CHEMICAL VAPOR DEPOSITION OF THIN FILM MATERIALS FOR ...

CHEMICAL VAPOR DEPOSITION OF THIN FILM MATERIALS FOR ...

CHEMICAL VAPOR DEPOSITION OF THIN FILM MATERIALS FOR ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Fig. 31. LabVIEW program for the control of PEALD process.<br />

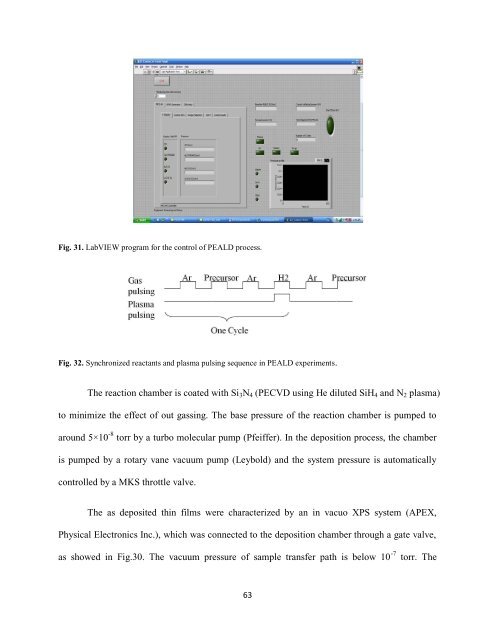

Fig. 32. Synchronized reactants and plasma pulsing sequence in PEALD experiments.<br />

The reaction chamber is coated with Si3N4 (PECVD using He diluted SiH4 and N2 plasma)<br />

to minimize the effect of out gassing. The base pressure of the reaction chamber is pumped to<br />

around 5×10 -8 torr by a turbo molecular pump (Pfeiffer). In the deposition process, the chamber<br />

is pumped by a rotary vane vacuum pump (Leybold) and the system pressure is automatically<br />

controlled by a MKS throttle valve.<br />

The as deposited thin films were characterized by an in vacuo XPS system (APEX,<br />

Physical Electronics Inc.), which was connected to the deposition chamber through a gate valve,<br />

as showed in Fig.30. The vacuum pressure of sample transfer path is below 10 -7 torr. The<br />

63