CHEMICAL VAPOR DEPOSITION OF THIN FILM MATERIALS FOR ...

CHEMICAL VAPOR DEPOSITION OF THIN FILM MATERIALS FOR ...

CHEMICAL VAPOR DEPOSITION OF THIN FILM MATERIALS FOR ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

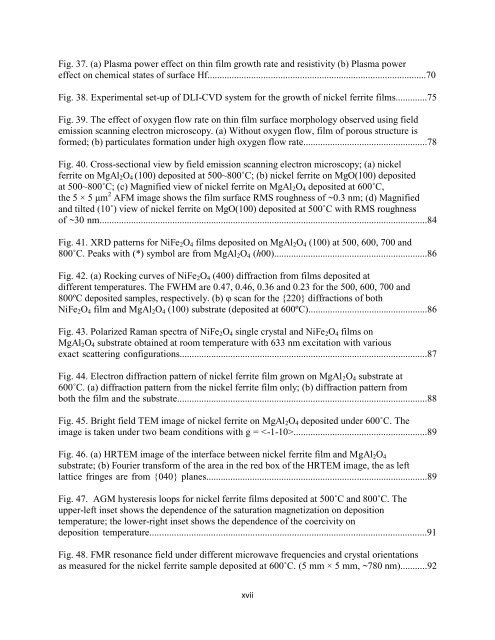

Fig. 37. (a) Plasma power effect on thin film growth rate and resistivity (b) Plasma power<br />

effect on chemical states of surface Hf..........................................................................................70<br />

Fig. 38. Experimental set-up of DLI-CVD system for the growth of nickel ferrite films.............75<br />

Fig. 39. The effect of oxygen flow rate on thin film surface morphology observed using field<br />

emission scanning electron microscopy. (a) Without oxygen flow, film of porous structure is<br />

formed; (b) particulates formation under high oxygen flow rate...................................................78<br />

Fig. 40. Cross-sectional view by field emission scanning electron microscopy; (a) nickel<br />

ferrite on MgAl2O4 (100) deposited at 500~800˚C; (b) nickel ferrite on MgO(100) deposited<br />

at 500~800˚C; (c) Magnified view of nickel ferrite on MgAl2O4 deposited at 600˚C,<br />

the 5 × 5 μm 2 AFM image shows the film surface RMS roughness of ~0.3 nm; (d) Magnified<br />

and tilted (10˚) view of nickel ferrite on MgO(100) deposited at 500˚C with RMS roughness<br />

of ~30 nm.......................................................................................................................................84<br />

Fig. 41. XRD patterns for NiFe2O4 films deposited on MgAl2O4 (100) at 500, 600, 700 and<br />

800˚C. Peaks with (*) symbol are from MgAl2O4 (h00)...............................................................86<br />

Fig. 42. (a) Rocking curves of NiFe2O4 (400) diffraction from films deposited at<br />

different temperatures. The FWHM are 0.47, 0.46, 0.36 and 0.23 for the 500, 600, 700 and<br />

800ºC deposited samples, respectively. (b) φ scan for the {220} diffractions of both<br />

NiFe2O4 film and MgAl2O4 (100) substrate (deposited at 600ºC).................................................86<br />

Fig. 43. Polarized Raman spectra of NiFe2O4 single crystal and NiFe2O4 films on<br />

MgAl2O4 substrate obtained at room temperature with 633 nm excitation with various<br />

exact scattering configurations......................................................................................................87<br />

Fig. 44. Electron diffraction pattern of nickel ferrite film grown on MgAl2O4 substrate at<br />

600˚C. (a) diffraction pattern from the nickel ferrite film only; (b) diffraction pattern from<br />

both the film and the substrate.......................................................................................................88<br />

Fig. 45. Bright field TEM image of nickel ferrite on MgAl2O4 deposited under 600˚C. The<br />

image is taken under two beam conditions with g = .......................................................89<br />

Fig. 46. (a) HRTEM image of the interface between nickel ferrite film and MgAl2O4<br />

substrate; (b) Fourier transform of the area in the red box of the HRTEM image, the as left<br />

lattice fringes are from {040} planes...........................................................................................89<br />

Fig. 47. AGM hysteresis loops for nickel ferrite films deposited at 500˚C and 800˚C. The<br />

upper-left inset shows the dependence of the saturation magnetization on deposition<br />

temperature; the lower-right inset shows the dependence of the coercivity on<br />

deposition temperature.................................................................................................................91<br />

Fig. 48. FMR resonance field under different microwave frequencies and crystal orientations<br />

as measured for the nickel ferrite sample deposited at 600˚C. (5 mm × 5 mm, ~780 nm)...........92<br />

xvii