You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

NOTE2.--Platinum RTDs meeting DIN Standard 43760 (Class A) or equal are recommended for this<br />

purpose. The RTD shall be calibrated as an integral unit with its respective meter or electronic circuitry.<br />

6.1.2.3 Reference Temperature Sensing Device--A thermistor, RTD, or<br />

thermocouple as described in sections 9.1.1.2.1, 9.1.1.2.2, or 9.1.1.2.3 shall be used.<br />

6.1.3 Loading device--The loading device shall apply a sinusoidal oscillatory load to<br />

the specimen at a frequency of 10.0 + 0.1 rad/s. If frequencies other than 10 rad/s are used,<br />

the frequency shall be accurate to 1%. The loading device shall be capable of providing<br />

either a stress-controlled or strain-controlled load. If the load is strain controlled, the loading<br />

device shall apply a cyclic torque sufficient to cause an angular rotational strain accurate to<br />

within 100 #rad of the strain specified. If the load is stress controlled, the loading device<br />

shall apply a cyclic torque accurate to within 10 mN.m of the torque specified. Total system<br />

compliance at 100 N.m torque shall be < 2 mrad/N.m.<br />

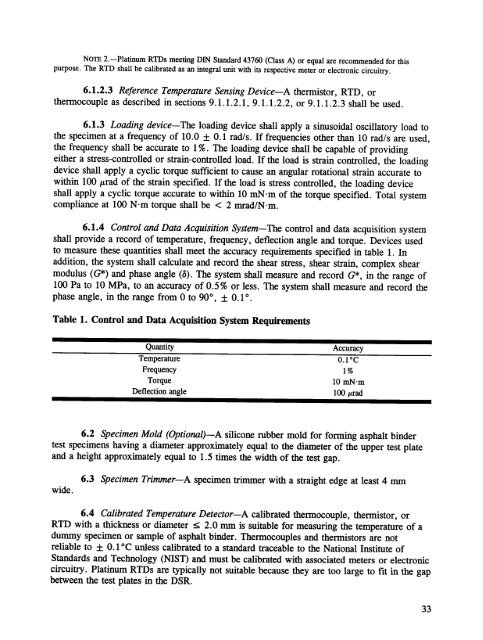

6.1.4 Control and Data Acquisition System--The control and data acquisition system<br />

shall provide a record of temperature, frequency, deflection angle and torque. Devices used<br />

to measure these quantities shall meet the accuracy requirements specified in table 1. In<br />

addition, the system shall calculate and record the shear stress, shear strain, complex shear<br />

modulus (G*) and phase angle (iS).The system shall measure and record G*, in the range of<br />

100 Pa to 10 MPa, to an accuracy of 0.5% or less. The system shall measure and record the<br />

phase angle, in the range from 0 to 90 °, + 0.1 °<br />

Table 1. Control and Data Acquisition<br />

System Requirements<br />

Quantity<br />

Accuracy<br />

Temperature 0.1 °C<br />

Frequency 1%<br />

Torque<br />

Deflection angle<br />

10 mN.m<br />

100 #rad<br />

6.2 Specimen Mold (Optional)--A silicone rubber mold for forming asphalt binder<br />

test specimens having a diameter approximately equal to the diameter of the upper test plate<br />

and a height approximately equal to 1.5 times the width of the test gap.<br />

wide.<br />

6.3 Specimen Trimmer--A specimen trimmer with a straight edge at least 4 mm<br />

6.4 Calibrated Temperature Detector--A calibrated thermocouple, thermistor, or<br />

RTD with a thickness or diameter < 2.0 mm is suitable for measuring the temperature of a<br />

dummy specimen or sample of asphalt binder. Thermocouples and thermistors are not<br />

reliable to -1-0.1 °C unless calibrated to a standard traceable to the National Institute of<br />

Standards and Technology (NIST) and must be calibrated with associated meters or electronic<br />

circuitry. Platinum RTDs are typically not suitable because they are too large to fit in the gap<br />

between the test plates in the DSR.<br />

33