Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

LifeCheck ® SPD Test<br />

SPD<br />

diagnostics with early<br />

warning function!<br />

• Increased protection and availability of your<br />

installations and systems due to integrated<br />

LifeCheck monitoring system<br />

– Integrated three-stage monitoring of all protective<br />

circuit components<br />

– Quick diagnostics of surge protective devices<br />

– Easy testing of protection modules without downtime<br />

via contactless RFID technology<br />

– Even detects previously damaged arresters<br />

Regular testing of arresters installed<br />

During operation, an arrester may be overloaded by discharge processes<br />

exceeding the arrester specification. In order to ensure high system availability,<br />

it is therefore essential to test arresters on a regular basis. DIN EN<br />

62305-3, supplement 3 (see table excerpt), specifies the maximum intervals<br />

between tests of external and internal lightning protection systems.<br />

Class of Visual Complete Complete inspection<br />

LPS inspection inspection of critical systems<br />

I and II 1 year 2 years 1 year<br />

III and IV 2 years 4 years 1 year<br />

Easy testing with LifeCheck<br />

Maintenance of LifeCheck-equipped BLITZDUCTOR XT arresters is particularly<br />

easy. LifeCheck uses modern RFID (Radio Frequency Identification)<br />

technology for monitoring the protective circuit and for communication.<br />

Irrespective of system downtimes, LifeCheck allows quick and easy testing<br />

of arresters by means of the hand-held DRC LC M3+ reader or a stationary<br />

DRC MCM XT condition monitoring unit.<br />

Indication of arrester failure<br />

The three-stage LifeCheck monitoring circuit with early warning function<br />

detects extreme electrical or thermal load on all protection elements of<br />

an arrester below their destruction limit. This can be contactlessly read<br />

out within a matter of seconds by means an RFID reader. If the reader displays<br />

"OK", no extreme load was detected. If the contrary is the case, the<br />

module should be replaced as soon as possible in order not to threaten<br />

the availability of the protected circuit.<br />

1<br />

2<br />

3<br />

4<br />

1´<br />

2´<br />

protected<br />

3‘<br />

4‘<br />

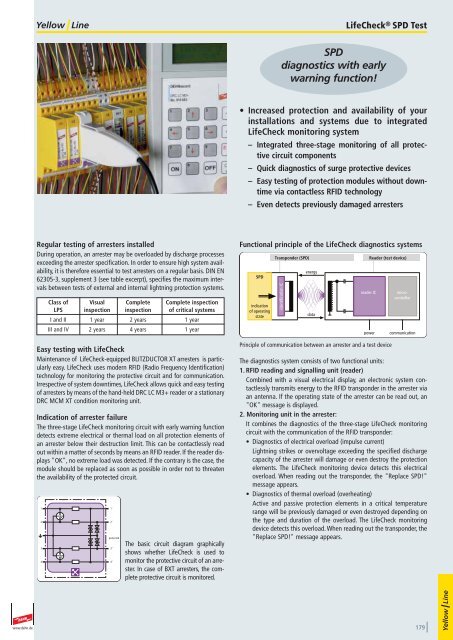

The basic circuit diagram graphically<br />

shows whether LifeCheck is used to<br />

monitor the protective circuit of an arrester.<br />

In case of BXT arresters, the complete<br />

protective circuit is monitored.<br />

Functional principle of the LifeCheck diagnostics systems<br />

SPD<br />

indication<br />

of operating<br />

state<br />

Transponder (SPD)<br />

identification IC<br />

energy<br />

data<br />

reader IC<br />

Reader (test device)<br />

power<br />

Principle of communication between an arrester and a test device<br />

microcontroller<br />

communication<br />

The diagnostics system consists of two functional units:<br />

1. RFID reading and signalling unit (reader)<br />

Combined with a visual electrical display, an electronic system contactlessly<br />

transmits energy to the RFID transponder in the arrester via<br />

an antenna. If the operating state of the arrester can be read out, an<br />

"OK" message is displayed.<br />

2. Monitoring unit in the arrester:<br />

It combines the diagnostics of the three-stage LifeCheck monitoring<br />

circuit with the communication of the RFID transponder:<br />

• Diagnostics of electrical overload (impulse current)<br />

Lightning strikes or overvoltage exceeding the specified discharge<br />

capacity of the arrester will damage or even destroy the protection<br />

elements. The LifeCheck monitoring device detects this electrical<br />

overload. When reading out the transponder, the "Replace SPD!"<br />

message appears.<br />

• Diagnostics of thermal overload (overheating)<br />

Active and passive protection elements in a critical temperature<br />

range will be previously damaged or even destroyed depending on<br />

the type and duration of the overload. The LifeCheck monitoring<br />

device detects this overload. When reading out the transponder, the<br />

"Replace SPD!" message appears.<br />

www.dehn.de<br />

179