ASD/LRFD Manual - American Wood Council

ASD/LRFD Manual - American Wood Council

ASD/LRFD Manual - American Wood Council

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

60 M9: WOOD STRUCTURAL PANELS<br />

M9.1 General<br />

Product Description<br />

<strong>Wood</strong> structural panels are wood-based panel products<br />

that have been rated for use in structural applications. Common<br />

applications for wood structural panels include roof<br />

sheathing, wall sheathing, subflooring, and single-layer<br />

flooring (combination subfloor-underlayment). Plywood<br />

is also manufactured in various sanded grades.<br />

<strong>Wood</strong> structural panels are classified by span ratings.<br />

Panel span ratings identify the maximum recommended<br />

support spacings for specific end uses. Design capacities<br />

are provided on the basis of span ratings.<br />

Sanded grades are classed according to nominal thickness<br />

and design capacities are provided on that basis.<br />

Designers must specify wood structural panels by the<br />

span ratings, nominal thicknesses, grades, and constructions<br />

associated with tabulated design recommendations.<br />

Exposure durability classification must also be identified.<br />

Single Floor panels may have tongue-and-groove<br />

or square edges. If square edge Single Floor panels are<br />

specified, the specification shall require lumber blocking<br />

between supports.<br />

Table M9.1-1 provides descriptions and typical uses<br />

for various panel grades and types.<br />

M9.2 Reference Design Values<br />

General<br />

<strong>Wood</strong> structural panel design capacities listed in Tables<br />

M9.2-1 through M9.2-2 are minimum for grade and span<br />

rating. Multipliers shown in each table provide adjustments<br />

in capacity for Structural I panel grades. To take<br />

advantage of these multipliers, the specifier must insure<br />

that the correct panel is used in construction.<br />

The tabulated capacities and adjustment factors are<br />

based on data from tests of panels manufactured in accordance<br />

with industry standards and which bear the<br />

trademark of a qualified inspection and testing agency.<br />

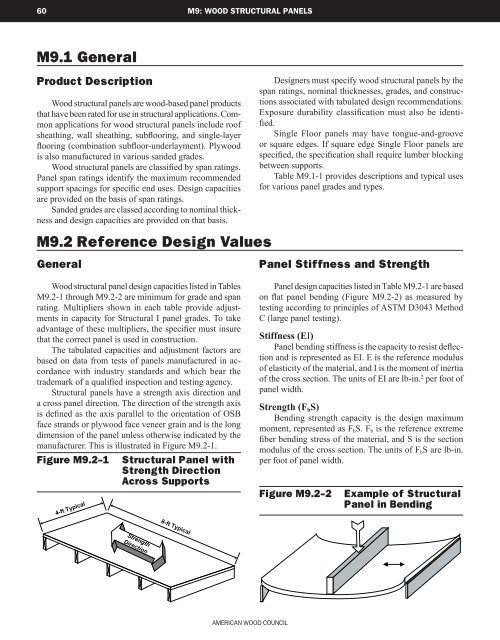

Structural panels have a strength axis direction and<br />

a cross panel direction. The direction of the strength axis<br />

is defined as the axis parallel to the orientation of OSB<br />

face strands or plywood face veneer grain and is the long<br />

dimension of the panel unless otherwise indicated by the<br />

manufacturer. This is illustrated in Figure M9.2-1.<br />

Figure M9.2-1<br />

4-ft Typical<br />

Structural Panel with<br />

Strength Direction<br />

Across Supports<br />

Panel Stiffness and Strength<br />

Panel design capacities listed in Table M9.2-1 are based<br />

on flat panel bending (Figure M9.2-2) as measured by<br />

testing according to principles of ASTM D3043 Method<br />

C (large panel testing).<br />

Stiffness (EI)<br />

Panel bending stiffness is the capacity to resist deflection<br />

and is represented as EI. E is the reference modulus<br />

of elasticity of the material, and I is the moment of inertia<br />

of the cross section. The units of EI are lb-in. 2 per foot of<br />

panel width.<br />

Strength (F b S)<br />

Bending strength capacity is the design maximum<br />

moment, represented as F b S. F b is the reference extreme<br />

fiber bending stress of the material, and S is the section<br />

modulus of the cross section. The units of F b S are lb-in.<br />

per foot of panel width.<br />

Figure M9.2-2<br />

Example of Structural<br />

Panel in Bending<br />

8-ft Typical<br />

Strength<br />

Direction<br />

<strong>American</strong> <strong>Wood</strong> <strong>Council</strong>