OS-C501

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Offshore Standard DNV-<strong>OS</strong>-<strong>C501</strong>, November 2013<br />

App.B Lay-up and laminate specification – Page 213<br />

APPENDIX B LAY-UP AND LAMINATE SPECIFICATION<br />

B.1 Unique definition of a laminate<br />

B.1.1<br />

B.1.1.1 It is important to characterise a laminate in an unambiguous way. All constituent materials have to be<br />

identified.<br />

B.1.1.2 A composite laminate is generally made of a number of layers stacked on top of each other. These<br />

layers can consist of complicated or simple fibre arrangements. The layers are the units that are physically<br />

stacked in the production process.<br />

B.1.1.3 The basic building block of a laminate is the ply (lamina). The ply is an orthotropic material and its<br />

properties are needed for laminate analysis.<br />

B.1.1.4 If reinforcement fabrics are not the same (e.g. a multi axial fabric), both should be identified in a<br />

laminate.<br />

Guidance note:<br />

A tri-axial fabric is typically specified as one fabric layer in production. The orientation of the fabric in the laminate<br />

is given with respect to the long axis of the fabric role. However, for laminate calculations the tri-axial fabric shall be<br />

described as three orthotropic unidirectional plies.<br />

---e-n-d---of---G-u-i-d-a-n-c-e---n-o-t-e---<br />

B.1.1.5 The axis of the ply co-ordinate system of each ply shall to be clearly identified.<br />

B.1.1.6 The type of the reinforcement and the weight per area in each ply shall be given.<br />

B.1.1.7 The stacking sequence of the laminate shall be clearly described. Each ply shall be identified and its<br />

orientation in the laminate shall be described. Usually a laminate co-ordinate system x, y, z is chosen. The z-<br />

axis is the through the thickness direction. The orientation of the main reinforcement direction of the plies (1-<br />

direction) is given relative to the x-direction of the laminate.<br />

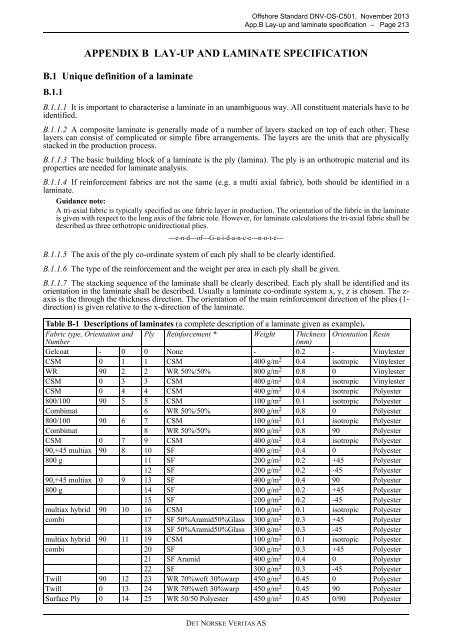

Table B-1 Descriptions of laminates (a complete description of a laminate given as example).<br />

Fabric type, Orientation and Ply Reinforcement * Weight Thickness Orientation Resin<br />

Number<br />

(mm)<br />

Gelcoat - 0 0 None - 0.2 - Vinylester<br />

CSM 0 1 1 CSM 400 g/m 2 0.4 isotropic Vinylester<br />

WR 90 2 2 WR 50%/50% 800 g/m 2 0.8 0 Vinylester<br />

CSM 0 3 3 CSM 400 g/m 2 0.4 isotropic Vinylester<br />

CSM 0 4 4 CSM 400 g/m 2 0.4 isotropic Polyester<br />

800/100 90 5 5 CSM 100 g/m 2 0.1 isotropic Polyester<br />

Combimat 6 WR 50%/50% 800 g/m 2 0.8 0 Polyester<br />

800/100 90 6 7 CSM 100 g/m 2 0.1 isotropic Polyester<br />

Combimat 8 WR 50%/50% 800 g/m 2 0.8 90 Polyester<br />

CSM 0 7 9 CSM 400 g/m 2 0.4 isotropic Polyester<br />

90,+45 multiax 90 8 10 SF 400 g/m 2 0.4 0 Polyester<br />

800 g 11 SF 200 g/m 2 0.2 +45 Polyester<br />

12 SF 200 g/m 2 0.2 -45 Polyester<br />

90,+45 multiax 0 9 13 SF 400 g/m 2 0.4 90 Polyester<br />

800 g 14 SF 200 g/m 2 0.2 +45 Polyester<br />

15 SF 200 g/m 2 0.2 -45 Polyester<br />

multiax hybrid 90 10 16 CSM 100 g/m 2 0.1 isotropic Polyester<br />

combi 17 SF 50%Aramid50%Glass 300 g/m 2 0.3 +45 Polyester<br />

18 SF 50%Aramid50%Glass 300 g/m 2 0.3 -45 Polyester<br />

multiax hybrid 90 11 19 CSM 100 g/m 2 0.1 isotropic Polyester<br />

combi 20 SF 300 g/m 2 0.3 +45 Polyester<br />

21 SF Aramid 400 g/m 2 0.4 0 Polyester<br />

22 SF 300 g/m 2 0.3 -45 Polyester<br />

Twill 90 12 23 WR 70%weft 30%warp 450 g/m 2 0.45 0 Polyester<br />

Twill 0 13 24 WR 70%weft 30%warp 450 g/m 2 0.45 90 Polyester<br />

Surface Ply 0 14 25 WR 50/50 Polyester 450 g/m 2 0.45 0/90 Polyester<br />

DET NORSKE VERITAS AS