European Bio-Energy Projects

European Bio-Energy Projects

European Bio-Energy Projects

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Expected impact and exploitation<br />

In the first place, the Guideline will allow<br />

companies, institutions and universities that<br />

develop gasification technology to compare<br />

tar concentrations. Secondly, it will allow<br />

manufacturers of gasifiers, gas cleaning systems<br />

and engine or turbine generator sets to convince<br />

potential end users of the technical performance<br />

of the sub-systems, and to define tolerances from<br />

which guarantees on performance, system lifetime<br />

etc. can be derived. These guarantees decrease<br />

the non-technical risks of implementation of<br />

biomass gasification based systems.<br />

The Guideline will be transformed into a CEN<br />

Standard to widen its international acceptance<br />

and application. To this purpose, CEN Task Force<br />

143 “Measurement of Organic Contaminants<br />

(tars) in <strong>Bio</strong>mass Producer Gases” has been<br />

installed.<br />

Results<br />

Figure 1: Project management structure.<br />

The main result of this project is a guideline for<br />

the sampling and analysis of tars and particles in<br />

biomass gasification producer gases. The<br />

measurement principle of the Guideline is based<br />

on discontinuous sampling and it is set-up in<br />

such a way that particles can also be measured<br />

quantitatively. The tar and particle sampling<br />

system consists of a heated probe, a heated<br />

particle filter, a condenser and a series of impinger<br />

bottles containing isopropanol to dissolve the<br />

tars. The solvent containing bottles are placed in<br />

a warm (bottles 1-4) and a cold bath (bottles 5 and<br />

6) so that the sampled gas is cooled in two steps,<br />

first to 20°C and finally to -20°. The sampling train<br />

is shown schematically in Figure 2. The postsampling<br />

involves Soxhlet extraction of the tars on<br />

the particle filter and the collection of all tars in<br />

one bulk solution. Finally, the analysis comprises<br />

the determination of the gravimetric tar mass<br />

from the bulk solution and the determination of<br />

the concentration of individual tar compounds.<br />

The Guideline has also achieved the following<br />

results:<br />

• It can be used for both raw and clean producer<br />

gases of all commonly applied biomass gasifiers<br />

• It has been disseminated to, and gained<br />

acceptance among, major <strong>European</strong> and North<br />

American parties that develop, commercialise<br />

and advise on biomass gasification technology<br />

• It has entered the procedure to become a<br />

<strong>European</strong> standard.<br />

The full version of the Guideline can be downloaded<br />

from the website.<br />

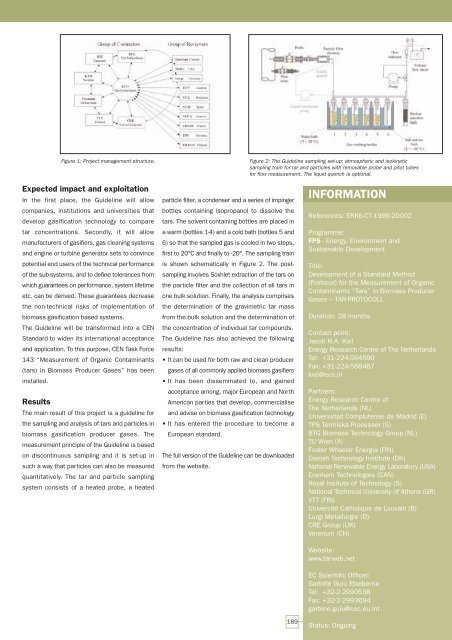

Figure 2: The Guideline sampling set-up: atmospheric and isokinetic<br />

sampling train for tar and particles with removable probe and pitot tubes<br />

for flow measurement. The liquid quench is optional.<br />

189<br />

INFORMATION<br />

References: ERK6-CT-1999-20002<br />

Programme:<br />

FP5 - <strong>Energy</strong>, Environment and<br />

Sustainable Development<br />

Title:<br />

Development of a Standard Method<br />

(Protocol) for the Measurement of Organic<br />

Contaminants “Tars” in <strong>Bio</strong>mass Producer<br />

Gases – TAR-PROTOCOLL<br />

Duration: 28 months<br />

Contact point:<br />

Jacob H.A. Kiel<br />

<strong>Energy</strong> Research Centre of The Netherlands<br />

Tel: +31-224-564590<br />

Fax: +31-224-568487<br />

kiel@ecn.nl<br />

Partners:<br />

<strong>Energy</strong> Research Centre of<br />

The Netherlands (NL)<br />

Universidad Complutense de Madrid (E)<br />

TPS Termiska Processer (S)<br />

BTG <strong>Bio</strong>mass Technology Group (NL)<br />

TU Wien (A)<br />

Foster Wheeler Energia (FIN)<br />

Danish Technology Institute (DK)<br />

National Renewable <strong>Energy</strong> Laboratory (USA)<br />

Enerkem Technologies (CAN)<br />

Royal Insitute of Technology (S)<br />

National Technical University of Athens (GR)<br />

VTT (FIN)<br />

Université Catholique de Louvain (B)<br />

Lurgi Metallurgie (D)<br />

CRE Group (UK)<br />

Verenum (CH)<br />

Website:<br />

www.tarweb.net<br />

EC Scientific Officer:<br />

Garbiñe Guiu Etxeberria<br />

Tel: +32-2-2990538<br />

Fax: +32-2-2993694<br />

garbine.guiu@cec.eu.int<br />

Status: Ongoing