MEP-Technical Manual CDN 0408.qxd - Hambro

MEP-Technical Manual CDN 0408.qxd - Hambro

MEP-Technical Manual CDN 0408.qxd - Hambro

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

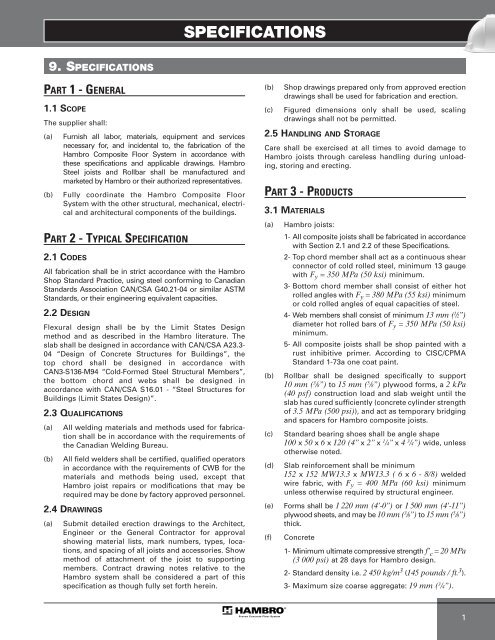

9. SPECIFICATIONS<br />

PART 1-GENERAL<br />

1.1 SCOPE<br />

The supplier shall:<br />

(a) Furnish all labor, materials, equipment and services<br />

necessary for, and incidental to, the fabrication of the<br />

<strong>Hambro</strong> Composite Floor System in accordance with<br />

these specifications and applicable drawings. <strong>Hambro</strong><br />

Steel joists and Rollbar shall be manufactured and<br />

marketed by <strong>Hambro</strong> or their authorized representatives.<br />

(b) Fully coordinate the <strong>Hambro</strong> Composite Floor<br />

System with the other structural, mechanical, electrical<br />

and architectural components of the buildings.<br />

PART 2 - TYPICAL SPECIFICATION<br />

2.1 CODES<br />

All fabrication shall be in strict accordance with the <strong>Hambro</strong><br />

Shop Standard Practice, using steel conforming to Canadian<br />

Standards Association CAN/CSA G40.21-04 or similar ASTM<br />

Standards, or their engineering equivalent capacities.<br />

2.2 DESIGN<br />

Flexural design shall be by the Limit States Design<br />

method and as described in the <strong>Hambro</strong> literature. The<br />

slab shall be designed in accordance with CAN/CSA A23.3-<br />

04 “Design of Concrete Structures for Buildings”, the<br />

top chord shall be designed in accordance with<br />

CAN3-S136-M94 “Cold-Formed Steel Structural Members”,<br />

the bottom chord and webs shall be designed in<br />

accordance with CAN/CSA S16.01 - “Steel Structures for<br />

Buildings (Limit States Design)”.<br />

2.3 QUALIFICATIONS<br />

(a) All welding materials and methods used for fabrication<br />

shall be in accordance with the requirements of<br />

the Canadian Welding Bureau.<br />

(b) All field welders shall be certified, qualified operators<br />

in accordance with the requirements of CWB for the<br />

materials and methods being used, except that<br />

<strong>Hambro</strong> joist repairs or modifications that may be<br />

required may be done by factory approved personnel.<br />

2.4 DRAWINGS<br />

(a) Submit detailed erection drawings to the Architect,<br />

Engineer or the General Contractor for approval<br />

showing material lists, mark numbers, types, locations,<br />

and spacing of all joists and accessories. Show<br />

method of attachment of the joist to supporting<br />

members. Contract drawing notes relative to the<br />

<strong>Hambro</strong> system shall be considered a part of this<br />

specification as though fully set forth herein.<br />

SPECIFICATIONS<br />

(b) Shop drawings prepared only from approved erection<br />

drawings shall be used for fabrication and erection.<br />

(c) Figured dimensions only shall be used, scaling<br />

drawings shall not be permitted.<br />

2.5 HANDLING AND STORAGE<br />

Care shall be exercised at all times to avoid damage to<br />

<strong>Hambro</strong> joists through careless handling during unloading,<br />

storing and erecting.<br />

PART 3 - PRODUCTS<br />

3.1 MATERIALS<br />

(a) <strong>Hambro</strong> joists:<br />

1- All composite joists shall be fabricated in accordance<br />

with Section 2.1 and 2.2 of these Specifications.<br />

2- Top chord member shall act as a continuous shear<br />

connector of cold rolled steel, minimum 13 gauge<br />

with Fy = 350 MPa (50 ksi) minimum.<br />

3- Bottom chord member shall consist of either hot<br />

rolled angles with Fy = 380 MPa (55 ksi) minimum<br />

or cold rolled angles of equal capacities of steel.<br />

4- Web members shall consist of minimum 13 mm ( 1 /2”)<br />

diameter hot rolled bars of Fy = 350 MPa (50 ksi)<br />

minimum.<br />

5- All composite joists shall be shop painted with a<br />

rust inhibitive primer. According to CISC/CPMA<br />

Standard 1-73a one coat paint.<br />

(b) Rollbar shall be designed specifically to support<br />

10 mm ( 3 /8”) to 15 mm ( 5 /8”) plywood forms, a 2 kPa<br />

(40 psf) construction load and slab weight until the<br />

slab has cured sufficiently (concrete cylinder strength<br />

of 3.5 MPa (500 psi)), and act as temporary bridging<br />

and spacers for <strong>Hambro</strong> composite joists.<br />

(c) Standard bearing shoes shall be angle shape<br />

100 x 50 x 6 x 120 (4” x 2” x 1 /4” x 4 3 /4”) wide, unless<br />

otherwise noted.<br />

(d) Slab reinforcement shall be minimum<br />

152 x 152 MW13.3 x MW13.3 ( 6 x 6 - 8/8) welded<br />

wire fabric, with Fy = 400 MPa (60 ksi) minimum<br />

unless otherwise required by structural engineer.<br />

(e) Forms shall be 1 220 mm (4’-0”) or 1 500 mm (4’-11”)<br />

plywood sheets, and may be 10 mm ( 3 /8”) to 15 mm ( 5 /8”)<br />

thick.<br />

(f) Concrete<br />

1- Minimum ultimate compressive strength f’ c = 20 MPa<br />

(3 000 psi) at 28 days for <strong>Hambro</strong> design.<br />

2- Standard density i.e. 2 450 kg/m3 (145 pounds / ft. 3 ).<br />

3- Maximum size coarse aggregate: 19 mm ( 3 /4”).<br />

1