OS-C501

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Offshore Standard DNV-<strong>OS</strong>-<strong>C501</strong>, November 2013<br />

Sec.5 Materials – sandwich structures – Page 76<br />

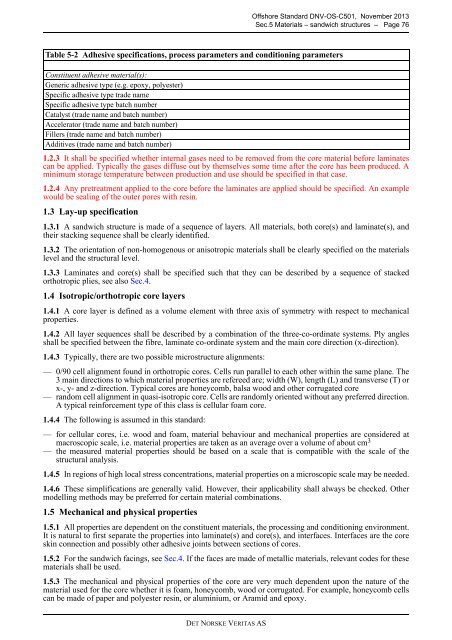

Table 5-2 Adhesive specifications, process parameters and conditioning parameters<br />

Constituent adhesive material(s):<br />

Generic adhesive type (e.g. epoxy, polyester)<br />

Specific adhesive type trade name<br />

Specific adhesive type batch number<br />

Catalyst (trade name and batch number)<br />

Accelerator (trade name and batch number)<br />

Fillers (trade name and batch number)<br />

Additives (trade name and batch number)<br />

1.2.3 It shall be specified whether internal gases need to be removed from the core material before laminates<br />

can be applied. Typically the gases diffuse out by themselves some time after the core has been produced. A<br />

minimum storage temperature between production and use should be specified in that case.<br />

1.2.4 Any pretreatment applied to the core before the laminates are applied should be specified. An example<br />

would be sealing of the outer pores with resin.<br />

1.3 Lay-up specification<br />

1.3.1 A sandwich structure is made of a sequence of layers. All materials, both core(s) and laminate(s), and<br />

their stacking sequence shall be clearly identified.<br />

1.3.2 The orientation of non-homogenous or anisotropic materials shall be clearly specified on the materials<br />

level and the structural level.<br />

1.3.3 Laminates and core(s) shall be specified such that they can be described by a sequence of stacked<br />

orthotropic plies, see also Sec.4.<br />

1.4 Isotropic/orthotropic core layers<br />

1.4.1 A core layer is defined as a volume element with three axis of symmetry with respect to mechanical<br />

properties.<br />

1.4.2 All layer sequences shall be described by a combination of the three-co-ordinate systems. Ply angles<br />

shall be specified between the fibre, laminate co-ordinate system and the main core direction (x-direction).<br />

1.4.3 Typically, there are two possible microstructure alignments:<br />

— 0/90 cell alignment found in orthotropic cores. Cells run parallel to each other within the same plane. The<br />

3 main directions to which material properties are refereed are; width (W), length (L) and transverse (T) or<br />

x-, y- and z-direction. Typical cores are honeycomb, balsa wood and other corrugated core<br />

— random cell alignment in quasi-isotropic core. Cells are randomly oriented without any preferred direction.<br />

A typical reinforcement type of this class is cellular foam core.<br />

1.4.4 The following is assumed in this standard:<br />

— for cellular cores, i.e. wood and foam, material behaviour and mechanical properties are considered at<br />

macroscopic scale, i.e. material properties are taken as an average over a volume of about cm 3<br />

— the measured material properties should be based on a scale that is compatible with the scale of the<br />

structural analysis.<br />

1.4.5 In regions of high local stress concentrations, material properties on a microscopic scale may be needed.<br />

1.4.6 These simplifications are generally valid. However, their applicability shall always be checked. Other<br />

modelling methods may be preferred for certain material combinations.<br />

1.5 Mechanical and physical properties<br />

1.5.1 All properties are dependent on the constituent materials, the processing and conditioning environment.<br />

It is natural to first separate the properties into laminate(s) and core(s), and interfaces. Interfaces are the core<br />

skin connection and possibly other adhesive joints between sections of cores.<br />

1.5.2 For the sandwich facings, see Sec.4. If the faces are made of metallic materials, relevant codes for these<br />

materials shall be used.<br />

1.5.3 The mechanical and physical properties of the core are very much dependent upon the nature of the<br />

material used for the core whether it is foam, honeycomb, wood or corrugated. For example, honeycomb cells<br />

can be made of paper and polyester resin, or aluminium, or Aramid and epoxy.<br />

DET NORSKE VERITAS AS