twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

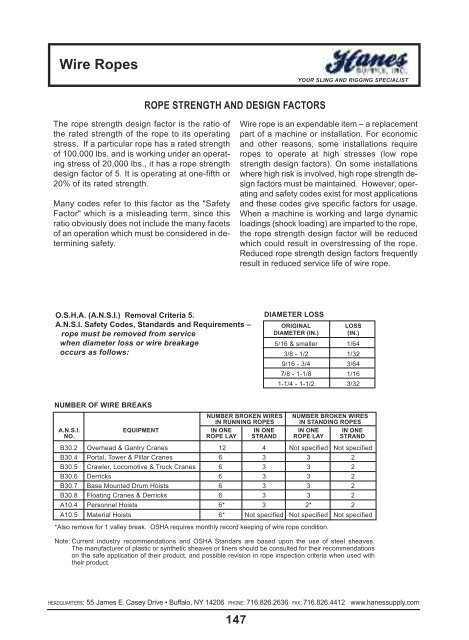

Wire RopesYOUR SLING AND RIGGING SPECIALISTROPE STRENGTH AND DESIGN FACTORSThe rope strength design factor is the ratio ofthe rated strength of the rope to its operat<strong>in</strong>gstress. If a particular rope has a rated strengthof 100,000 lbs. and is work<strong>in</strong>g under an operat<strong>in</strong>gstress of 20,000 lbs., it has a rope strengthdesign factor of 5. It is operat<strong>in</strong>g at one-fifth or20% of its rated strength.Many codes refer to this factor as the "SafetyFactor" which is a mislead<strong>in</strong>g term, s<strong>in</strong>ce thisratio obviously does not <strong>in</strong>clude the many facetsof an operation which must be considered <strong>in</strong> determ<strong>in</strong><strong>in</strong>gsafety.Wire rope is an expendable item – a replacementpart of a mach<strong>in</strong>e or <strong>in</strong>stallation. For economicand other reasons, some <strong>in</strong>stallations requireropes to operate at high stresses (low ropestrength design factors). On some <strong>in</strong>stallationswhere high risk is <strong>in</strong>volved, high rope strength designfactors must be ma<strong>in</strong>ta<strong>in</strong>ed. However, operat<strong>in</strong>gand safety codes exist for most applicationsand these codes give specific factors for usage.When a mach<strong>in</strong>e is work<strong>in</strong>g and large dynamicload<strong>in</strong>gs (shock load<strong>in</strong>g) are imparted to the rope,the rope strength design factor will be reducedwhich could result <strong>in</strong> overstress<strong>in</strong>g of the rope.Reduced rope strength design factors frequentlyresult <strong>in</strong> reduced service life of wire rope.o.s.H.a. (a.n.s.I.) Removal criteria 5.a.n.s.I. safety codes, standards and Requirements –rope must be removed from servicewhen diameter loss or wire breakageoccurs as follows:DIaMeteR lossoRIGInallossDIaMeteR (In.) (In.)5/16 & smaller 1/643/8 - 1/2 1/329/16 - 3/4 3/647/8 - 1-1/8 1/161-1/4 - 1-1/2 3/32nUMbeR of WIRe bReaksnUMbeR bRoken WIRes nUMbeR bRoken WIResIn RUnnInG RoPes In stanDInG RoPesa.n.s.I. eQUIPMent In one In one In one In oneno. RoPe laY stRanD RoPe laY stRanDB30.2 Overhead & Gantry Cranes 12 4 Not specified Not specifiedB30.4 Portal, Tower & Pillar Cranes 6 3 3 2B30.5 Crawler, Locomotive & Truck Cranes 6 3 3 2B30.6 Derricks 6 3 3 2B30.7 Base Mounted Drum Hoists 6 3 3 2B30.8 Float<strong>in</strong>g Cranes & Derricks 6 3 3 2A10.4 Personnel Hoists 6* 3 2* 2A10.5 Material Hoists 6* Not specified Not specified Not specified*Also remove for 1 valley break. OSHA requires monthly record keep<strong>in</strong>g of wire rope condition.Note: Current <strong>in</strong>dustry recommendations and OSHA Standars are based upon the use of steel sheaves.The manufacturer of plastic or synthetic sheaves or l<strong>in</strong>ers should be consulted for their recommendationson the safe application of their product, and possible revision <strong>in</strong> rope <strong>in</strong>spection criteria when used withtheir product.HEADQUARTERS: 55 James E. Casey Drive • Buffalo, NY 14206 PHONE: 716.826.2636 FAX: 716.826.4412 www.hanessupply.com147