Assessment of Conversion Technologies for Bioalcohol Fuel ...

Assessment of Conversion Technologies for Bioalcohol Fuel ...

Assessment of Conversion Technologies for Bioalcohol Fuel ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

successfully demonstrated their technologies by building and systematically testing full<br />

scale operating systems.<br />

Syngas Cleanup and Conditioning<br />

Without sufficient cleanup and conditioning, syngas produced from biomass may not<br />

be useful <strong>for</strong> alcohol synthesis. Synthesis catalysts work optimally with a certain ratio<br />

<strong>of</strong> H 2 to CO, and the effectiveness is reduced when a large concentration <strong>of</strong> inert<br />

compounds (like N 2 ) are introduced to the catalyst system. Catalysts used <strong>for</strong><br />

synthesis can also be extremely sensitive to gaseous contaminants like sulfur,<br />

chlorine, metal poisons and particulate contaminants such as tars. These compounds<br />

occupy active sites <strong>of</strong> the catalyst, reducing catalyst activity and catalyst life. Syngas<br />

cleanup and conditioning strategies must address the major and minor constituents in<br />

the syngas to meet the requirements <strong>of</strong> the catalyst being utilized.<br />

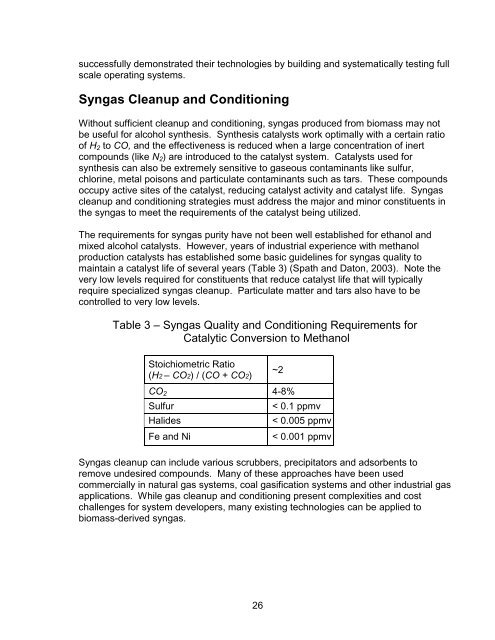

The requirements <strong>for</strong> syngas purity have not been well established <strong>for</strong> ethanol and<br />

mixed alcohol catalysts. However, years <strong>of</strong> industrial experience with methanol<br />

production catalysts has established some basic guidelines <strong>for</strong> syngas quality to<br />

maintain a catalyst life <strong>of</strong> several years (Table 3) (Spath and Daton, 2003). Note the<br />

very low levels required <strong>for</strong> constituents that reduce catalyst life that will typically<br />

require specialized syngas cleanup. Particulate matter and tars also have to be<br />

controlled to very low levels.<br />

Table 3–Syngas Quality and Conditioning Requirements <strong>for</strong><br />

Catalytic <strong>Conversion</strong> to Methanol<br />

Stoichiometric Ratio<br />

(H2–CO2) / (CO + CO2)<br />

~2<br />

CO 2 4-8%<br />

Sulfur<br />

Halides<br />

Fe and Ni<br />

< 0.1 ppmv<br />

< 0.005 ppmv<br />

< 0.001 ppmv<br />

Syngas cleanup can include various scrubbers, precipitators and adsorbents to<br />

remove undesired compounds. Many <strong>of</strong> these approaches have been used<br />

commercially in natural gas systems, coal gasification systems and other industrial gas<br />

applications. While gas cleanup and conditioning present complexities and cost<br />

challenges <strong>for</strong> system developers, many existing technologies can be applied to<br />

biomass-derived syngas.<br />

26