Films minces à base de Si nanostructuré pour des cellules ...

Films minces à base de Si nanostructuré pour des cellules ...

Films minces à base de Si nanostructuré pour des cellules ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

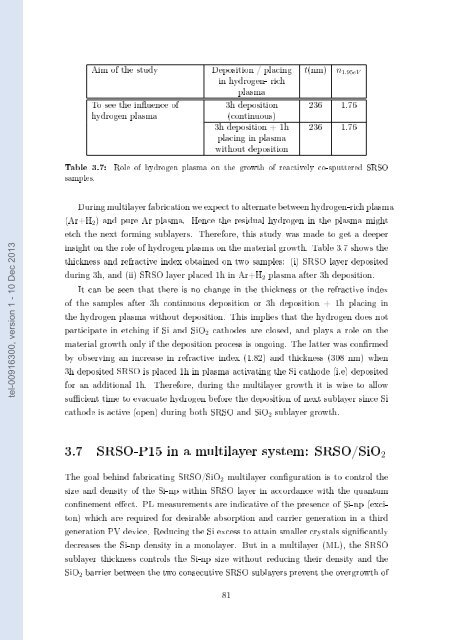

Aim of the study<br />

To see the inuence of<br />

hydrogen plasma<br />

Deposition / placing<br />

in hydrogen- rich<br />

plasma<br />

3h <strong>de</strong>position<br />

(continuous)<br />

3h <strong>de</strong>position + 1h<br />

placing in plasma<br />

without <strong>de</strong>position<br />

t(nm)<br />

n 1.95eV<br />

236 1.76<br />

236 1.76<br />

Table 3.7:<br />

samples.<br />

Role of hydrogen plasma on the growth of reactively co-sputtered SRSO<br />

tel-00916300, version 1 - 10 Dec 2013<br />

During multilayer fabrication we expect to alternate between hydrogen-rich plasma<br />

(Ar+H 2 ) and pure Ar plasma. Hence the residual hydrogen in the plasma might<br />

etch the next forming sublayers. Therefore, this study was ma<strong>de</strong> to get a <strong>de</strong>eper<br />

insight on the role of hydrogen plasma on the material growth. Table 3.7 shows the<br />

thickness and refractive in<strong>de</strong>x obtained on two samples: (i) SRSO layer <strong>de</strong>posited<br />

during 3h, and (ii) SRSO layer placed 1h in Ar+H 2 plasma after 3h <strong>de</strong>position.<br />

It can be seen that there is no change in the thickness or the refractive in<strong>de</strong>x<br />

of the samples after 3h continuous <strong>de</strong>position or 3h <strong>de</strong>position + 1h placing in<br />

the hydrogen plasma without <strong>de</strong>position. This implies that the hydrogen does not<br />

participate in etching if <strong>Si</strong> and <strong>Si</strong>O 2 catho<strong>de</strong>s are closed, and plays a role on the<br />

material growth only if the <strong>de</strong>position process is ongoing. The latter was conrmed<br />

by observing an increase in refractive in<strong>de</strong>x (1.82) and thickness (308 nm) when<br />

3h <strong>de</strong>posited SRSO is placed 1h in plasma activating the <strong>Si</strong> catho<strong>de</strong> (i.e) <strong>de</strong>posited<br />

for an additional 1h. Therefore, during the multilayer growth it is wise to allow<br />

sucient time to evacuate hydrogen before the <strong>de</strong>position of next sublayer since <strong>Si</strong><br />

catho<strong>de</strong> is active (open) during both SRSO and <strong>Si</strong>O 2 sublayer growth.<br />

3.7 SRSO-P15 in a multilayer system: SRSO/<strong>Si</strong>O 2<br />

The goal behind fabricating SRSO/<strong>Si</strong>O 2 multilayer conguration is to control the<br />

size and <strong>de</strong>nsity of the <strong>Si</strong>-np within SRSO layer in accordance with the quantum<br />

connement eect. PL measurements are indicative of the presence of <strong>Si</strong>-np (exciton)<br />

which are required for <strong>de</strong>sirable absorption and carrier generation in a third<br />

generation PV <strong>de</strong>vice. Reducing the <strong>Si</strong> excess to attain smaller crystals signicantly<br />

<strong>de</strong>creases the <strong>Si</strong>-np <strong>de</strong>nsity in a monolayer. But in a multilayer (ML), the SRSO<br />

sublayer thickness controls the <strong>Si</strong>-np size without reducing their <strong>de</strong>nsity and the<br />

<strong>Si</strong>O 2 barrier between the two consecutive SRSO sublayers prevent the overgrowth of<br />

81