twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

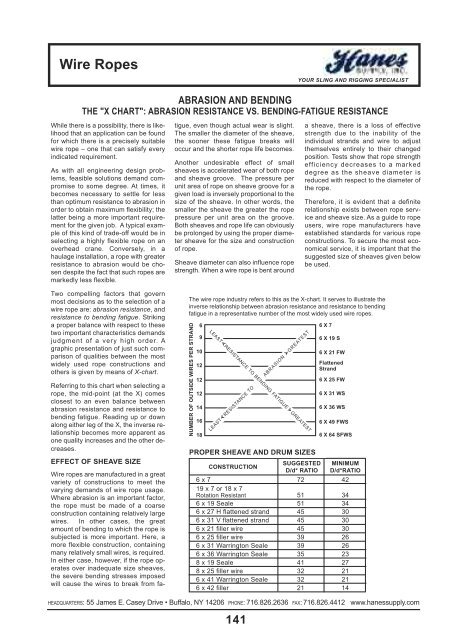

Wire RopesYOUR SLING AND RIGGING SPECIALISTABRASION AND BENDINGTHE "X CHART": ABRASION RESISTANCE VS. BENDING-FATIGUE RESISTANCEWhile there is a possibility, there is likelihoodthat an application can be foundfor which there is a precisely suitablewire rope – one that can satisfy every<strong>in</strong>dicated requirement.As with all eng<strong>in</strong>eer<strong>in</strong>g design problems,feasible solutions demand compromiseto some degree. At times, itbecomes necessary to settle for lessthan optimum resistance to abrasion <strong>in</strong>order to obta<strong>in</strong> maximum flexibility; thelatter be<strong>in</strong>g a more important requirementfor the given job. A typical exampleof this k<strong>in</strong>d of trade-off would be <strong>in</strong>select<strong>in</strong>g a highly flexible rope on anoverhead crane. Conversely, <strong>in</strong> ahaulage <strong>in</strong>stallation, a rope with greaterresistance to abrasion would be chosendespite the fact that such ropes aremarkedly less flexible.tigue, even though actual wear is slight.The smaller the diameter of the sheave,the sooner these fatigue breaks willoccur and the shorter rope life becomes.Another undesirable effect of smallsheaves is accelerated wear of both ropeand sheave groove. The pressure perunit area of rope on sheave groove for agiven load is <strong>in</strong>versely proportional to thesize of the sheave. In other words, thesmaller the sheave the greater the ropepressure per unit area on the groove.Both sheaves and rope life can obviouslybe prolonged by us<strong>in</strong>g the proper diametersheave for the size and constructionof rope.Sheave diameter can also <strong>in</strong>fluence ropestrength. When a wire rope is bent arounda sheave, there is a loss of effectivestrength due to the <strong>in</strong>ability of the<strong>in</strong>dividual strands and wire to adjustthemselves entirely to their changedposition. Tests show that rope strengthefficiency decreases to a markeddegree as the sheave diameter isreduced with respect to the diameter ofthe rope.Therefore, it is evident that a def<strong>in</strong>iterelationship exists between rope serviceand sheave size. As a guide to ropeusers, wire rope manufacturers haveestablished standards for various ropeconstructions. To secure the most economicalservice, it is important that thesuggested size of sheaves given belowbe used.Two compell<strong>in</strong>g factors that governmost decisions as to the selection of awire rope are: abrasion resistance, andresistance to bend<strong>in</strong>g fatigue. Strik<strong>in</strong>ga proper balance with respect to thesetwo important characteristics demandsjudgment of a very high order. Agraphic presentation of just such comparisonof qualities between the mostwidely used rope constructions andothers is given by means of X-chart.Referr<strong>in</strong>g to this chart when select<strong>in</strong>g arope, the mid-po<strong>in</strong>t (at the X) comesclosest to an even balance betweenabrasion resistance and resistance tobend<strong>in</strong>g fatigue. Read<strong>in</strong>g up or downalong either leg of the X, the <strong>in</strong>verse relationshipbecomes more apparent asone quality <strong>in</strong>creases and the other decreases.effect of sHeaVe sIzeWire ropes are manufactured <strong>in</strong> a greatvariety of constructions to meet thevary<strong>in</strong>g demands of wire rope usage.Where abrasion is an important factor,the rope must be made of a coarseconstruction conta<strong>in</strong><strong>in</strong>g relatively largewires. In other cases, the greatamount of bend<strong>in</strong>g to which the rope issubjected is more important. Here, amore flexible construction, conta<strong>in</strong><strong>in</strong>gmany relatively small wires, is required.In either case, however, if the rope operatesover <strong>in</strong>adequate size sheaves,the severe bend<strong>in</strong>g stresses imposedwill cause the wires to break from fa-The wire rope <strong>in</strong>dustry refers to this as the X-chart. It serves to illustrate the<strong>in</strong>verse relationship between abrasion resistance and resistance to bend<strong>in</strong>gfatigue <strong>in</strong> a representative number of the most widely used wire ropes.nUMbeR of oUtsIDe WIRes PeR stRanD6910121212141618LEAST×RESISTANCE TO BENDING FATIGUE Ø GREATESTLEAST× RESISTANCE TO ABRASION ØGREATESTPRoPeR sHeaVe anD DRUM sIzes6 X 76 X 19 s6 X 21 fWflattenedstrand6 X 25 fW6 X 31 Ws6 X 36 Ws6 X 49 fWs6 X 64 sfWsconstRUctIonsUGGesteD MInIMUMD/d* RatIo D/d*RatIo6 x 7 72 4219 x 7 or 18 x 7Rotation Resistant 51 346 x 19 Seale 51 346 x 27 H flattened strand 45 306 x 31 V flattened strand 45 306 x 21 filler wire 45 306 x 25 filler wire 39 266 x 31 Warr<strong>in</strong>gton Seale 39 266 x 36 Warr<strong>in</strong>gton Seale 35 238 x 19 Seale 41 278 x 25 filler wire 32 216 x 41 Warr<strong>in</strong>gton Seale 32 216 x 42 filler 21 14HEADQUARTERS: 55 James E. Casey Drive • Buffalo, NY 14206 PHONE: 716.826.2636 FAX: 716.826.4412 www.hanessupply.com141