OS-C501

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Offshore Standard DNV-<strong>OS</strong>-<strong>C501</strong>, November 2013<br />

Sec.5 Materials – sandwich structures – Page 75<br />

1 General<br />

1.1 Introduction<br />

SECTION 5 MATERIALS – SANDWICH STRUCTURES<br />

1.1.1 This section describes the mechanical material properties needed for design. It describes how to obtain<br />

all strength properties used in the failure criteria and all elastic properties needed for stress calculations.<br />

1.1.2 A sandwich structure is considered here as a light weight core embedded between two faces (or skins).<br />

Faces are typically made of FRP laminates. The properties of laminates are described in Sec.4. This section<br />

concentrates on properties of cores and the core skin interface.<br />

1.1.3 All properties shall be obtained directly by measurements or shall be traced back to measurements. The<br />

qualification of material properties is described in this section. Under certain conditions, typical values from<br />

databases can be used. Strength and stiffness values should be documented as characteristic values.<br />

1.1.4 It is only necessary to obtain properties that are used in the design calculations and failure criteria.<br />

1.1.5 General aspects that were already described in Sec.4 are not repeated here but only referred to.<br />

1.2 Sandwich specification<br />

1.2.1 A sandwich structure is made of many constituent material arranged and produced in a specific way.<br />

Laminate, core materials and adhesives used in a sandwich component shall be clearly specified and all<br />

materials shall be traceable. Laminate specification shall be organised as described in Sec.4.<br />

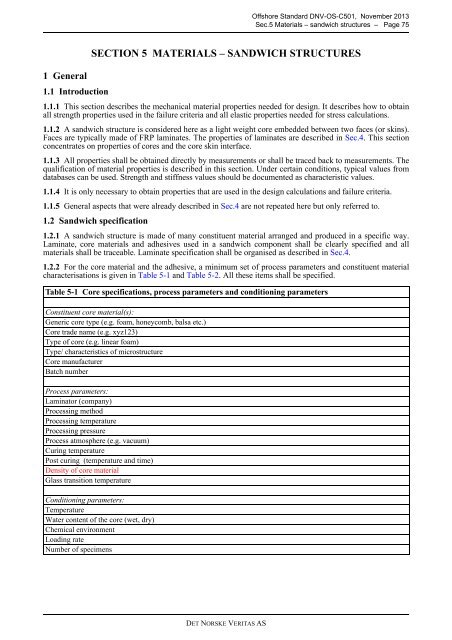

1.2.2 For the core material and the adhesive, a minimum set of process parameters and constituent material<br />

characterisations is given in Table 5-1 and Table 5-2. All these items shall be specified.<br />

Table 5-1 Core specifications, process parameters and conditioning parameters<br />

Constituent core material(s):<br />

Generic core type (e.g. foam, honeycomb, balsa etc.)<br />

Core trade name (e.g. xyz123)<br />

Type of core (e.g. linear foam)<br />

Type/ characteristics of microstructure<br />

Core manufacturer<br />

Batch number<br />

Process parameters:<br />

Laminator (company)<br />

Processing method<br />

Processing temperature<br />

Processing pressure<br />

Process atmosphere (e.g. vacuum)<br />

Curing temperature<br />

Post curing (temperature and time)<br />

Density of core material<br />

Glass transition temperature<br />

Conditioning parameters:<br />

Temperature<br />

Water content of the core (wet, dry)<br />

Chemical environment<br />

Loading rate<br />

Number of specimens<br />

DET NORSKE VERITAS AS