Environmental Statement - Maersk Oil

Environmental Statement - Maersk Oil

Environmental Statement - Maersk Oil

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

2.5.4. METERING<br />

2 ‐ 18<br />

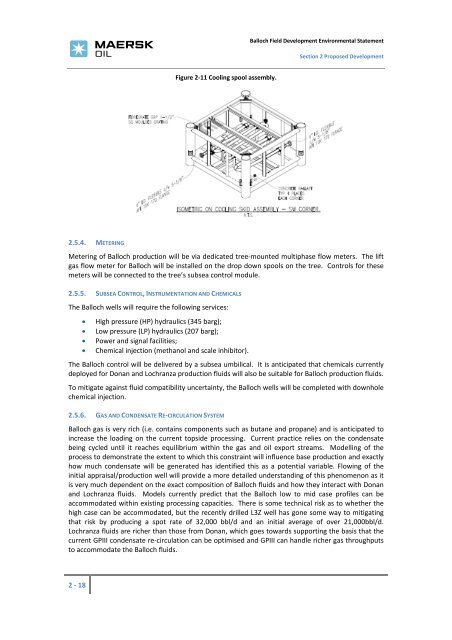

Figure 2‐11 Cooling spool assembly.<br />

Balloch Field Development <strong>Environmental</strong> <strong>Statement</strong><br />

Section 2 Proposed Development<br />

Metering of Balloch production will be via dedicated tree‐mounted multiphase flow meters. The lift<br />

gas flow meter for Balloch will be installed on the drop down spools on the tree. Controls for these<br />

meters will be connected to the tree’s subsea control module.<br />

2.5.5. SUBSEA CONTROL, INSTRUMENTATION AND CHEMICALS<br />

The Balloch wells will require the following services:<br />

High pressure (HP) hydraulics (345 barg);<br />

Low pressure (LP) hydraulics (207 barg);<br />

Power and signal facilities;<br />

Chemical injection (methanol and scale inhibitor).<br />

The Balloch control will be delivered by a subsea umbilical. It is anticipated that chemicals currently<br />

deployed for Donan and Lochranza production fluids will also be suitable for Balloch production fluids.<br />

To mitigate against fluid compatibility uncertainty, the Balloch wells will be completed with downhole<br />

chemical injection.<br />

2.5.6. GAS AND CONDENSATE RE‐CIRCULATION SYSTEM<br />

Balloch gas is very rich (i.e. contains components such as butane and propane) and is anticipated to<br />

increase the loading on the current topside processing. Current practice relies on the condensate<br />

being cycled until it reaches equilibrium within the gas and oil export streams. Modelling of the<br />

process to demonstrate the extent to which this constraint will influence base production and exactly<br />

how much condensate will be generated has identified this as a potential variable. Flowing of the<br />

initial appraisal/production well will provide a more detailed understanding of this phenomenon as it<br />

is very much dependent on the exact composition of Balloch fluids and how they interact with Donan<br />

and Lochranza fluids. Models currently predict that the Balloch low to mid case profiles can be<br />

accommodated within existing processing capacities. There is some technical risk as to whether the<br />

high case can be accommodated, but the recently drilled L3Z well has gone some way to mitigating<br />

that risk by producing a spot rate of 32,000 bbl/d and an initial average of over 21,000bbl/d.<br />

Lochranza fluids are richer than those from Donan, which goes towards supporting the basis that the<br />

current GPIII condensate re‐circulation can be optimised and GPIII can handle richer gas throughputs<br />

to accommodate the Balloch fluids.