Heavy Duty Balanced Opposed Compressors

Heavy Duty Balanced Opposed Compressors

Heavy Duty Balanced Opposed Compressors

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FOR MODELS: JG AND JGA SECTION 1 - DESIGN SPECIFICATIONS & DATA<br />

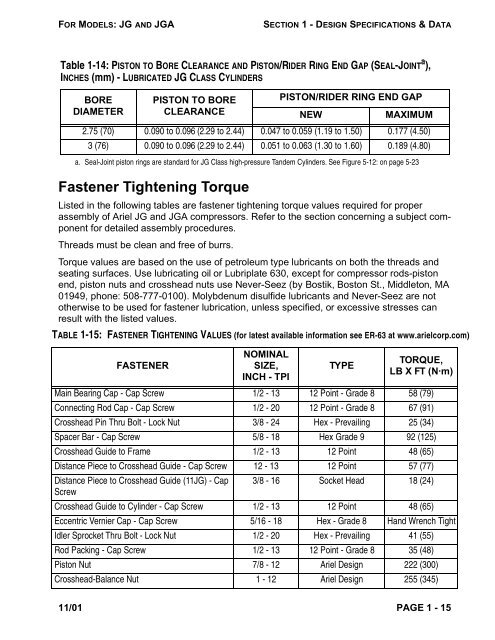

Table 1-14: PISTON TO BORE CLEARANCE AND PISTON/RIDER RING END GAP (SEAL-JOINT a ),<br />

INCHES (mm) - LUBRICATED JG CLASS CYLINDERS<br />

BORE<br />

DIAMETER<br />

PISTON TO BORE<br />

CLEARANCE<br />

a. Seal-Joint piston rings are standard for JG Class high-pressure Tandem Cylinders. See Figure 5-12: on page 5-23<br />

Fastener Tightening Torque<br />

Listed in the following tables are fastener tightening torque values required for proper<br />

assembly of Ariel JG and JGA compressors. Refer to the section concerning a subject component<br />

for detailed assembly procedures.<br />

Threads must be clean and free of burrs.<br />

PISTON/RIDER RING END GAP<br />

NEW MAXIMUM<br />

2.75 (70) 0.090 to 0.096 (2.29 to 2.44) 0.047 to 0.059 (1.19 to 1.50) 0.177 (4.50)<br />

3 (76) 0.090 to 0.096 (2.29 to 2.44) 0.051 to 0.063 (1.30 to 1.60) 0.189 (4.80)<br />

Torque values are based on the use of petroleum type lubricants on both the threads and<br />

seating surfaces. Use lubricating oil or Lubriplate 630, except for compressor rods-piston<br />

end, piston nuts and crosshead nuts use Never-Seez (by Bostik, Boston St., Middleton, MA<br />

01949, phone: 508-777-0100). Molybdenum disulfide lubricants and Never-Seez are not<br />

otherwise to be used for fastener lubrication, unless specified, or excessive stresses can<br />

result with the listed values.<br />

TABLE 1-15: FASTENER TIGHTENING VALUES (for latest available information see ER-63 at www.arielcorp.com)<br />

FASTENER<br />

NOMINAL<br />

SIZE,<br />

INCH - TPI<br />

TYPE<br />

TORQUE,<br />

LB X FT (N·m)<br />

Main Bearing Cap - Cap Screw 1/2 - 13 12 Point - Grade 8 58 (79)<br />

Connecting Rod Cap - Cap Screw 1/2 - 20 12 Point - Grade 8 67 (91)<br />

Crosshead Pin Thru Bolt - Lock Nut 3/8 - 24 Hex - Prevailing 25 (34)<br />

Spacer Bar - Cap Screw 5/8 - 18 Hex Grade 9 92 (125)<br />

Crosshead Guide to Frame 1/2 - 13 12 Point 48 (65)<br />

Distance Piece to Crosshead Guide - Cap Screw 12 - 13 12 Point 57 (77)<br />

Distance Piece to Crosshead Guide (11JG) - Cap<br />

Screw<br />

3/8 - 16 Socket Head 18 (24)<br />

Crosshead Guide to Cylinder - Cap Screw 1/2 - 13 12 Point 48 (65)<br />

Eccentric Vernier Cap - Cap Screw 5/16 - 18 Hex - Grade 8 Hand Wrench Tight<br />

Idler Sprocket Thru Bolt - Lock Nut 1/2 - 20 Hex - Prevailing 41 (55)<br />

Rod Packing - Cap Screw 1/2 - 13 12 Point - Grade 8 35 (48)<br />

Piston Nut 7/8 - 12 Ariel Design 222 (300)<br />

Crosshead-Balance Nut 1 - 12 Ariel Design 255 (345)<br />

11/01 PAGE 1 - 15