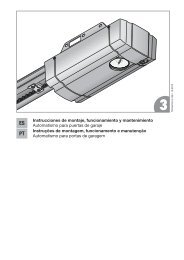

Automatismo para puerta corredera LineaMatic - Hörmann

Automatismo para puerta corredera LineaMatic - Hörmann

Automatismo para puerta corredera LineaMatic - Hörmann

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ENGLISH<br />

7.2 Programming the hand transmitter buttons on<br />

an integral radio receiver<br />

1. Briefly press print button P once (for channel 1 = impulse<br />

command) or twice (for channel 2 = partial opening<br />

command).<br />

Pressing circuit board button P again will immediately<br />

end radio programming.<br />

Depending on the channel being programmed, the red<br />

LED will flash 1x (for channel 1) or 2x (for channel 2).<br />

During this time, a hand transmitter button can be<br />

programmed for the desired function.<br />

2. Press the hand transmitter button to be programmed<br />

until the red LED on the print flashes rapidly.<br />

The code for this hand transmitter button is now stored in<br />

the integral radio receiver (see Figure 9).<br />

7.3 Deleting all data of an integral radio receiver<br />

ff<br />

Press print button P and keep it pressed.<br />

The red LED flashes slowly, signalling the readiness for<br />

deletion. The flashing rhythm becomes more rapid.<br />

Afterwards, the programmed radio codes of all hand<br />

transmitters are deleted.<br />

7.3.1 Connecting an external radio receiver*<br />

(*Accessory, not included as standard equipment!)<br />

Instead of an integral radio receiver, an external radio receiver<br />

can be used for the impulse or partial opening functions to<br />

control the sliding gate operator. Insert the plug of the receiver<br />

in the corresponding slot (see Figure 4.1). To avoid double<br />

assignments, delete the data of the integral radio receiver<br />

when using an external radio receiver (see Deleting all data of<br />

an integral radio receiver, page 31).<br />

8<br />

Restoring the Factory Setting of the<br />

Sliding Gate Operator<br />

Resetting the control (learned end-of-travel positions,<br />

forces):<br />

1. Set DIL switch 2 to ON.<br />

2. Immediately press print button P briefly.<br />

3. When the red LED flashes rapidly, DIL switch 2 must be<br />

quickly set to OFF.<br />

The control system has now been reset to the factory<br />

setting.<br />

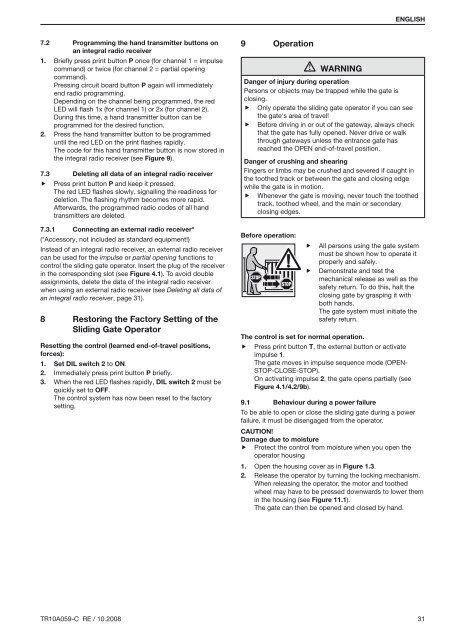

9<br />

Operation<br />

WARNING<br />

Danger of injury during operation<br />

Persons or objects may be trapped while the gate is<br />

closing.<br />

ff Only operate the sliding gate operator if you can see<br />

the gate's area of travel!<br />

ff Before driving in or out of the gateway, always check<br />

that the gate has fully opened. Never drive or walk<br />

through gateways unless the entrance gate has<br />

reached the OPEN end-of-travel position.<br />

Danger of crushing and shearing<br />

Fingers or limbs may be crushed and severed if caught in<br />

the toothed track or between the gate and closing edge<br />

while the gate is in motion.<br />

ff Whenever the gate is moving, never touch the toothed<br />

track, toothed wheel, and the main or secondary<br />

closing edges.<br />

Before operation:<br />

ff All persons using the gate system<br />

must be shown how to operate it<br />

properly and safely.<br />

ff Demonstrate and test the<br />

mechanical release as well as the<br />

safety return. To do this, halt the<br />

closing gate by grasping it with<br />

both hands.<br />

The gate system must initiate the<br />

safety return.<br />

The control is set for normal operation.<br />

ff<br />

Press print button T, the external button or activate<br />

impulse 1.<br />

The gate moves in impulse sequence mode (OPEN-<br />

STOP-CLOSE-STOP).<br />

On activating impulse 2, the gate opens partially (see<br />

Figure 4.1/4.2/9b).<br />

9.1 Behaviour during a power failure<br />

To be able to open or close the sliding gate during a power<br />

failure, it must be disengaged from the operator.<br />

Caution!<br />

Damage due to moisture<br />

ff Protect the control from moisture when you open the<br />

operator housing<br />

1. Open the housing cover as in Figure 1.3.<br />

2. Release the operator by turning the locking mechanism.<br />

When releasing the operator, the motor and toothed<br />

wheel may have to be pressed downwards to lower them<br />

in the housing (see Figure 11.1).<br />

The gate can then be opened and closed by hand.<br />

TR10A059-C RE / 10.2008 31