A GEM Detector System for an Upgrade of the CMS Muon Endcaps

A GEM Detector System for an Upgrade of the CMS Muon Endcaps

A GEM Detector System for an Upgrade of the CMS Muon Endcaps

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

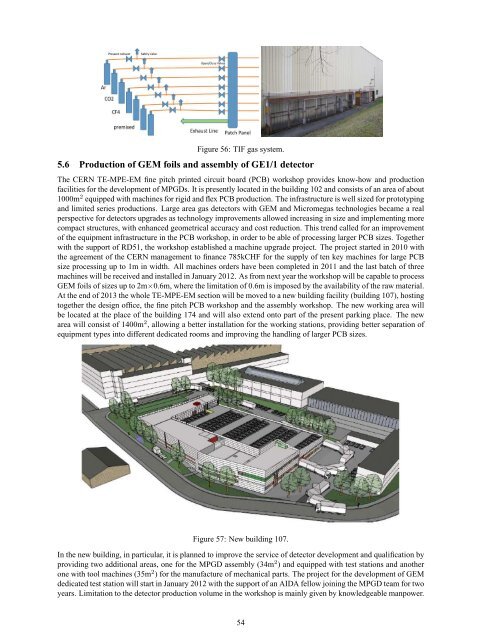

Figure 56: TIF gas system.<br />

5.6 Production <strong>of</strong> <strong>GEM</strong> foils <strong>an</strong>d assembly <strong>of</strong> GE1/1 detector<br />

The CERN TE-MPE-EM fine pitch printed circuit board (PCB) workshop provides know-how <strong>an</strong>d production<br />

facilities <strong>for</strong> <strong>the</strong> development <strong>of</strong> MPGDs. It is presently located in <strong>the</strong> building 102 <strong>an</strong>d consists <strong>of</strong> <strong>an</strong> area <strong>of</strong> about<br />

1000m 2 equipped with machines <strong>for</strong> rigid <strong>an</strong>d flex PCB production. The infrastructure is well sized <strong>for</strong> prototyping<br />

<strong>an</strong>d limited series productions. Large area gas detectors with <strong>GEM</strong> <strong>an</strong>d Micromegas technologies became a real<br />

perspective <strong>for</strong> detectors upgrades as technology improvements allowed increasing in size <strong>an</strong>d implementing more<br />

compact structures, with enh<strong>an</strong>ced geometrical accuracy <strong>an</strong>d cost reduction. This trend called <strong>for</strong> <strong>an</strong> improvement<br />

<strong>of</strong> <strong>the</strong> equipment infrastructure in <strong>the</strong> PCB workshop, in order to be able <strong>of</strong> processing larger PCB sizes. Toge<strong>the</strong>r<br />

with <strong>the</strong> support <strong>of</strong> RD51, <strong>the</strong> workshop established a machine upgrade project. The project started in 2010 with<br />

<strong>the</strong> agreement <strong>of</strong> <strong>the</strong> CERN m<strong>an</strong>agement to fin<strong>an</strong>ce 785kCHF <strong>for</strong> <strong>the</strong> supply <strong>of</strong> ten key machines <strong>for</strong> large PCB<br />

size processing up to 1m in width. All machines orders have been completed in 2011 <strong>an</strong>d <strong>the</strong> last batch <strong>of</strong> three<br />

machines will be received <strong>an</strong>d installed in J<strong>an</strong>uary 2012. As from next year <strong>the</strong> workshop will be capable to process<br />

<strong>GEM</strong> foils <strong>of</strong> sizes up to 2m×0.6m, where <strong>the</strong> limitation <strong>of</strong> 0.6m is imposed by <strong>the</strong> availability <strong>of</strong> <strong>the</strong> raw material.<br />

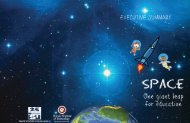

At <strong>the</strong> end <strong>of</strong> 2013 <strong>the</strong> whole TE-MPE-EM section will be moved to a new building facility (building 107), hosting<br />

toge<strong>the</strong>r <strong>the</strong> design <strong>of</strong>fice, <strong>the</strong> fine pitch PCB workshop <strong>an</strong>d <strong>the</strong> assembly workshop. The new working area will<br />

be located at <strong>the</strong> place <strong>of</strong> <strong>the</strong> building 174 <strong>an</strong>d will also extend onto part <strong>of</strong> <strong>the</strong> present parking place. The new<br />

area will consist <strong>of</strong> 1400m 2 , allowing a better installation <strong>for</strong> <strong>the</strong> working stations, providing better separation <strong>of</strong><br />

equipment types into different dedicated rooms <strong>an</strong>d improving <strong>the</strong> h<strong>an</strong>dling <strong>of</strong> larger PCB sizes.<br />

Figure 57: New building 107.<br />

In <strong>the</strong> new building, in particular, it is pl<strong>an</strong>ned to improve <strong>the</strong> service <strong>of</strong> detector development <strong>an</strong>d qualification by<br />

providing two additional areas, one <strong>for</strong> <strong>the</strong> MPGD assembly (34m 2 ) <strong>an</strong>d equipped with test stations <strong>an</strong>d <strong>an</strong>o<strong>the</strong>r<br />

one with tool machines (35m 2 ) <strong>for</strong> <strong>the</strong> m<strong>an</strong>ufacture <strong>of</strong> mech<strong>an</strong>ical parts. The project <strong>for</strong> <strong>the</strong> development <strong>of</strong> <strong>GEM</strong><br />

dedicated test station will start in J<strong>an</strong>uary 2012 with <strong>the</strong> support <strong>of</strong> <strong>an</strong> AIDA fellow joining <strong>the</strong> MPGD team <strong>for</strong> two<br />

years. Limitation to <strong>the</strong> detector production volume in <strong>the</strong> workshop is mainly given by knowledgeable m<strong>an</strong>power.<br />

54