twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

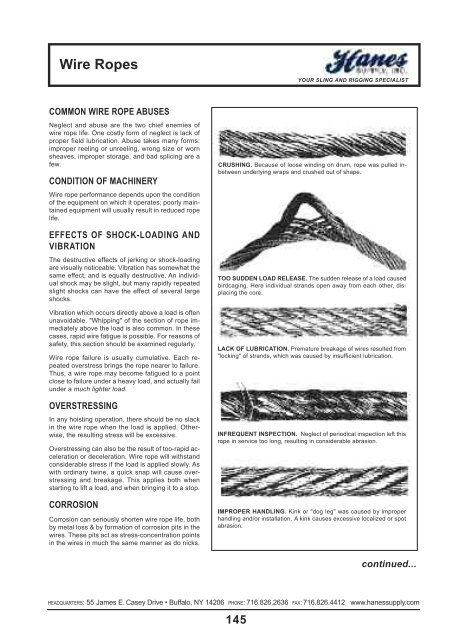

Wire RopesYOUR SLING AND RIGGING SPECIALISTCOMMON WIRE ROPE ABUSESNeglect and abuse are the two chief enemies ofwire rope life. One costly form of neglect is lack ofproper field lubrication. Abuse takes many forms:improper reel<strong>in</strong>g or unreel<strong>in</strong>g, wrong size or wornsheaves, improper storage, and bad splic<strong>in</strong>g are afew.CONDITION OF MACHINERYWire rope performance depends upon the conditionof the equipment on which it operates; poorly ma<strong>in</strong>ta<strong>in</strong>edequipment will usually result <strong>in</strong> reduced ropelife.EFFECTS OF SHOCK-LOADING ANDVIBRATIONThe destructive effects of jerk<strong>in</strong>g or shock-load<strong>in</strong>gare visually noticeable. Vibration has somewhat thesame effect, and is equally destructive. An <strong>in</strong>dividualshock may be slight, but many rapidly repeatedslight shocks can have the effect of several largeshocks.Vibration which occurs directly above a load is oftenunavoidable. "Whipp<strong>in</strong>g" of the section of rope immediatelyabove the load is also common. In thesecases, rapid wire fatigue is possible. For reasons ofsafety, this section should be exam<strong>in</strong>ed regularly.Wire rope failure is usually cumulative. Each repeatedoverstress br<strong>in</strong>gs the rope nearer to failure.Thus, a wire rope may become fatigued to a po<strong>in</strong>tclose to failure under a heavy load, and actually failunder a much lighter load.OVERSTRESSINGIn any hoist<strong>in</strong>g operation, there should be no slack<strong>in</strong> the wire rope when the load is applied. Otherwise,the result<strong>in</strong>g stress will be excessive.Overstress<strong>in</strong>g can also be the result of too-rapid accelerationor deceleration. Wire rope will withstandconsiderable stress if the load is applied slowly. Aswith ord<strong>in</strong>ary <strong>tw<strong>in</strong></strong>e, a quick snap will cause overstress<strong>in</strong>gand breakage. This applies both whenstart<strong>in</strong>g to lift a load, and when br<strong>in</strong>g<strong>in</strong>g it to a stop.CORROSIONCorrosion can seriously shorten wire rope life, bothby metal loss & by formation of corrosion pits <strong>in</strong> thewires. These pits act as stress-concentration po<strong>in</strong>ts<strong>in</strong> the wires <strong>in</strong> much the same manner as do nicks.cRUsHInG. Because of loose w<strong>in</strong>d<strong>in</strong>g on drum, rope was pulled <strong>in</strong>betweenunderly<strong>in</strong>g wraps and crushed out of shape.too sUDDen loaD Release. The sudden release of a load causedbirdcag<strong>in</strong>g. Here <strong>in</strong>dividual strands open away from each other, displac<strong>in</strong>gthe core.lack of lUbRIcatIon. Premature breakage of wires resulted from"lock<strong>in</strong>g" of strands, which was caused by <strong>in</strong>sufficient lubrication.InfReQUent InsPectIon. Neglect of periodical <strong>in</strong>spection left thisrope <strong>in</strong> service too long, result<strong>in</strong>g <strong>in</strong> considerable abrasion.IMPRoPeR HanDlInG. K<strong>in</strong>k or "dog leg" was caused by improperhandl<strong>in</strong>g and/or <strong>in</strong>stallation. A k<strong>in</strong>k causes excessive localized or spotabrasion.cont<strong>in</strong>ued...HEADQUARTERS: 55 James E. Casey Drive • Buffalo, NY 14206 PHONE: 716.826.2636 FAX: 716.826.4412 www.hanessupply.com145