Heavy Duty Balanced Opposed Compressors

Heavy Duty Balanced Opposed Compressors

Heavy Duty Balanced Opposed Compressors

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FOR MODELS: JG AND JGA SECTION 4 - LUBRICATION AND VENTING<br />

Lube Oil Strainer, Filter & Filter Installation Instructions<br />

Lube Oil Strainer<br />

The strainer is located on the auxiliary end of the crankcase below the oil level. The strainer<br />

basket should be taken out and washed in an appropriate solvent whenever the lubricating<br />

oil is changed.<br />

Lube Oil Filter<br />

Ariel recommends replacing filter element when differential pressure reaches approximately<br />

10 PSI (70 kPa) across the filter at normal operating temperatures or at six month intervals.<br />

Filter Element Installation Instructions<br />

1. Clean filter base surface, and be certain old gasket is removed.<br />

2 Fill filter with clean oil using the same grade oil as in the crankcase.<br />

3 Apply clean lube oil to the filter gasket.<br />

4 After the filter gasket contacts the base, tighten one turn.<br />

5 After starting the unit, check for leaks, and retighten if necessary.<br />

6 Do not run unit with a damaged filter can. It can fracture or leak. Replace only<br />

with an Ariel approved filter.<br />

NOTE: FAILURE TO FILL FILTER VESSEL WITH OIL, PRIOR TO STARTING, CAN<br />

CAUSE SEVERE DAMAGE TO THE COMPRESSOR.<br />

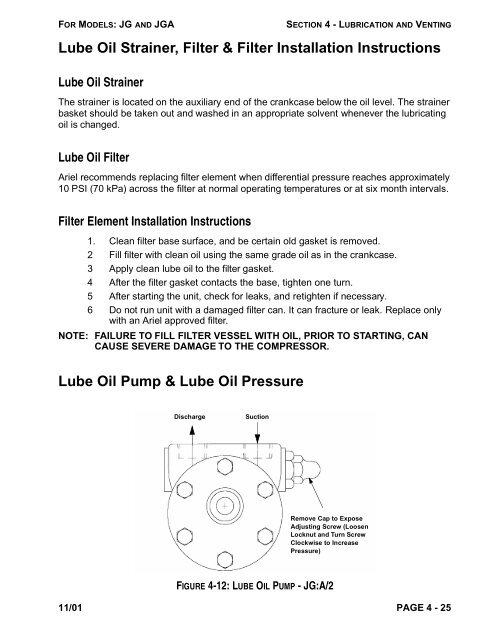

Lube Oil Pump & Lube Oil Pressure<br />

Discharge Suction<br />

Remove Cap to Expose<br />

Adjusting Screw (Loosen<br />

Locknut and Turn Screw<br />

Clockwise to Increase<br />

Pressure)<br />

FIGURE 4-12: LUBE OIL PUMP - JG:A/2<br />

11/01 PAGE 4 - 25