twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

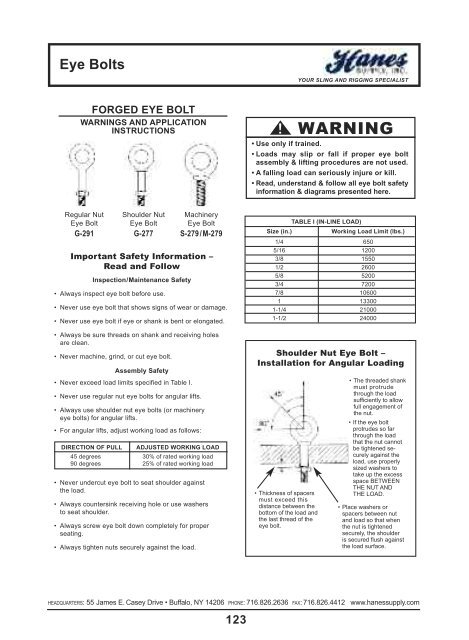

eye boltsYOUR SLING AND RIGGING SPECIALISTfoRGeD eYe boltWaRnInGs anD aPPlIcatIonInstRUctIons!WARNING• Use only if tra<strong>in</strong>ed.• loads may slip or fall if proper eye boltassembly & lift<strong>in</strong>g procedures are not used.• a fall<strong>in</strong>g load can seriously <strong>in</strong>jure or kill.• Read, understand & follow all eye bolt safety<strong>in</strong>formation & diagrams presented here.Regular NutEye BoltG-291Shoulder NutEye BoltG-277Mach<strong>in</strong>eryEye BoltS-279 / M-279Important Safety Information –Read and FollowInspection/Ma<strong>in</strong>tenance safety• Always <strong>in</strong>spect eye bolt before use.• Never use eye bolt that shows signs of wear or damage.• Never use eye bolt if eye or shank is bent or elongated.• Always be sure threads on shank and receiv<strong>in</strong>g holesare clean.• Never mach<strong>in</strong>e, gr<strong>in</strong>d, or cut eye bolt.assembly safety• Never exceed load limits specified <strong>in</strong> Table I.• Never use regular nut eye bolts for angular lifts.• Always use shoulder nut eye bolts (or mach<strong>in</strong>eryeye bolts) for angular lifts.• For angular lifts, adjust work<strong>in</strong>g load as follows:DIRectIon of PUll aDJUsteD WoRkInG loaD45 degrees 30% of rated work<strong>in</strong>g load90 degrees 25% of rated work<strong>in</strong>g load• Never undercut eye bolt to seat shoulder aga<strong>in</strong>stthe load.• Always counters<strong>in</strong>k receiv<strong>in</strong>g hole or use washersto seat shoulder.• Always screw eye bolt down completely for properseat<strong>in</strong>g.• Always tighten nuts securely aga<strong>in</strong>st the load.table I (In-lIne loaD)size (<strong>in</strong>.)Work<strong>in</strong>g load limit (lbs.)1/4 6505/16 12003/8 15501/2 26005/8 52003/4 72007/8 106001 133001-1/4 210001-1/2 24000Shoulder Nut Eye Bolt –Installation for Angular Load<strong>in</strong>g• Thickness of spacersmust exceed thisdistance between thebottom of the load andthe last thread of theeye bolt.• The threaded shankmust protrudethrough the loadsufficiently to allowfull engagement ofthe nut.• If the eye boltprotrudes so farthrough the loadthat the nut cannotbe tightened securelyaga<strong>in</strong>st theload, use properlysized washers totake up the excessspace BETWEENTHE NUT ANDTHE LOAD.• Place washers orspacers between nutand load so that whenthe nut is tightenedsecurely, the shoulderis secured flush aga<strong>in</strong>stthe load surface.HEADQUARTERS: 55 James E. Casey Drive • Buffalo, NY 14206 PHONE: 716.826.2636 FAX: 716.826.4412 www.hanessupply.com123