twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

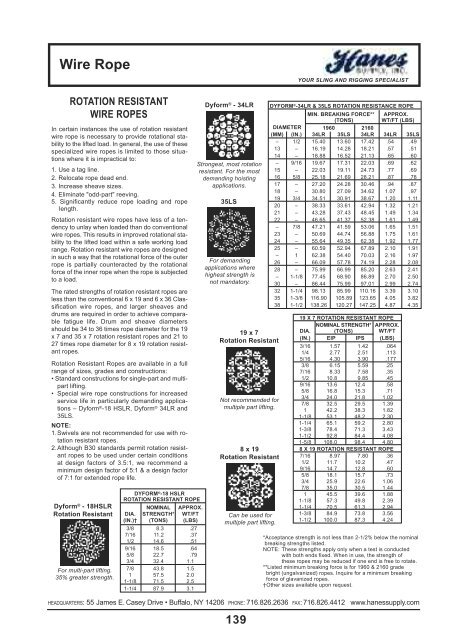

Wire RopeYOUR SLING AND RIGGING SPECIALISTROTATION RESISTANTWIRE ROPESIn certa<strong>in</strong> <strong>in</strong>stances the use of rotation resistantwire rope is necessary to provide rotational stabilityto the lifted load. In general, the use of thesespecialized wire ropes is limited to those situationswhere it is impractical to:1. Use a tag l<strong>in</strong>e.2. Relocate rope dead end.3. <strong>Inc</strong>rease sheave sizes.4. Elim<strong>in</strong>ate "odd-part" reev<strong>in</strong>g.5. Significantly reduce rope load<strong>in</strong>g and ropelength.Rotation resistant wire ropes have less of a tendencyto unlay when loaded than do conventionalwire ropes. This results <strong>in</strong> improved rotational stabilityto the lifted load with<strong>in</strong> a safe work<strong>in</strong>g loadrange. Rotation resistant wire ropes are designed<strong>in</strong> such a way that the rotational force of the outerrope is partially counteracted by the rotationalforce of the <strong>in</strong>ner rope when the rope is subjectedto a load.The rated strengths of rotation resistant ropes areless than the conventional 6 x 19 and 6 x 36 Classificationwire ropes, and larger sheaves anddrums are required <strong>in</strong> order to achieve comparablefatigue life. Drum and sheave diametersshould be 34 to 36 times rope diameter for the 19x 7 and 35 x 7 rotation resistant ropes and 21 to27 times rope diameter for 8 x 19 rotation resistantropes.Rotation Resistant Ropes are available <strong>in</strong> a fullrange of sizes, grades and constructions:• Standard constructions for s<strong>in</strong>gle-part and multipartlift<strong>in</strong>g.• Special wire rope constructions for <strong>in</strong>creasedservice life <strong>in</strong> particularly demand<strong>in</strong>g applications– Dyform ® -18 HSLR, Dyform ® 34LR and35LS.note:1.Swivels are not recommended for use with rotationresistant ropes.2.Although B30 standards permit rotation resistantropes to be used under certa<strong>in</strong> conditionsat design factors of 3.5:1, we recommend am<strong>in</strong>imum design factor of 5:1 & a design factorof 7:1 for extended rope life.Dyform ® - 18HslRRotation ResistantFor multi-part lift<strong>in</strong>g.35% greater strength.DYfoRM ® -18 HslRRotatIon ResIstant RoPenoMInal aPPRoX.DIa. stRenGtH* Wt/ft(In.)† (tons) (lbs)3/8 8.3 .277/16 11.2 .371/2 14.6 .519/16 18.5 .645/8 22.7 .793/4 32.4 1.17/8 43.8 1.51 57.5 2.01-1/8 71.5 2.51-1/4 87.9 3.1Dyform ® - 34lRStrongest, most rotationresistant. For the mostdemand<strong>in</strong>g hoist<strong>in</strong>gapplications.35lsFor demand<strong>in</strong>gapplications wherehighest strength isnot mandatory.19 x 7Rotation ResistantNot recommended formultiple part lift<strong>in</strong>g.8 x 19Rotation ResistantCan be used formultiple part lift<strong>in</strong>g.HEADQUARTERS: 55 James E. Casey Drive • Buffalo, NY 14206 PHONE: 716.826.2636 FAX: 716.826.4412 www.hanessupply.com139DYfoRM ® -34lR & 35ls RotatIon ResIstance RoPeMIn. bReakInG foRce** aPPRoX.(tons)Wt/ft (lbs)DIaMeteR 1960 2160(MM) (In.) 34lR 35ls 34lR 34lR 35ls– 1/2 15.40 13.60 17.42 .54 .4913 – 16.19 14.28 18.21 .57 .5114 – 18.88 16.52 21.13 .65 .60– 9/16 19.67 17.31 22.03 .69 .6215 – 22.03 19.11 24.73 .77 .6916 5/8 25.18 21.69 28.21 .87 .7817 – 27.20 24.28 30.46 .94 .8718 – 30.80 27.09 34.62 1.07 .9719 3/4 34.51 30.91 38.67 1.20 1.1120 – 38.33 33.61 42.94 1.32 1.2121 – 43.28 37.43 48.45 1.49 1.3422 – 46.65 41.37 52.38 1.61 1.49– 7/8 47.21 41.59 53.06 1.65 1.5123 – 50.69 44.74 56.88 1.75 1.6124 – 55.64 49.35 62.38 1.92 1.7725 – 60.59 52.94 67.89 2.10 1.91– 1 62.38 54.40 70.03 2.16 1.9726 – 66.09 57.78 74.19 2.28 2.0828 – 75.99 66.99 85.20 2.63 2.41– 1-1/8 77.45 68.90 86.89 2.70 2.5030 – 86.44 75.99 97.01 2.99 2.7432 1-1/4 98.13 85.99 110.16 3.39 3.1035 1-3/8 116.90 105.89 123.65 4.05 3.8238 1-1/2 138.26 120.27 147.25 4.87 4.3519 X 7 RotatIon ResIstant RoPenoMInal stRenGtH* aPPRoX.DIa. (tons) Wt/ft(In.) eIP IPs (lbs)3/16 1.57 1.42 .0641/4 2.77 2.51 .1135/16 4.30 3.90 .1773/8 6.15 5.59 .257/16 8.33 7.58 .351/2 10.8 9.85 .459/16 13.6 12.4 .585/8 16.8 15.3 .713/4 24.0 21.8 1.027/8 32.5 29.5 1.391 42.2 38.3 1.821-1/8 53.1 48.2 2.301-1/4 65.1 59.2 2.801-3/8 78.4 71.3 3.431-1/2 92.8 84.4 4.081-5/8 108.0 98.4 4.808 X 19 RotatIon ResIstant RoPe7/16 8.97 7.80 .361/2 11.7 10.2 .479/16 14.7 12.8 .605/8 18.1 15.7 .733/4 25.9 22.6 1.067/8 35.0 30.5 1.441 45.5 39.6 1.881-1/8 57.3 49.8 2.391-1/4 70.5 61.3 2.941-3/8 84.9 73.8 3.561-1/2 100.0 87.3 4.24*Acceptance strength is not less than 2-1/2% below the nom<strong>in</strong>albreak<strong>in</strong>g strengths listed.NOTE: These strengths apply only when a test is conductedwith both ends fixed. When <strong>in</strong> use, the strength ofthese ropes may be reduced if one end is free to rotate.**Listed m<strong>in</strong>imum break<strong>in</strong>g force is for 1960 & 2160 gradebright (ungalvanized) ropes. Inquire for a m<strong>in</strong>imum break<strong>in</strong>gforce of glavanized ropes.†Other sizes available upon request.