twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

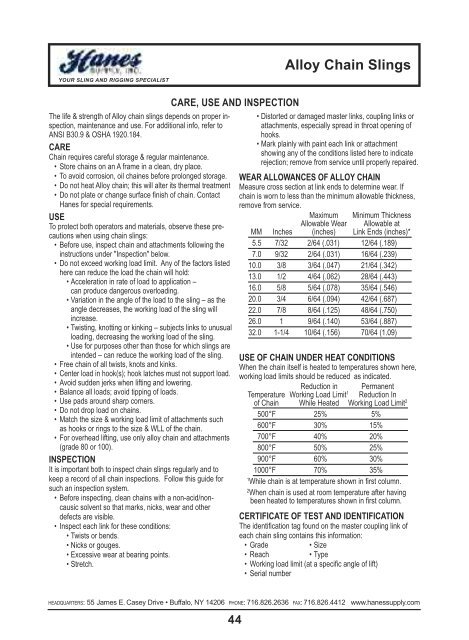

YOUR SLING AND RIGGING SPECIALISTalloy cha<strong>in</strong> <strong>sl<strong>in</strong>gs</strong>The life & strength of Alloy cha<strong>in</strong> <strong>sl<strong>in</strong>gs</strong> depends on proper <strong>in</strong>spection,ma<strong>in</strong>tenance and use. For additional <strong>in</strong>fo, refer toANSI B30.9 & OSHA 1920.184.CARECha<strong>in</strong> requires careful storage & regular ma<strong>in</strong>tenance.• Store cha<strong>in</strong>s on an A frame <strong>in</strong> a clean, dry place.• To avoid corrosion, oil cha<strong>in</strong>es before prolonged storage.• Do not heat Alloy cha<strong>in</strong>; this will alter its thermal treatment• Do not plate or change surface f<strong>in</strong>ish of cha<strong>in</strong>. Contact<strong>Hanes</strong> for special requirements.USETo protect both operators and materials, observe these precautionswhen us<strong>in</strong>g cha<strong>in</strong> <strong>sl<strong>in</strong>gs</strong>:• Before use, <strong>in</strong>spect cha<strong>in</strong> and attachments follow<strong>in</strong>g the<strong>in</strong>structions under "Inspection" below.• Do not exceed work<strong>in</strong>g load limit. Any of the factors listedhere can reduce the load the cha<strong>in</strong> will hold:• Acceleration <strong>in</strong> rate of load to application –can produce dangerous overload<strong>in</strong>g.• Variation <strong>in</strong> the angle of the load to the sl<strong>in</strong>g – as theangle decreases, the work<strong>in</strong>g load of the sl<strong>in</strong>g will<strong>in</strong>crease.• Twist<strong>in</strong>g, knott<strong>in</strong>g or k<strong>in</strong>k<strong>in</strong>g – subjects l<strong>in</strong>ks to unusualload<strong>in</strong>g, decreas<strong>in</strong>g the work<strong>in</strong>g load of the sl<strong>in</strong>g.• Use for purposes other than those for which <strong>sl<strong>in</strong>gs</strong> are<strong>in</strong>tended – can reduce the work<strong>in</strong>g load of the sl<strong>in</strong>g.• Free cha<strong>in</strong> of all twists, knots and k<strong>in</strong>ks.• Center load <strong>in</strong> hook(s); hook latches must not support load.• Avoid sudden jerks when lift<strong>in</strong>g and lower<strong>in</strong>g.• Balance all loads; avoid tipp<strong>in</strong>g of loads.• Use pads around sharp corners.• Do not drop load on cha<strong>in</strong>s.• Match the size & work<strong>in</strong>g load limit of attachments suchas hooks or r<strong>in</strong>gs to the size & WLL of the cha<strong>in</strong>.• For overhead lift<strong>in</strong>g, use only alloy cha<strong>in</strong> and attachments(grade 80 or 100).INSPECTIONIt is important both to <strong>in</strong>spect cha<strong>in</strong> <strong>sl<strong>in</strong>gs</strong> regularly and tokeep a record of all cha<strong>in</strong> <strong>in</strong>spections. Follow this guide forsuch an <strong>in</strong>spection system.• Before <strong>in</strong>spect<strong>in</strong>g, clean cha<strong>in</strong>s with a non-acid/noncausicsolvent so that marks, nicks, wear and otherdefects are visible.• Inspect each l<strong>in</strong>k for these conditions:• Twists or bends.• Nicks or gouges.• Excessive wear at bear<strong>in</strong>g po<strong>in</strong>ts.• Stretch.CARE, USE AND INSPECTION• Distorted or damaged master l<strong>in</strong>ks, coupl<strong>in</strong>g l<strong>in</strong>ks orattachments, especially spread <strong>in</strong> throat open<strong>in</strong>g ofhooks.• Mark pla<strong>in</strong>ly with pa<strong>in</strong>t each l<strong>in</strong>k or attachmentshow<strong>in</strong>g any of the conditions listed here to <strong>in</strong>dicaterejection; remove from service until properly repaired.WEAR ALLOWANCES OF ALLOY CHAINMeasure cross section at l<strong>in</strong>k ends to determ<strong>in</strong>e wear. Ifcha<strong>in</strong> is worn to less than the m<strong>in</strong>imum allowable thickness,remove from service.Maximum M<strong>in</strong>imum ThicknessAllowable Wear Allowable atMM <strong>Inc</strong>hes (<strong>in</strong>ches) L<strong>in</strong>k Ends (<strong>in</strong>ches)*5.5 7/32 2/64 (.031)– – – 12/64 (.189)7.0 9/32 2/64 (.031) 16/64 (.239)10.0 3/8 3/64 (.047) 21/64 (.342)13.0 1/2 4/64 (.062) 28/64 (.443)16.0 5/8 5/64 (.078) 35/64 (.546)20.0 3/4 6/64 (.094) 42/64 (.687)22.0 7/8 8/64 (.125) 48/64 (.750)26.0 1 9/64 (.140) 53/64 (.887)32.0 1-1/4 10/64 (.156) 70/64 (1.09)USE OF CHAIN UNDER HEAT CONDITIONSWhen the cha<strong>in</strong> itself is heated to temperatures shown here,work<strong>in</strong>g load limits should be reduced as <strong>in</strong>dicated.Reduction <strong>in</strong> PermanentTemperature Work<strong>in</strong>g Load Limit 1 Reduction Inof Cha<strong>in</strong> While Heated Work<strong>in</strong>g Load Limit 2500°F 25% 5%600°F 30% 15%700°F 40% 20%800°F 50% 25%900°F 60% 30%1000°F 70% 35%1While cha<strong>in</strong> is at temperature shown <strong>in</strong> first column.2When cha<strong>in</strong> is used at room temperature after hav<strong>in</strong>gbeen heated to temperatures shown <strong>in</strong> first column.CERTIFICATE OF TEST AND IDENTIFICATIONThe identification tag found on the master coupl<strong>in</strong>g l<strong>in</strong>k ofeach cha<strong>in</strong> sl<strong>in</strong>g conta<strong>in</strong>s this <strong>in</strong>formation:• Grade• Size• Reach• Type• Work<strong>in</strong>g load limit (at a specific angle of lift)• Serial numberHEADQUARTERS: 55 James E. Casey Drive • Buffalo, NY 14206 PHONE: 716.826.2636 FAX: 716.826.4412 www.hanessupply.com44