Journal of Film Preservation - FIAF

Journal of Film Preservation - FIAF

Journal of Film Preservation - FIAF

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Los pocos datos encontrados en la<br />

bibliografía apoyan la hipótesis que<br />

las películas son particularmente<br />

sensibles a la contaminación por<br />

bacterias y hongos, sobre todo cuando<br />

estos materiales se conservan en<br />

condiciones que favorecen la<br />

proliferación microbiana.<br />

Las condiciones de<br />

preservación adecuadas y<br />

exámenes periódicos<br />

preventivos de los materiales<br />

de colección reducirán los<br />

riesgos de deterioro<br />

microbiano de las películas<br />

cinematográficas, concluyen<br />

los autores.<br />

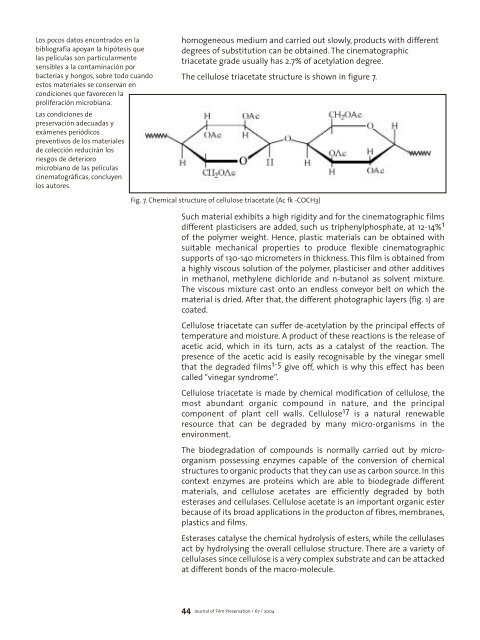

homogeneous medium and carried out slowly, products with different<br />

degrees <strong>of</strong> substitution can be obtained. The cinematographic<br />

triacetate grade usually has 2.7% <strong>of</strong> acetylation degree.<br />

The cellulose triacetate structure is shown in figure 7.<br />

Fig. 7. Chemical structure <strong>of</strong> cellulose triacetate (Ac ∫ -COCH3)<br />

Such material exhibits a high rigidity and for the cinematographic films<br />

different plasticisers are added, such us triphenylphosphate, at 12-14% 1<br />

<strong>of</strong> the polymer weight. Hence, plastic materials can be obtained with<br />

suitable mechanical properties to produce flexible cinematographic<br />

supports <strong>of</strong> 130-140 micrometers in thickness. This film is obtained from<br />

a highly viscous solution <strong>of</strong> the polymer, plasticiser and other additives<br />

in methanol, methylene dichloride and n-butanol as solvent mixture.<br />

The viscous mixture cast onto an endless conveyor belt on which the<br />

material is dried. After that, the different photographic layers (fig. 1) are<br />

coated.<br />

Cellulose triacetate can suffer de-acetylation by the principal effects <strong>of</strong><br />

temperature and moisture. A product <strong>of</strong> these reactions is the release <strong>of</strong><br />

acetic acid, which in its turn, acts as a catalyst <strong>of</strong> the reaction. The<br />

presence <strong>of</strong> the acetic acid is easily recognisable by the vinegar smell<br />

that the degraded films1-5 give <strong>of</strong>f, which is why this effect has been<br />

called “vinegar syndrome”.<br />

Cellulose triacetate is made by chemical modification <strong>of</strong> cellulose, the<br />

most abundant organic compound in nature, and the principal<br />

component <strong>of</strong> plant cell walls. Cellulose17 is a natural renewable<br />

resource that can be degraded by many micro-organisms in the<br />

environment.<br />

The biodegradation <strong>of</strong> compounds is normally carried out by microorganism<br />

possessing enzymes capable <strong>of</strong> the conversion <strong>of</strong> chemical<br />

structures to organic products that they can use as carbon source. In this<br />

context enzymes are proteins which are able to biodegrade different<br />

materials, and cellulose acetates are efficiently degraded by both<br />

esterases and cellulases. Cellulose acetate is an important organic ester<br />

because <strong>of</strong> its broad applications in the producton <strong>of</strong> fibres, membranes,<br />

plastics and films.<br />

Esterases catalyse the chemical hydrolysis <strong>of</strong> esters, while the cellulases<br />

act by hydrolysing the overall cellulose structure. There are a variety <strong>of</strong><br />

cellulases since cellulose is a very complex substrate and can be attacked<br />

at different bonds <strong>of</strong> the macro-molecule.<br />

44 <strong>Journal</strong> <strong>of</strong> <strong>Film</strong> <strong>Preservation</strong> / 67 / 2004