MEP-Technical Manual CDN 0408.qxd - Hambro

MEP-Technical Manual CDN 0408.qxd - Hambro

MEP-Technical Manual CDN 0408.qxd - Hambro

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

18<br />

DESIGN PRINCIPLES AND CALCULATIONS<br />

4.8 MINI-JOISTS<br />

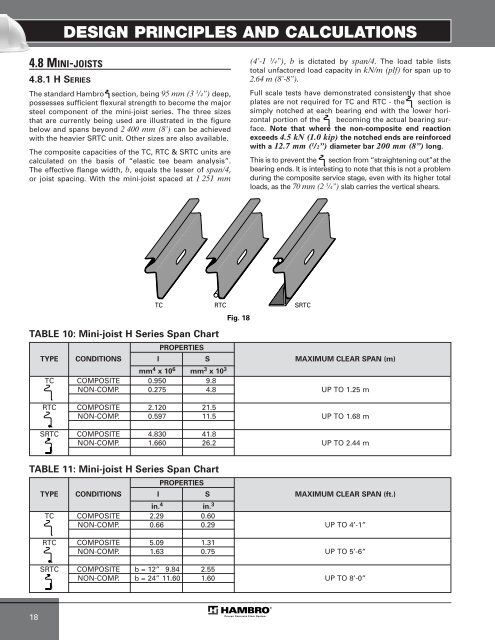

4.8.1 H SERIES<br />

The standard <strong>Hambro</strong> section, being 95 mm (3 3 /4”) deep,<br />

possesses sufficient flexural strength to become the major<br />

steel component of the mini-joist series. The three sizes<br />

that are currently being used are illustrated in the figure<br />

below and spans beyond 2 400 mm (8’) can be achieved<br />

with the heavier SRTC unit. Other sizes are also available.<br />

The composite capacities of the TC, RTC & SRTC units are<br />

calculated on the basis of “elastic tee beam analysis”.<br />

The effective flange width, b, equals the lesser of span/4,<br />

or joist spacing. With the mini-joist spaced at 1 251 mm<br />

TABLE 10: Mini-joist H Series Span Chart<br />

TC RTC SRTC<br />

PROPERTIES<br />

Fig. 18<br />

(4’-1 1 /4”), b is dictated by span/4. The load table lists<br />

total unfactored load capacity in kN/m (plf) for span up to<br />

2.64 m (8’-8”).<br />

Full scale tests have demonstrated consistently that shoe<br />

plates are not required for TC and RTC - the section is<br />

simply notched at each bearing end with the lower horizontal<br />

portion of the becoming the actual bearing surface.<br />

Note that where the non-composite end reaction<br />

exceeds 4.5 kN (1.0 kip) the notched ends are reinforced<br />

with a 12.7 mm ( 1 /2”) diameter bar 200 mm (8”) long.<br />

This is to prevent the section from “straightening out”at the<br />

bearing ends. It is interesting to note that this is not a problem<br />

during the composite service stage, even with its higher total<br />

loads, as the 70 mm (2 3 /4”) slab carries the vertical shears.<br />

TYPE CONDITIONS I S MAXIMUM CLEAR SPAN (m)<br />

mm 4 x 10 6 mm 3 x 10 3<br />

TC COMPOSITE 0.950 9.8<br />

NON-COMP. 0.275 4.8 UP TO 1.25 m<br />

RTC COMPOSITE 2.120 21.5<br />

NON-COMP. 0.597 11.5 UP TO 1.68 m<br />

SRTC COMPOSITE 4.830 41.8<br />

NON-COMP. 1.660 26.2 UP TO 2.44 m<br />

TABLE 11: Mini-joist H Series Span Chart<br />

PROPERTIES<br />

TYPE CONDITIONS I S MAXIMUM CLEAR SPAN (ft.)<br />

in. 4 in. 3<br />

TC COMPOSITE 2.29 0.60<br />

NON-COMP. 0.66 0.29 UP TO 4’-1”<br />

RTC COMPOSITE 5.09 1.31<br />

NON-COMP. 1.63 0.75 UP TO 5’-6”<br />

SRTC COMPOSITE b = 12” 9.84 2.55<br />

NON-COMP. b = 24” 11.60 1.60 UP TO 8’-0”