- Page 1 and 2:

Surge Protection Main Catalogue 201

- Page 3 and 4:

Contents Page Our promise - DEHN pr

- Page 5 and 6:

DEHN protects Our family-owned comp

- Page 7 and 8:

DEHN - worldwide Algeria Argentina

- Page 9 and 10:

DEHN - Safety according to Specific

- Page 11 and 12:

DEHN - Technical Definitions Lightn

- Page 13 and 14:

Surge protection for POWER SUPPLY S

- Page 15 and 16:

Contents Easy Choice 15 Combined SP

- Page 17 and 18:

S-Schutz Easy Choice L1 L2 L3 N PE

- Page 19 and 20:

Easy Choice L1 L2 L3 N PE 3 A 1 Arr

- Page 21 and 22:

S-Schutz Easy Choice L1 L2 L3 N PE

- Page 23 and 24:

Easy Choice L1 L2 L3 PEN SPD Type 2

- Page 25 and 26:

ÜBERSPANNUNGSSCHUTZ DEFECT FUNCTIO

- Page 27 and 28:

Easy Choice of SPDs for Use on roof

- Page 29 and 30:

DEHN-FUNKENSTRECKEN-TECHNOLOGIE INS

- Page 31 and 32:

Combined SPDs - Type 1 DEHNventil

- Page 33 and 34:

DEHNventil ® modular DEHNventil M

- Page 35 and 36:

Protection Module for DEHNventil ®

- Page 37 and 38:

Combined SPDs - Type 1 DEHNventil

- Page 39 and 40:

Combined SPDs - Type 1 DEHNventil

- Page 41 and 42:

L L' N/PE(N) Combined SPDs - Type 1

- Page 43 and 44:

DEHNshield ® Combined SPDs - Type

- Page 45 and 46:

DEHNshield ® Combined SPDs - Type

- Page 47 and 48:

DEHNshield ® Combined SPDs - Type

- Page 49 and 50:

DEHNlimit PV 1000 V2 (FM) Combined

- Page 51 and 52:

Coordinated Type 1 Lightning Curren

- Page 53 and 54:

Coordinated Type 1 Lightning Curren

- Page 55 and 56:

Coordinated Type 1 Lightning Curren

- Page 57 and 58:

Coordinated Type 1 Lightning Curren

- Page 59 and 60:

L L' Coordinated Type 1 Lightning C

- Page 61 and 62:

Coordinated Type 1 Lightning Curren

- Page 63 and 64:

Accessory for Type 1 Arresters DEHN

- Page 65 and 66:

Coordinated Type 1 Lightning Curren

- Page 67 and 68:

DEHNsecure M DEHNsecure M 2P ... (F

- Page 69 and 70:

Type 1 Lightning Current Arresters

- Page 71 and 72:

Type 1 Lightning Current Arresters

- Page 73 and 74:

N-PE Lightning Current Arresters

- Page 75 and 76:

N-PE Lightning Current Arresters DE

- Page 77 and 78:

N-PE Lightning Current Arresters 30

- Page 79 and 80:

Type 2 Surge Arresters • Arrester

- Page 81 and 82:

S Type 2 Surge Arresters DEHNguard

- Page 83 and 84:

Type 2 Surge Arresters DEHNguard ®

- Page 85 and 86:

Type 2 Surge Arresters DEHNguard ®

- Page 87 and 88:

Type 2 Surge Arresters DEHNguard ®

- Page 89 and 90:

Type 2 Surge Arresters DEHNguard ®

- Page 91 and 92:

Type 2 Surge Arresters DEHNguard ®

- Page 93 and 94:

Type 2 Surge Arresters DEHNguard ®

- Page 95 and 96:

Type 2 Surge Arresters DEHNguard ®

- Page 97 and 98:

S Type 2 Surge Arresters DEHNguard

- Page 99 and 100:

Type 2 Surge Arresters DEHNguard ®

- Page 101 and 102:

S Type 2 Surge Arresters DEHNguard

- Page 103 and 104:

Type 2 Surge Arresters DEHNguard ®

- Page 105 and 106:

Type 2 Surge Arresters • Specific

- Page 107 and 108:

Type 2 Surge Arr. for Use in PV Sys

- Page 109 and 110:

Type 2 Surge Arresters for Use in P

- Page 111 and 112:

Type 2 Surge Arresters for Use in P

- Page 113 and 114:

S Type 2 Surge Arresters Protection

- Page 115 and 116:

Type 2 Surge Arresters • High dis

- Page 117 and 118:

Type 2 Surge Arresters • Surge ar

- Page 119 and 120:

Type 2 Surge Arresters V NH / VA NH

- Page 121 and 122:

Type 3 Surge Arresters • Two-pole

- Page 123 and 124:

Type 3 Surge Arresters DEHNrail mod

- Page 125 and 126:

Type 3 Surge Arresters DEHNrail mod

- Page 127 and 128:

Type 3 Surge Arresters • Protecti

- Page 129 and 130:

Type 3 Surge Arresters SPS Protecto

- Page 131 and 132:

Type 3 Surge Arresters DEHNsafe 31

- Page 133 and 134:

Type 3 Surge Arresters NSM Protecto

- Page 135 and 136:

Type 3 Surge Arresters STC Module 5

- Page 137 and 138:

Type 3 Surge Arresters DEHNflex DEH

- Page 139 and 140:

Type 3 Surge Arresters DEHNflex DEH

- Page 141 and 142:

12 11 L N 12 11 Type 3 Surge Arrest

- Page 143 and 144:

Type 3 Surge Arresters DEHNprotecto

- Page 145 and 146:

Type 3 Surge Arresters • Surge pr

- Page 147 and 148:

Type 3 Surge Arresters L/N SFL Prot

- Page 149 and 150:

General Accessory DEHNpanel • Vis

- Page 151 and 152:

General Accessory • Allows an EMC

- Page 153 and 154:

General Accessory Insulating Enclos

- Page 155 and 156:

General Accessory Busbars / Modular

- Page 157 and 158:

Surge protection for INFORMATION TE

- Page 159 and 160:

1 2 3 4 5 6 7 8 9 0 Contents Easy c

- Page 161 and 162:

Easy Choice according to Interface

- Page 163 and 164:

Easy Choice according to Interface

- Page 165 and 166:

Easy Choice according to Interface

- Page 167 and 168:

Easy Choice according to Interface

- Page 169 and 170:

Easy Choice according to Interface

- Page 171 and 172:

Easy Choice according to Interface

- Page 173 and 174:

Easy Choice according to Interface

- Page 175 and 176:

Easy Choice according to Interface

- Page 177 and 178:

Easy Choice according to Interface

- Page 179 and 180:

SPDs for Information Technology Sys

- Page 181 and 182:

LifeCheck ® SPD Test SPD diagnosti

- Page 183 and 184:

Pluggable DIN Rail Mounted SPDs •

- Page 185 and 186:

Pluggable DIN Rail Mounted SPDs BLI

- Page 187 and 188:

Pluggable DIN Rail Mounted SPDs BLI

- Page 189 and 190:

Pluggable DIN Rail Mounted SPD BLIT

- Page 191 and 192:

Pluggable DIN Rail Mounted SPDs BLI

- Page 193 and 194:

Pluggable DIN Rail Mounted SPDs BLI

- Page 195 and 196:

Pluggable DIN Rail Mounted SPDs BLI

- Page 197 and 198:

Pluggable DIN Rail Mounted SPDs BLI

- Page 199 and 200:

Pluggable DIN Rail Mounted SPDs BLI

- Page 201 and 202:

Pluggable DIN Rail Mounted SPDs BLI

- Page 203 and 204:

Pluggable DIN Rail Mounted SPDs BLI

- Page 205 and 206:

Pluggable DIN Rail Mounted SPDs BLI

- Page 207 and 208:

BLITZDUCTOR ® XT LifeCheck ® Modu

- Page 209 and 210:

Pluggable DIN Rail Mounted SPDs Acc

- Page 211 and 212:

Pluggable DIN Rail Mounted SPDs BLI

- Page 213 and 214:

Compact DIN Rail Mounted SPDs • M

- Page 215 and 216:

Compact DIN Rail Mounted SPDs DEHNc

- Page 217 and 218:

Compact DIN Rail Mounted SPDs DEHNc

- Page 219 and 220:

Compact DIN Rail Mounted SPDs DEHNc

- Page 221 and 222:

Compact DIN Rail Mounted SPDs Acces

- Page 223 and 224:

Compact DIN Rail Mounted SPDs BLITZ

- Page 225 and 226:

Compact DIN Rail Mounted SPDs BLITZ

- Page 227 and 228:

Compact DIN Rail Mounted SPDs BLITZ

- Page 229 and 230:

Compact DIN Rail Mounted SPDs BLITZ

- Page 231 and 232:

D P M P Compact DIN Rail Mounted SP

- Page 233 and 234:

SPDs for LSA Technology • Variabl

- Page 235 and 236:

SPDs for LSA Technology DEHNrapid

- Page 237 and 238:

SPDs for LSA Technology DEHNrapid

- Page 239 and 240:

SPDs for LSA Technology DEHNrapid

- Page 241 and 242:

SPDs for LSA Technology Accessories

- Page 243 and 244:

SPDs for LSA Technology • Suitabl

- Page 245 and 246:

SPDs for LSA Technology • Premoun

- Page 247 and 248:

SPDs for LSA Technology Accessories

- Page 249 and 250:

SPDs for LSA Technology Accessories

- Page 251 and 252:

SPDs for 482.6 mm (19 inch) Data Ca

- Page 253 and 254:

SPDs for 482.6 mm (19 inch) Data Ca

- Page 255 and 256:

SPDs for 482.6 mm (19 inch) Data Ca

- Page 257 and 258:

SPDs for RJ Connection • Patch ca

- Page 259 and 260:

SPDs for RJ Connection DEHNpatch DE

- Page 261 and 262:

SPDs for RJ Connection BLITZDUCTOR

- Page 263 and 264:

SPDs for RJ Connection • Surge ar

- Page 265 and 266:

Surface-Mounted SPDs • Combined l

- Page 267 and 268:

DEHNbox Surface-Mounted SPDs 93 54

- Page 269 and 270:

Surface-Mounted SPDs DEHNlink DLI I

- Page 271 and 272:

Surface-Mounted SPDs DEHNlink DLI T

- Page 273 and 274:

SPDs for Coaxial Connection • Plu

- Page 275 and 276:

SPDs for Coaxial Connection DEHNgat

- Page 277 and 278:

5-3000 MHz SPD No. 909 703 I N 2A U

- Page 279 and 280:

SPDs for Coaxial Connection DEHNgat

- Page 281 and 282:

SPDs for Coaxial Connection DEHNgat

- Page 283 and 284:

SPDs for Coaxial Connection DEHNgat

- Page 285 and 286:

SPDs for Coaxial Connection Accesso

- Page 287 and 288:

SPDs for D-SUB Connection • Surge

- Page 289 and 290:

SPDs for D-SUB Connection FS / USD

- Page 291 and 292:

SPDs for D-SUB Connection FS / USD

- Page 293 and 294:

SPDs for D-SUB Connection FS / USD

- Page 295 and 296:

a1 b1 a2 b2 SPDs for Terminal Conne

- Page 297 and 298:

SPDs for Terminal Connection DSM DS

- Page 299 and 300:

SPDs for Terminal Connection BUStec

- Page 301 and 302:

DEHNpipe DEHNpipe arrester series f

- Page 303 and 304:

929 941 DPI MD 24 M 2S DPI MD 24 M

- Page 305 and 306:

Screwable SPDs Accessories for DEHN

- Page 307 and 308:

SPDs for Use in Potentially Explosi

- Page 309 and 310:

SPDs for Use in Potentially Explosi

- Page 311 and 312:

SPDs for Use in Potentially Explosi

- Page 313 and 314:

SPDs for Use in Potentially Explosi

- Page 315 and 316:

SPDs for Use in Potentially Explosi

- Page 317 and 318:

SPDs for Use in Potentially Explosi

- Page 319 and 320: SPDs for Use in Potentially Explosi

- Page 321 and 322: SPDs for Use in Potentially Explosi

- Page 323 and 324: SPDs for Use in Potentially Explosi

- Page 325 and 326: SPDs for Use in Potentially Explosi

- Page 327 and 328: SPDs for Use in Potentially Explosi

- Page 329 and 330: SPDs for Use in Potentially Explosi

- Page 331 and 332: SPDs for Use in Potentially Explosi

- Page 333 and 334: SPDs for Use in Potentially Explosi

- Page 335 and 336: Accessory for Terminal Block System

- Page 337 and 338: Accessory for Terminal Block System

- Page 339 and 340: Accessory for Terminal Block System

- Page 341 and 342: Accessory for Terminal Block System

- Page 343 and 344: Accessory for Terminal Block System

- Page 345 and 346: Combined Adapters • Surge protect

- Page 347 and 348: 909 310 DPRO 230 NT DPRO 230 NT 909

- Page 349 and 350: 909 321 DPRO 230 LAN100 DPRO 230 LA

- Page 351 and 352: Lightning Equipotential Bonding Iso

- Page 353 and 354: Lightning Equipotential Bonding Iso

- Page 355 and 356: Lightning Equipotential Bonding Iso

- Page 357 and 358: Lightning Equipotential Bonding Iso

- Page 359 and 360: Lightning Equipotential Bonding Iso

- Page 361 and 362: Lightning Equipotential Bonding Pip

- Page 363 and 364: Lightning Equipotential Bonding Iso

- Page 365 and 366: Lightning Equipotential Bonding Equ

- Page 367 and 368: Lightning Equipotential Bonding Equ

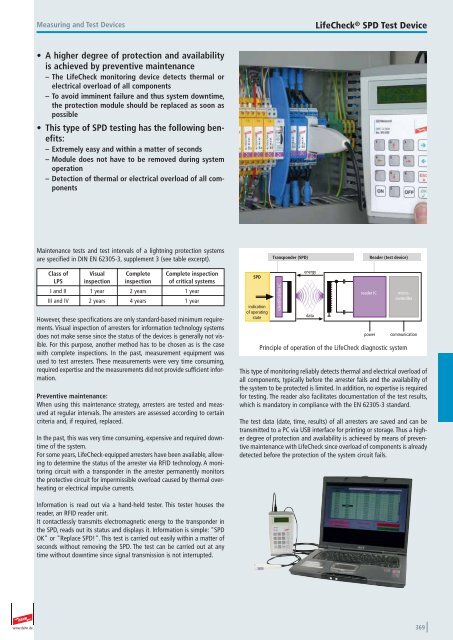

- Page 369: Measuring and Test Devices Conditio

- Page 373 and 374: Measuring and Test Devices SPD Test

- Page 375 and 376: Measuring and Test Devices • SPD

- Page 377 and 378: www.dehn.de 375

- Page 379 and 380: Information and Documentation Publi

- Page 381 and 382: Literature IEC 61643-21:2009-04 Low

- Page 383 and 384: Key to Symbols used in Basic Circui

- Page 385 and 386: Part No. Index Part No. Type Page P

- Page 387 and 388: Part No. Index Part No. Type Page P

- Page 389 and 390: Type / Product Index Type Part No.

- Page 391 and 392: Type / Product Index Type Part No.

- Page 393 and 394: Type / Product Index Type Part No.

- Page 395: Surge Protection Lightning Protecti