twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

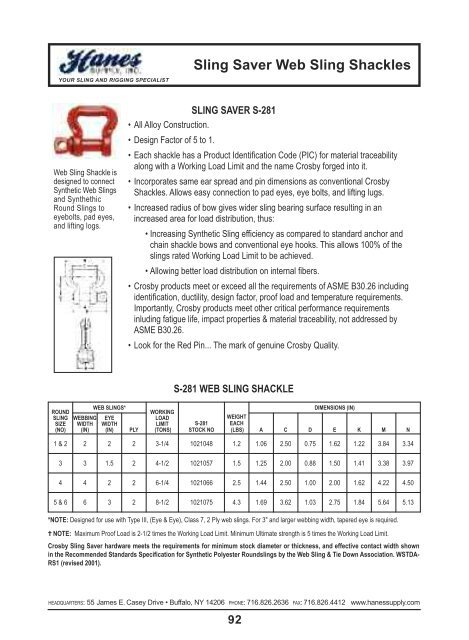

YOUR SLING AND RIGGING SPECIALISTsl<strong>in</strong>g saver Web sl<strong>in</strong>g shacklesWeb Sl<strong>in</strong>g Shackle isdesigned to connectSynthetic Web Sl<strong>in</strong>gsand SynthethicRound Sl<strong>in</strong>gs toeyebolts, pad eyes,and lift<strong>in</strong>g logs.SLING SAVER S-281• All Alloy Construction.• Design Factor of 5 to 1.• Each shackle has a Product Identification Code (PIC) for material traceabilityalong with a Work<strong>in</strong>g Load Limit and the name Crosby forged <strong>in</strong>to it.• <strong>Inc</strong>orporates same ear spread and p<strong>in</strong> dimensions as conventional CrosbyShackles. Allows easy connection to pad eyes, eye bolts, and lift<strong>in</strong>g lugs.• <strong>Inc</strong>reased radius of bow gives wider sl<strong>in</strong>g bear<strong>in</strong>g surface result<strong>in</strong>g <strong>in</strong> an<strong>in</strong>creased area for load distribution, thus:• <strong>Inc</strong>reas<strong>in</strong>g Synthetic Sl<strong>in</strong>g efficiency as compared to standard anchor andcha<strong>in</strong> shackle bows and conventional eye hooks. This allows 100% of the<strong>sl<strong>in</strong>gs</strong> rated Work<strong>in</strong>g Load Limit to be achieved.• Allow<strong>in</strong>g better load distribution on <strong>in</strong>ternal fibers.• Crosby products meet or exceed all the requirements of ASME B30.26 <strong>in</strong>clud<strong>in</strong>gidentification, ductility, design factor, proof load and temperature requirements.Importantly, Crosby products meet other critical performance requirements<strong>in</strong>lud<strong>in</strong>g fatigue life, impact properties & material traceability, not addressed byASME B30.26.• Look for the Red P<strong>in</strong>... The mark of genu<strong>in</strong>e Crosby Quality.ROUNDSLINGSIZE(NO)S-281 WEB SLING SHACKLEWEB SLINGS*WORKINGDIMENSIONS (IN)WEBBINGWIDTH(IN)EYEWIDTH(IN) PLYLOADLIMIT(TONS)S-281STOCK NOWEIGHTEACH(LBS) A C D E K M N1 & 2 2 2 2 3-1/4 1021048 1.2 1.06 2.50 0.75 1.62 1.22 3.84 3.343 3 1.5 2 4-1/2 1021057 1.5 1.25 2.00 0.88 1.50 1.41 3.38 3.974 4 2 2 6-1/4 1021066 2.5 1.44 2.50 1.00 2.00 1.62 4.22 4.505 & 6 6 3 2 8-1/2 1021075 4.3 1.69 3.62 1.03 2.75 1.84 5.64 5.13*NOTE: Designed for use with Type III, (Eye & Eye), Class 7, 2 Ply web <strong>sl<strong>in</strong>gs</strong>. For 3" and larger webb<strong>in</strong>g width, tapered eye is required.✝ NOTE: Maximum Proof Load is 2-1/2 times the Work<strong>in</strong>g Load Limit. M<strong>in</strong>imum Ultimate strength is 5 times the Work<strong>in</strong>g Load Limit.Crosby Sl<strong>in</strong>g Saver hardware meets the requirements for m<strong>in</strong>imum stock diameter or thickness, and effective contact width shown<strong>in</strong> the Recommended Standards Specification for Synthetic Polyester Round<strong>sl<strong>in</strong>gs</strong> by the Web Sl<strong>in</strong>g & Tie Down Association. WSTDA-RS1 (revised 2001).HEADQUARTERS: 55 James E. Casey Drive • Buffalo, NY 14206 PHONE: 716.826.2636 FAX: 716.826.4412 www.hanessupply.com92