twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

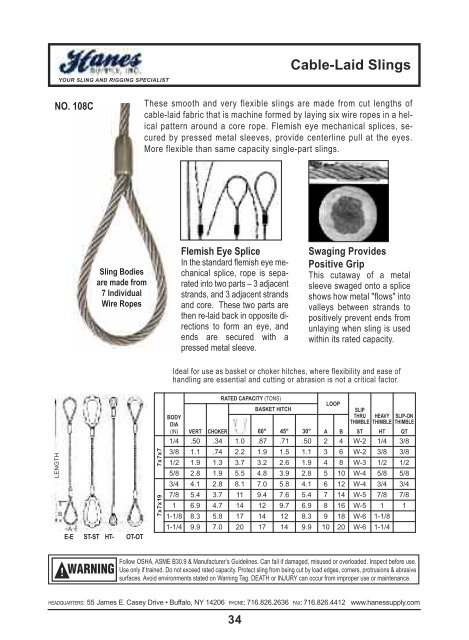

YOUR SLING AND RIGGING SPECIALISTcable-laid <strong>sl<strong>in</strong>gs</strong>NO. 108CThese smooth and very flexible <strong>sl<strong>in</strong>gs</strong> are made from cut lengths ofcable-laid fabric that is mach<strong>in</strong>e formed by lay<strong>in</strong>g six wire ropes <strong>in</strong> a helicalpattern around a core rope. Flemish eye mechanical splices, securedby pressed metal sleeves, provide centerl<strong>in</strong>e pull at the eyes.More flexible than same capacity s<strong>in</strong>gle-part <strong>sl<strong>in</strong>gs</strong>.Sl<strong>in</strong>g Bodiesare made from7 IndividualWire RopesFlemish Eye SpliceIn the standard flemish eye mechanicalsplice, rope is separated<strong>in</strong>to two parts – 3 adjacentstrands, and 3 adjacent strandsand core. These two parts arethen re-laid back <strong>in</strong> opposite directionsto form an eye, andends are secured with apressed metal sleeve.Swag<strong>in</strong>g ProvidesPositive GripThis cutaway of a metalsleeve swaged onto a spliceshows how metal "flows" <strong>in</strong>tovalleys between strands topositively prevent ends fromunlay<strong>in</strong>g when sl<strong>in</strong>g is usedwith<strong>in</strong> its rated capacity.Ideal for use as basket or choker hitches, where flexibility and ease ofhandl<strong>in</strong>g are essential and cutt<strong>in</strong>g or abrasion is not a critical factor.LENGTHBAE-E ST-ST HT- OT-OT7x7x77x7x19RATED CAPACITY (TONS)LOOPBASKET HITCHSLIPBODYTHRU HEAVY SLIP-ONDIATHIMBLE THIMBLE THIMBLE(IN) VERT CHOKER60° 45° 30° A B ST HT QT1/4 .50 .34 1.0 .87 .71 .50 2 4 W-2 1/4 3/83/8 1.1 .74 2.2 1.9 1.5 1.1 3 6 W-2 3/8 3/81/2 1.9 1.3 3.7 3.2 2.6 1.9 4 8 W-3 1/2 1/25/8 2.8 1.9 5.5 4.8 3.9 2.8 5 10 W-4 5/8 5/83/4 4.1 2.8 8.1 7.0 5.8 4.1 6 12 W-4 3/4 3/47/8 5.4 3.7 11 9.4 7.6 5.4 7 14 W-5 7/8 7/81 6.9 4.7 14 12 9.7 6.9 8 16 W-5 1 11-1/8 8.3 5.8 17 14 12 8.3 9 18 W-6 1-1/81-1/4 9.9 7.0 20 17 14 9.9 10 20 W-6 1-1/4Follow OSHA, ASME B30.9 & Manufacturer’s Guidel<strong>in</strong>es. Can fail if damaged, misused or overloaded. Inspect before use.Use only if tra<strong>in</strong>ed. Do not exceed rated capacity. Protect sl<strong>in</strong>g from be<strong>in</strong>g cut by load edges, corners, protrusions & abrasive! WARNINGsurfaces. Avoid environments stated on Warn<strong>in</strong>g Tag. DEATH or INJURY can occur from improper use or ma<strong>in</strong>tenance.HEADQUARTERS: 55 James E. Casey Drive • Buffalo, NY 14206 PHONE: 716.826.2636 FAX: 716.826.4412 www.hanessupply.com34