European Bio-Energy Projects

European Bio-Energy Projects

European Bio-Energy Projects

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

NOVEL CHP process.<br />

Results<br />

The development of the catalytic filter included<br />

testing and optimisation of catalyst formulations<br />

with simulated and real gases. Novel modified<br />

nickel-activated alumina filter substrates were<br />

developed, prepared and screened. Improvement<br />

in the resistance to deactivation by sulphur<br />

compounds in biomass gasification was one of the<br />

main objectives and achievements of the work.<br />

Valuable information about catalyst improvement<br />

techniques was obtained. The catalytic filter was<br />

also tested with real gases and promising results<br />

were achieved. Preparation procedures for largescale<br />

candle filters were also developed.<br />

The long-term testing of the nickel monolith was<br />

performed with a slipstream apparatus that was<br />

connected to a CFB gasifier. The total test length<br />

was 2 267 h. The main conclusions of the long-term<br />

test were: 1) the nickel monolith catalyst activity<br />

remained at a high level during the test, 2) it is<br />

probable that the catalyst will remain active for<br />

longer periods of time, 3) tar conversion after the<br />

test was 92% and ammonia conversion 70 % at the<br />

900 °C operation temperature, 4) fouling or clogging<br />

of the monolith by carbon did not occur.<br />

The technical feasibility of the monolith-based<br />

concept was demonstrated by performing a pilotscale<br />

test run with a process consisting of a<br />

NOVEL fixed bed gasifier, a catalytic reformer<br />

followed by a filter and gas scrubber/cooler.<br />

The gas produced had very low tar (< 100<br />

mg/Nm3), ammonia (< 50 ppm) and particle<br />

(< 5 mg/ Nm3) contents and it can be considered<br />

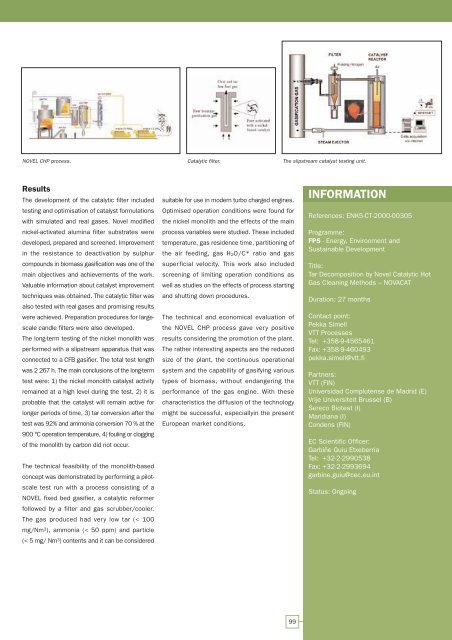

Catalytic filter. The slipstream catalyst testing unit.<br />

suitable for use in modern turbo charged engines.<br />

Optimised operation conditions were found for<br />

the nickel monolith and the effects of the main<br />

process variables were studied. These included<br />

temperature, gas residence time, partitioning of<br />

the air feeding, gas H2O/C* ratio and gas<br />

superficial velocity. This work also included<br />

screening of limiting operation conditions as<br />

well as studies on the effects of process starting<br />

and shutting down procedures.<br />

The technical and economical evaluation of<br />

the NOVEL CHP process gave very positive<br />

results considering the promotion of the plant.<br />

The rather interesting aspects are the reduced<br />

size of the plant, the continuous operational<br />

system and the capability of gasifying various<br />

types of biomass, without endangering the<br />

performance of the gas engine. With these<br />

characteristics the diffusion of the technology<br />

might be successful, especiallyin the present<br />

<strong>European</strong> market conditions.<br />

99<br />

INFORMATION<br />

References: ENK5-CT-2000-00305<br />

Programme:<br />

FP5 - <strong>Energy</strong>, Environment and<br />

Sustainable Development<br />

Title:<br />

Tar Decomposition by Novel Catalytic Hot<br />

Gas Cleaning Methods – NOVACAT<br />

Duration: 27 months<br />

Contact point:<br />

Pekka Simell<br />

VTT Processes<br />

Tel: +358-9-4565461<br />

Fax: +358-9-460493<br />

pekka.simell@vtt.fi<br />

Partners:<br />

VTT (FIN)<br />

Universidad Complutense de Madrid (E)<br />

Vrije Universiteit Brussel (B)<br />

Sereco <strong>Bio</strong>test (I)<br />

Maridiana (I)<br />

Condens (FIN)<br />

EC Scientific Officer:<br />

Garbiñe Guiu Etxeberria<br />

Tel: +32-2-2990538<br />

Fax: +32-2-2993694<br />

garbine.guiu@cec.eu.int<br />

Status: Ongoing