European Bio-Energy Projects

European Bio-Energy Projects

European Bio-Energy Projects

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

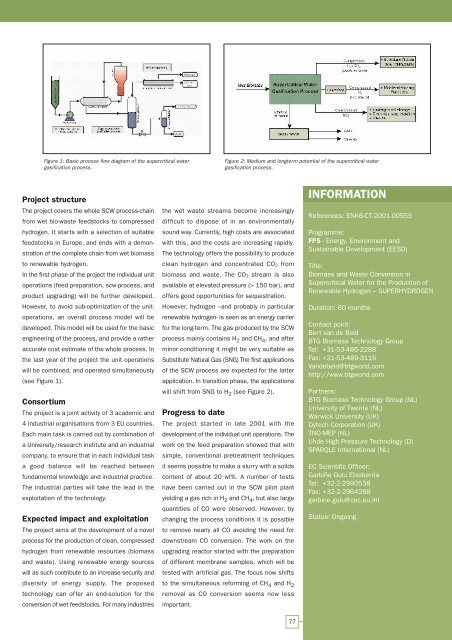

Figure 1: Basic process flow diagram of the supercritical water<br />

gasification process.<br />

Project structure<br />

The project covers the whole SCW process-chain<br />

from wet bio-waste feedstocks to compressed<br />

hydrogen. It starts with a selection of suitable<br />

feedstocks in Europe, and ends with a demonstration<br />

of the complete chain from wet biomass<br />

to renewable hydrogen.<br />

In the first phase of the project the individual unit<br />

operations (feed preparation, scw-process, and<br />

product upgrading) will be further developed.<br />

However, to avoid sub-optimization of the unitoperations,<br />

an overall process model will be<br />

developed. This model will be used for the basic<br />

engineering of the process, and provide a rather<br />

accurate cost estimate of the whole process. In<br />

the last year of the project the unit operations<br />

will be combined, and operated simultaneously<br />

(see Figure 1).<br />

Consortium<br />

The project is a joint activity of 3 academic and<br />

4 industrial organisations from 3 EU countries.<br />

Each main task is carried out by combination of<br />

a University/research institute and an industrial<br />

company, to ensure that in each individual task<br />

a good balance will be reached between<br />

fundamental knowledge and industrial practice.<br />

The industrial parties will take the lead in the<br />

exploitation of the technology.<br />

Expected impact and exploitation<br />

The project aims at the development of a novel<br />

process for the production of clean, compressed<br />

hydrogen from renewable resources (biomass<br />

and waste). Using renewable energy sources<br />

will as such contribute to an increase security and<br />

diversity of energy supply. The proposed<br />

technology can offer an end-solution for the<br />

conversion of wet feedstocks. For many industries<br />

the wet waste streams become increasingly<br />

difficult to dispose of in an environmentally<br />

sound way. Currently, high costs are associated<br />

with this, and the costs are increasing rapidly.<br />

The technology offers the possibility to produce<br />

clean hydrogen and concentrated CO2 from<br />

biomass and waste. The CO2 stream is also<br />

available at elevated pressure (> 150 bar), and<br />

offers good opportunities for sequestration.<br />

However, hydrogen –and probably in particular<br />

renewable hydrogen- is seen as an energy carrier<br />

for the long-term. The gas produced by the SCW<br />

process mainly contains H2 and CH4 , and after<br />

minor conditioning it might be very suitable as<br />

Substitute Natural Gas (SNG) The first applications<br />

of the SCW process are expected for the latter<br />

application. In transition phase, the applications<br />

will shift from SNG to H2 (see Figure 2).<br />

Progress to date<br />

Figure 2: Medium and longterm potential of the supercritical water<br />

gasification process.<br />

The project started in late 2001 with the<br />

development of the individual unit operations. The<br />

work on the feed preparation showed that with<br />

simple, conventional pretreatment techniques<br />

it seems possible to make a slurry with a solids<br />

content of about 20 wt%. A number of tests<br />

have been carried out in the SCW pilot plant<br />

yielding a gas rich in H2 and CH4 , but also large<br />

quantities of CO were observed. However, by<br />

changing the process conditions it is possible<br />

to remove nearly all CO avoiding the need for<br />

downstream CO conversion. The work on the<br />

upgrading reactor started with the preparation<br />

of different membrane samples, which will be<br />

tested with artificial gas. The focus now shifts<br />

to the simultaneous reforming of CH4 and H2 removal as CO conversion seems now less<br />

important.<br />

77<br />

INFORMATION<br />

References: ENK6-CT-2001-00555<br />

Programme:<br />

FP5 - <strong>Energy</strong>, Environment and<br />

Sustainable Development (EESD)<br />

Title:<br />

<strong>Bio</strong>mass and Waste Conversion in<br />

Supercritical Water for the Production of<br />

Renewable Hydrogen – SUPERHYDROGEN<br />

Duration: 60 months<br />

Contact point:<br />

Bert van de Beld<br />

BTG <strong>Bio</strong>mass Technology Group<br />

Tel: +31-53-486-2288<br />

Fax: +31-53-489-3116<br />

Vandebeld@btgworld.com<br />

http://www.btgworld.com<br />

Partners:<br />

BTG <strong>Bio</strong>mass Technology Group (NL)<br />

University of Twente (NL)<br />

Warwick University (UK)<br />

Dytech Corporation (UK)<br />

TNO-MEP (NL)<br />

Uhde High Pressure Technology (D)<br />

SPARQLE International (NL)<br />

EC Scientific Officer:<br />

Garbiñe Guiu Etxeberria<br />

Tel: +32-2-2990538<br />

Fax: +32-2-2964288<br />

garbine.guiu@cec.eu.int<br />

Status: Ongoing