European Bio-Energy Projects

European Bio-Energy Projects

European Bio-Energy Projects

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

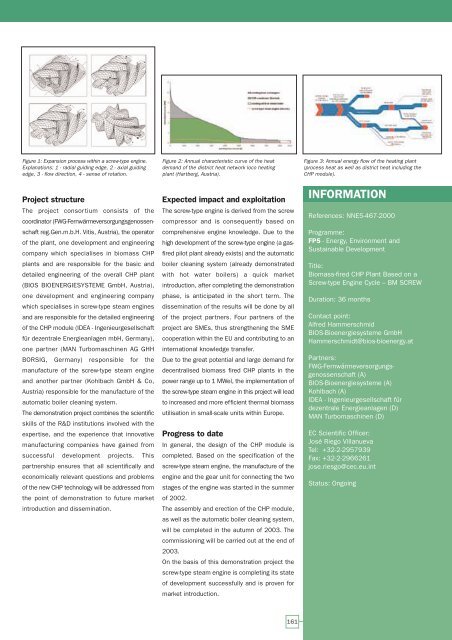

Figure 1: Expansion process within a screw-type engine.<br />

Explanations: 1 - radial guiding edge, 2 - axial guiding<br />

edge, 3 - flow direction, 4 - sense of rotation.<br />

Project structure<br />

The project consortium consists of the<br />

coordinator (FWG-Fernwärmeversorgungsgenossenschaft<br />

reg.Gen.m.b.H. Vitis, Austria), the operator<br />

of the plant, one development and engineering<br />

company which specialises in biomass CHP<br />

plants and are responsible for the basic and<br />

detailed engineering of the overall CHP plant<br />

(BIOS BIOENERGIESYSTEME GmbH, Austria),<br />

one development and engineering company<br />

which specialises in screw-type steam engines<br />

and are responsible for the detailed engineering<br />

of the CHP module (IDEA - Ingenieurgesellschaft<br />

für dezentrale Energieanlagen mbH, Germany),<br />

one partner (MAN Turbomaschinen AG GHH<br />

BORSIG, Germany) responsible for the<br />

manufacture of the screw-type steam engine<br />

and another partner (Kohlbach GmbH & Co,<br />

Austria) responsible for the manufacture of the<br />

automatic boiler cleaning system.<br />

The demonstration project combines the scientific<br />

skills of the R&D institutions involved with the<br />

expertise, and the experience that innovative<br />

manufacturing companies have gained from<br />

successful development projects. This<br />

partnership ensures that all scientifically and<br />

economically relevant questions and problems<br />

of the new CHP technology will be addressed from<br />

the point of demonstration to future market<br />

introduction and dissemination.<br />

Figure 2: Annual characteristic curve of the heat<br />

demand of the district heat network loco heating<br />

plant (Hartberg, Austria).<br />

Expected impact and exploitation<br />

The screw-type engine is derived from the screw<br />

compressor and is consequently based on<br />

comprehensive engine knowledge. Due to the<br />

high development of the screw-type engine (a gasfired<br />

pilot plant already exists) and the automatic<br />

boiler cleaning system (already demonstrated<br />

with hot water boilers) a quick market<br />

introduction, after completing the demonstration<br />

phase, is anticipated in the short term. The<br />

dissemination of the results will be done by all<br />

of the project partners. Four partners of the<br />

project are SMEs, thus strengthening the SME<br />

cooperation within the EU and contributing to an<br />

international knowledge transfer.<br />

Due to the great potential and large demand for<br />

decentralised biomass fired CHP plants in the<br />

power range up to 1 MWel, the implementation of<br />

the screw-type steam engine in this project will lead<br />

to increased and more efficient thermal biomass<br />

utilisation in small-scale units within Europe.<br />

Progress to date<br />

In general, the design of the CHP module is<br />

completed. Based on the specification of the<br />

screw-type steam engine, the manufacture of the<br />

engine and the gear unit for connecting the two<br />

stages of the engine was started in the summer<br />

of 2002.<br />

The assembly and erection of the CHP module,<br />

as well as the automatic boiler cleaning system,<br />

will be completed in the autumn of 2003. The<br />

commissioning will be carried out at the end of<br />

2003.<br />

On the basis of this demonstration project the<br />

screw-type steam engine is completing its state<br />

of development successfully and is proven for<br />

market introduction.<br />

161<br />

Figure 3: Annual energy flow of the heating plant<br />

(process heat as well as district heat including the<br />

CHP module).<br />

INFORMATION<br />

References: NNE5-467-2000<br />

Programme:<br />

FP5 - <strong>Energy</strong>, Environment and<br />

Sustainable Development<br />

Title:<br />

<strong>Bio</strong>mass-fired CHP Plant Based on a<br />

Screw-type Engine Cycle – BM SCREW<br />

Duration: 36 months<br />

Contact point:<br />

Alfred Hammerschmid<br />

BIOS-<strong>Bio</strong>energiesysteme GmbH<br />

Hammerschmidt@bios-bioenergy.at<br />

Partners:<br />

FWG-Fernwärmeversorgungsgenossenschaft<br />

(A)<br />

BIOS-<strong>Bio</strong>energiesysteme (A)<br />

Kohlbach (A)<br />

IDEA - Ingenieurgesellschaft für<br />

dezentrale Energieanlagen (D)<br />

MAN Turbomaschinen (D)<br />

EC Scientific Officer:<br />

José Riego Villanueva<br />

Tel: +32-2-2957939<br />

Fax: +32-2-2966261<br />

jose.riesgo@cec.eu.int<br />

Status: Ongoing