Heavy Duty Balanced Opposed Compressors

Heavy Duty Balanced Opposed Compressors

Heavy Duty Balanced Opposed Compressors

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FOR MODELS: JG AND JGA SECTION 5 - MAINTENANCE<br />

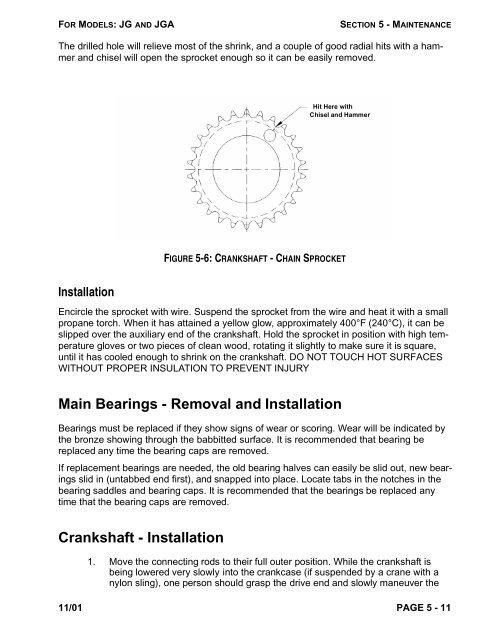

The drilled hole will relieve most of the shrink, and a couple of good radial hits with a hammer<br />

and chisel will open the sprocket enough so it can be easily removed.<br />

Installation<br />

Encircle the sprocket with wire. Suspend the sprocket from the wire and heat it with a small<br />

propane torch. When it has attained a yellow glow, approximately 400°F (240°C), it can be<br />

slipped over the auxiliary end of the crankshaft. Hold the sprocket in position with high temperature<br />

gloves or two pieces of clean wood, rotating it slightly to make sure it is square,<br />

until it has cooled enough to shrink on the crankshaft. DO NOT TOUCH HOT SURFACES<br />

WITHOUT PROPER INSULATION TO PREVENT INJURY<br />

Main Bearings - Removal and Installation<br />

Bearings must be replaced if they show signs of wear or scoring. Wear will be indicated by<br />

the bronze showing through the babbitted surface. It is recommended that bearing be<br />

replaced any time the bearing caps are removed.<br />

If replacement bearings are needed, the old bearing halves can easily be slid out, new bearings<br />

slid in (untabbed end first), and snapped into place. Locate tabs in the notches in the<br />

bearing saddles and bearing caps. It is recommended that the bearings be replaced any<br />

time that the bearing caps are removed.<br />

Crankshaft - Installation<br />

Hit Here with<br />

Chisel and Hammer<br />

FIGURE 5-6: CRANKSHAFT - CHAIN SPROCKET<br />

1. Move the connecting rods to their full outer position. While the crankshaft is<br />

being lowered very slowly into the crankcase (if suspended by a crane with a<br />

nylon sling), one person should grasp the drive end and slowly maneuver the<br />

11/01 PAGE 5 - 11