Volume 6, Spring 2008 - Saddleback College

Volume 6, Spring 2008 - Saddleback College

Volume 6, Spring 2008 - Saddleback College

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

38<br />

<strong>Saddleback</strong> Journal of Biology<br />

<strong>Spring</strong> <strong>2008</strong><br />

Fall 2007 Biology 3A Abstracts<br />

Gas Production (ml)<br />

0.9<br />

0.8<br />

0.7<br />

0.6<br />

0.5<br />

0.4<br />

0.3<br />

0.2<br />

0.1<br />

0<br />

pH1 pH3 pH5 pH7 pH9<br />

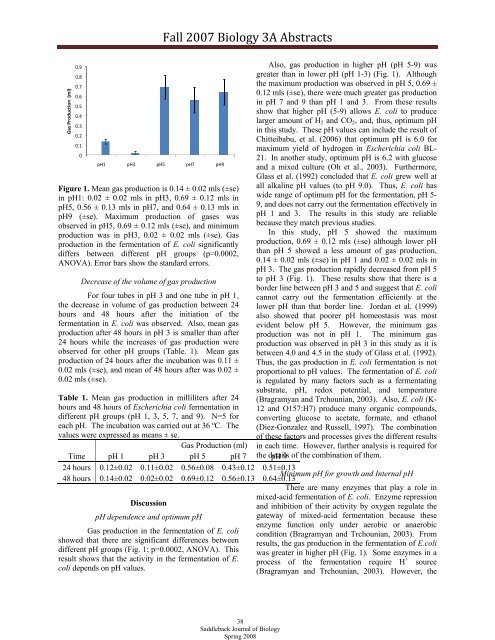

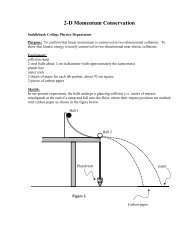

Figure 1. Mean gas production is 0.14 ± 0.02 mls (±se)<br />

in pH1: 0.02 ± 0.02 mls in pH3, 0.69 ± 0.12 mls in<br />

pH5, 0.56 ± 0.13 mls in pH7, and 0.64 ± 0.13 mls in<br />

pH9 (±se). Maximum production of gases was<br />

observed in pH5, 0.69 ± 0.12 mls (±se), and minimum<br />

production was in pH3, 0.02 ± 0.02 mls (±se). Gas<br />

production in the fermentation of E. coli significantly<br />

differs between different pH groups (p=0.0002,<br />

ANOVA). Error bars show the standard errors.<br />

Decrease of the volume of gas production<br />

For four tubes in pH 3 and one tube in pH 1,<br />

the decrease in volume of gas production between 24<br />

hours and 48 hours after the initiation of the<br />

fermentation in E. coli was observed. Also, mean gas<br />

production after 48 hours in pH 3 is smaller than after<br />

24 hours while the increases of gas production were<br />

observed for other pH groups (Table. 1). Mean gas<br />

production of 24 hours after the incubation was 0.11 ±<br />

0.02 mls (±se), and mean of 48 hours after was 0.02 ±<br />

0.02 mls (±se).<br />

Table 1. Mean gas production in milliliters after 24<br />

hours and 48 hours of Escherichia coli fermentation in<br />

different pH groups (pH 1, 3, 5, 7, and 9). N=5 for<br />

each pH. The incubation was carried out at 36 ºC. The<br />

values were expressed as means ± se.<br />

Gas Production (ml)<br />

Time pH 1 pH 3 pH 5 pH 7 pH 9<br />

Also, gas production in higher pH (pH 5-9) was<br />

greater than in lower pH (pH 1-3) (Fig. 1). Although<br />

the maximum production was observed in pH 5, 0.69 ±<br />

0.12 mls (±se), there were much greater gas production<br />

in pH 7 and 9 than pH 1 and 3. From these results<br />

show that higher pH (5-9) allows E. coli to produce<br />

larger amount of H 2 and CO 2 , and, thus, optimum pH<br />

in this study. These pH values can include the result of<br />

Chitteibabu, et al. (2006) that optimum pH is 6.0 for<br />

maximum yield of hydrogen in Escherichia coli BL-<br />

21. In another study, optimum pH is 6.2 with glucose<br />

and a mixed culture (Oh et al., 2003). Furthermore,<br />

Glass et al. (1992) concluded that E. coli grew well at<br />

all alkaline pH values (to pH 9.0). Thus, E. coli has<br />

wide range of optimum pH for the fermentation, pH 5-<br />

9, and does not carry out the fermentation effectively in<br />

pH 1 and 3. The results in this study are reliable<br />

because they match previous studies.<br />

In this study, pH 5 showed the maximum<br />

production, 0.69 ± 0.12 mls (±se) although lower pH<br />

than pH 5 showed a less amount of gas production,<br />

0.14 ± 0.02 mls (±se) in pH 1 and 0.02 ± 0.02 mls in<br />

pH 3. The gas production rapidly decreased from pH 5<br />

to pH 3 (Fig. 1). These results show that there is a<br />

border line between pH 3 and 5 and suggest that E. coli<br />

cannot carry out the fermentation efficiently at the<br />

lower pH than that border line. Jordan et al. (1999)<br />

also showed that poorer pH homeostasis was most<br />

evident below pH 5. However, the minimum gas<br />

production was not in pH 1. The minimum gas<br />

production was observed in pH 3 in this study as it is<br />

between 4.0 and 4.5 in the study of Glass et al. (1992).<br />

Thus, the gas production in E. coli fermentation is not<br />

proportional to pH values. The fermentation of E. coli<br />

is regulated by many factors such as a fermentating<br />

substrate, pH, redox potential, and temperature<br />

(Bragramyan and Trchounian, 2003). Also, E. coli (K-<br />

12 and O157:H7) produce many organic compounds,<br />

converting glucose to acetate, formate, and ethanol<br />

(Diez-Gonzalez and Russell, 1997). The combination<br />

of these factors and processes gives the different results<br />

in each time. However, further analysis is required for<br />

the details of the combination of them.<br />

24 hours 0.12±0.02 0.11±0.02 0.56±0.08 0.43±0.12 0.51±0.13<br />

Minimum pH for growth and Internal pH<br />

48 hours 0.14±0.02 0.02±0.02 0.69±0.12 0.56±0.13 0.64±0.13<br />

There are many enzymes that play a role in<br />

mixed-acid fermentation of E. coli. Enzyme repression<br />

Discussion<br />

and inhibition of their activity by oxygen regulate the<br />

pH dependence and optimum pH<br />

gateway of mixed-acid fermentation because these<br />

enzyme function only under aerobic or anaerobic<br />

Gas production in the fermentation of E. coli condition (Bragramyan and Trchounian, 2003). From<br />

showed that there are significant differences between results, the gas production in the fermentation of E.coli<br />

different pH groups (Fig. 1; p=0.0002, ANOVA). This was greater in higher pH (Fig. 1). Some enzymes in a<br />

result shows that the activity in the fermentation of E. process of the fermentation require H + source<br />

coli depends on pH values.<br />

(Bragramyan and Trchounian, 2003). However, the