twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

twin-path® slings in action - Hanes Supply, Inc

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

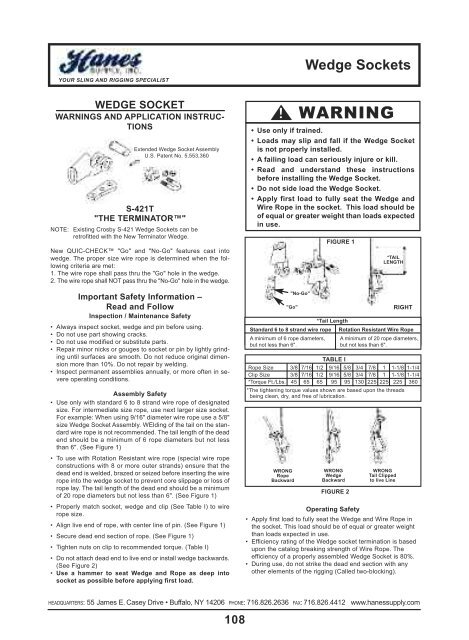

YOUR SLING AND RIGGING SPECIALISTWedge socketsWeDGe socketWaRnInGs anD aPPlIcatIon InstRUctIonsExtended Wedge Socket AssemblyU.S. Patent No. 5,553,360s-421t"tHe teRMInatoR"NOTE: Exist<strong>in</strong>g Crosby S-421 Wedge Sockets can beretrofitted with the New Term<strong>in</strong>ator Wedge.New QUIC-CHECK "Go" and "No-Go" features cast <strong>in</strong>towedge. The proper size wire rope is determ<strong>in</strong>ed when the follow<strong>in</strong>gcriteria are met:1. The wire rope shall pass thru the "Go" hole <strong>in</strong> the wedge.2. The wire rope shall NOT pass thru the "No-Go" hole <strong>in</strong> the wedge.Important safety Information –Read and followInspection / Ma<strong>in</strong>tenance safety• Always <strong>in</strong>spect socket, wedge and p<strong>in</strong> before us<strong>in</strong>g.• Do not use part show<strong>in</strong>g cracks.• Do not use modified or substitute parts.• Repair m<strong>in</strong>or nicks or gouges to socket or p<strong>in</strong> by lightly gr<strong>in</strong>d<strong>in</strong>guntil surfaces are smooth. Do not reduce orig<strong>in</strong>al dimensionmore than 10%. Do not repair by weld<strong>in</strong>g.• Inspect permanent assemblies annually, or more often <strong>in</strong> severeoperat<strong>in</strong>g conditions.assembly safety• Use only with standard 6 to 8 strand wire rope of designatedsize. For <strong>in</strong>termediate size rope, use next larger size socket.For example: When us<strong>in</strong>g 9/16" diameter wire rope use a 5/8"size Wedge Socket Assembly. WEld<strong>in</strong>g of the tail on the standardwire rope is not recommended. The tail length of the deadend should be a m<strong>in</strong>imum of 6 rope diameters but not lessthan 6". (See Figure 1)• To use with Rotation Resistant wire rope (special wire ropeconstructions with 8 or more outer strands) ensure that thedead end is welded, brazed or seized before <strong>in</strong>sert<strong>in</strong>g the wirerope <strong>in</strong>to the wedge socket to prevent core slippage or loss ofrope lay. The tail length of the dead end should be a m<strong>in</strong>imumof 20 rope diameters but not less than 6". (See Figure 1)• Properly match socket, wedge and clip (See Table I) to wirerope size.• Align live end of rope, with center l<strong>in</strong>e of p<strong>in</strong>. (See Figure 1)• Secure dead end section of rope. (See Figure 1)• Tighten nuts on clip to recommended torque. (Table I)• Do not attach dead end to live end or <strong>in</strong>stall wedge backwards.(See Figure 2)• Use a hammer to seat Wedge and Rope as deep <strong>in</strong>tosocket as possible before apply<strong>in</strong>g first load.!• Use only if tra<strong>in</strong>ed.• loads may slip and fall if the Wedge socketis not properly <strong>in</strong>stalled.• a fail<strong>in</strong>g load can seriously <strong>in</strong>jure or kill.• Read and understand these <strong>in</strong>structionsbefore <strong>in</strong>stall<strong>in</strong>g the Wedge socket.• Do not side load the Wedge socket.• apply first load to fully seat the Wedge andWire Rope <strong>in</strong> the socket. this load should beof equal or greater weight than loads expected<strong>in</strong> use."no-Go""Go"fIGURe 1*taIllenGtHRIGHt*tail lengthstandard 6 to 8 strand wire rope Rotation Resistant Wire RopeA m<strong>in</strong>imum of 6 rope diameters, A m<strong>in</strong>imum of 20 rope diameters,but not less than 6". but not less than 6".table IRope Size 3/8 7/16 1/2 9/16 5/8 3/4 7/8 1 1-1/8 1-1/4Clip Size 3/8 7/16 1/2 9/16 5/8 3/4 7/8 1 1-1/8 1-1/4*Torque Ft./Lbs. 45 65 65 95 95 130 225 225 225 360*The tighten<strong>in</strong>g torque values shown are based upon the threadsbe<strong>in</strong>g clean, dry, and free of lubrication.WRonGRopebackwardWARNINGWRonGWedgebackwardfIGURe 2WRonGtail clippedto live l<strong>in</strong>eoperat<strong>in</strong>g safety• Apply first load to fully seat the Wedge and Wire Rope <strong>in</strong>the socket. This load should be of equal or greater weightthan loads expected <strong>in</strong> use.• Efficiency rat<strong>in</strong>g of the Wedge socket term<strong>in</strong>ation is basedupon the catalog break<strong>in</strong>g strength of Wire Rope. Theefficiency of a properly assembled Wedge Socket is 80%.• Dur<strong>in</strong>g use, do not strike the dead end section with anyother elements of the rigg<strong>in</strong>g (Called two-block<strong>in</strong>g).HEADQUARTERS: 55 James E. Casey Drive • Buffalo, NY 14206 PHONE: 716.826.2636 FAX: 716.826.4412 www.hanessupply.com108