OS-C501

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Offshore Standard DNV-<strong>OS</strong>-<strong>C501</strong>, November 2013<br />

Sec.4 Materials - laminates – Page 71<br />

long test term curve. The characteristic long term test curve shall be based on the representative data's mean<br />

curve minus two standard deviations. Details to obtain such a curve are given in [3.11]. (It shall be assumed that<br />

the representative data are based on infinite measurements in [3.11.7], even if that was not the case in reality.)<br />

8.10 Use of manufacturers data or data from the literature as representative data<br />

8.10.1 There is a vast amount of data available, but unfortunately data are often not well documented and<br />

essential information tends to be missing.<br />

8.10.2 This section describes under which conditions such data may be used.<br />

8.10.3 It shall be documented that the data come from a reputable source. This can be done in the following<br />

way:<br />

— all data were taken from calibrated test equipment<br />

— data were witnessed by an independent third party or data were published and reviewed by at least two<br />

independent research teams.<br />

8.10.4 If these requirements are not met data can still be used as representative data, but all new materials data<br />

have to be confirmed against these data, even if the requirements in [8.6] do not require a confirmation.<br />

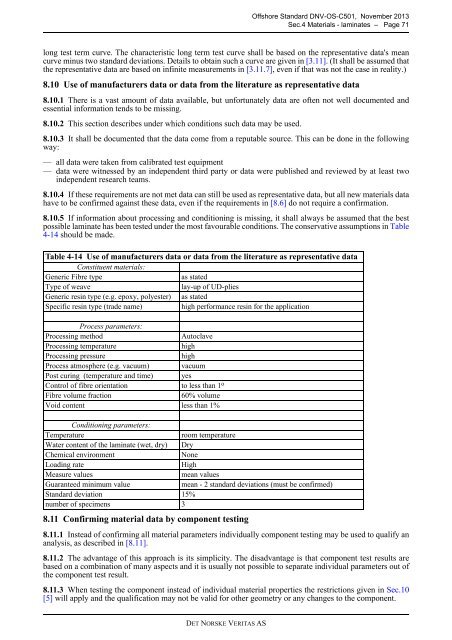

8.10.5 If information about processing and conditioning is missing, it shall always be assumed that the best<br />

possible laminate has been tested under the most favourable conditions. The conservative assumptions in Table<br />

4-14 should be made.<br />

Table 4-14 Use of manufacturers data or data from the literature as representative data<br />

Constituent materials:<br />

Generic Fibre type<br />

as stated<br />

Type of weave<br />

lay-up of UD-plies<br />

Generic resin type (e.g. epoxy, polyester) as stated<br />

Specific resin type (trade name)<br />

high performance resin for the application<br />

Process parameters:<br />

Processing method<br />

Autoclave<br />

Processing temperature<br />

high<br />

Processing pressure<br />

high<br />

Process atmosphere (e.g. vacuum) vacuum<br />

Post curing (temperature and time) yes<br />

Control of fibre orientation<br />

to less than 1 o<br />

Fibre volume fraction<br />

60% volume<br />

Void content less than 1%<br />

Conditioning parameters:<br />

Temperature<br />

room temperature<br />

Water content of the laminate (wet, dry) Dry<br />

Chemical environment<br />

None<br />

Loading rate<br />

High<br />

Measure values<br />

mean values<br />

Guaranteed minimum value<br />

mean - 2 standard deviations (must be confirmed)<br />

Standard deviation 15%<br />

number of specimens 3<br />

8.11 Confirming material data by component testing<br />

8.11.1 Instead of confirming all material parameters individually component testing may be used to qualify an<br />

analysis, as described in [8.11].<br />

8.11.2 The advantage of this approach is its simplicity. The disadvantage is that component test results are<br />

based on a combination of many aspects and it is usually not possible to separate individual parameters out of<br />

the component test result.<br />

8.11.3 When testing the component instead of individual material properties the restrictions given in Sec.10<br />

[5] will apply and the qualification may not be valid for other geometry or any changes to the component.<br />

DET NORSKE VERITAS AS