong>edloads or shock load<strong>in</strong>g. These strengths are atta<strong>in</strong>ed under laboratoryconditions. Remember also, that this is a break<strong>in</strong>g strength--not a recommended work<strong>in</strong>g load capacity. (See next paragraphfor work<strong>in</strong>g load factors.)assIGneD WoRkInG loaD factoRsWill vary <strong>in</strong> accordance with vary<strong>in</strong>g safety practices and policiesof different utilities and <strong>in</strong>dustrial users. However, our recommendation,and one that is fairly well accepted <strong>in</strong> the <strong>in</strong>dustry, isa m<strong>in</strong>imum 5:1 work<strong>in</strong>g load factor. Thus, your maximum workload should be approximately 20% of the quoted break<strong>in</strong>gstrength. This factor will provide greater safety and extended servicelife of the w<strong>in</strong>ch l<strong>in</strong>e. A low work<strong>in</strong>g load factor is not only dangerous,but poor economy as it overworks the fibers and shortensthe life of the l<strong>in</strong>e.DIelectRIc PRoPeRtIesBraided Wr<strong>in</strong>ch L<strong>in</strong>es have been described as a "non-conductor".It is our hope that it is never turned over to a l<strong>in</strong>e crew on theseterms. It is important to note that most quoted Dielectric Propertiesare results obta<strong>in</strong>ed from new, clean rope, and hold true onlyunder such ideal conditions. Dirt, grease, other foriegn matter andmoisture, <strong>in</strong>clud<strong>in</strong>g humidity, will all alter the non-conductivity/conductivityof this or any other synthetic rope or material.sHaRP cUttInG eDGesBraided w<strong>in</strong>ch l<strong>in</strong>es should not be exposed to sharp edges andsurface such as metal burrs on W<strong>in</strong>ch Drums, sheaves, shackles,thimbles, wire <strong>sl<strong>in</strong>gs</strong>, etc. Braided W<strong>in</strong>ch L<strong>in</strong>es are made fromsynthetic fibers, and as such, can be cut and damaged by sharpedges. When <strong>in</strong>stall<strong>in</strong>g w<strong>in</strong>ch l<strong>in</strong>es on old truck units, great caremust be exercised to assure that the rope is not com<strong>in</strong>g <strong>in</strong> contactwith hardware that has been scored and chewed by previouslyused wire l<strong>in</strong>es. Sheaves, shackles, thimbles, etc. should, <strong>in</strong> mostcases, be replaced. Other metal surfaces should be carefully exam<strong>in</strong>edand dressed if necessary.attacHInG lIne to W<strong>Inc</strong>H DRUMThere are various methods of attach<strong>in</strong>g a w<strong>in</strong>ch l<strong>in</strong>e to a w<strong>in</strong>chdrum: the use of a wedge or plug and set screw <strong>in</strong> the ma<strong>in</strong> bodyof the drum, or "U" bolt through the side of the flange. Anothermethod <strong>in</strong>volves weld<strong>in</strong>g a round plug to the w<strong>in</strong>ch drum. The softeye at the bitter end of the w<strong>in</strong>ch l<strong>in</strong>e is placed over the plug andheld <strong>in</strong> place with a flat keeper which is screwed <strong>in</strong> flush with thetop of the plug. Be sure the attachment method does not have asharp edge that will cut the l<strong>in</strong>e under load. If possible, it is advisableto have an eye splice <strong>in</strong> both ends of the W<strong>in</strong>ch L<strong>in</strong>e sothat it can be reversed <strong>in</strong> the event of damage to one end. This isnot always possible, depend<strong>in</strong>g on the method of attachment tothe w<strong>in</strong>ch drum, and whether or not a closed thimble is spliced<strong>in</strong>to the eye. If an eye is not used at the drum end, then this endshould be tightly whipped with a strong <strong>tw<strong>in</strong></strong>e. Important: The endconnection is not designed to carry any load, so at least fourwraps should always be kept on the drum.DeteRMInInG lenGtH of RoPe tHat canbe PUt on a W<strong>Inc</strong>HThe formula for rope capacity on a w<strong>in</strong>ch drum is:Length to be stored = A(B2 - C2)15.3 x dia of rope 2A, B, C, and diameter are <strong>in</strong> <strong>in</strong>ches.FlangeDiameterenD-foR-enDInGIt is recommended that every w<strong>in</strong>ch l<strong>in</strong>e be rotated End-forEnd ona periodic basis. This will vary high stress and wear po<strong>in</strong>t and extenduseful life. Recommended period is six (6) months, at whichtime visual <strong>in</strong>spection and wash<strong>in</strong>g can be programmed.WInDInG RoPe on W<strong>Inc</strong>H DRUMThe first layer (wrap) around w<strong>in</strong>ch drum should be put on closelyand tightly. Initial w<strong>in</strong>d<strong>in</strong>g tension (load) should be approximately50 pounds. This will prevent subsequent wraps from slipp<strong>in</strong>gdown between turns when tension is applied. Braided W<strong>in</strong>ch L<strong>in</strong>eswill tend to self-level themselves. IMPORTANT: Recommend atleast four wraps always be left on w<strong>in</strong>ch drum.DO NOT WORKBELOW 4 TURNSON A DRUMabRasIon PRotectIon of lIneBraided W<strong>in</strong>ch L<strong>in</strong>e have a relatively high degree of resistance toabrasion and fus<strong>in</strong>g. However, all synthetics are subject to fus<strong>in</strong>gif subjected to enough friction and heat, and therefore such practicesas surg<strong>in</strong>g on a Gypsy head w<strong>in</strong>ch, hard render<strong>in</strong>g aroundpoles or over cross-arms, etc., should be avoided whenever possible.Do not attach end of l<strong>in</strong>e to drum by us<strong>in</strong>g core only.HEADQUARTERS: 55 James E. Casey Drive • Buffalo, NY 14206 PHONE: 716.826.2636 FAX: 716.826.4412 www.hanessupply.com77