ASD/LRFD Manual - American Wood Council

ASD/LRFD Manual - American Wood Council

ASD/LRFD Manual - American Wood Council

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>ASD</strong>/<strong>LRFD</strong> MANUAL FOR ENGINEERED <strong>Wood</strong> Construction<br />

83<br />

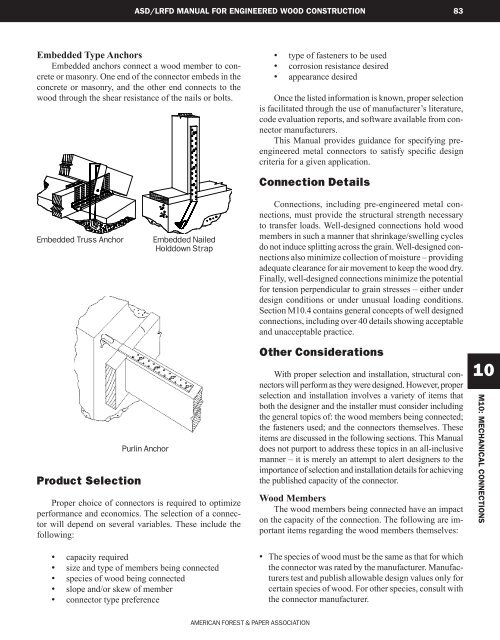

Embedded Type Anchors<br />

Embedded anchors connect a wood member to concrete<br />

or masonry. One end of the connector embeds in the<br />

concrete or masonry, and the other end connects to the<br />

wood through the shear resistance of the nails or bolts.<br />

• type of fasteners to be used<br />

• corrosion resistance desired<br />

• appearance desired<br />

Once the listed information is known, proper selection<br />

is facilitated through the use of manufacturer’s literature,<br />

code evaluation reports, and software available from connector<br />

manufacturers.<br />

This <strong>Manual</strong> provides guidance for specifying preengineered<br />

metal connectors to satisfy specific design<br />

criteria for a given application.<br />

Embedded Truss Anchor<br />

Embedded Nailed<br />

Holddown Strap<br />

Connection Details<br />

Connections, including pre-engineered metal connections,<br />

must provide the structural strength necessary<br />

to transfer loads. Well-designed connections hold wood<br />

members in such a manner that shrinkage/swelling cycles<br />

do not induce splitting across the grain. Well-designed connections<br />

also minimize collection of moisture – providing<br />

adequate clearance for air movement to keep the wood dry.<br />

Finally, well-designed connections minimize the potential<br />

for tension perpendicular to grain stresses – either under<br />

design conditions or under unusual loading conditions.<br />

Section M10.4 contains general concepts of well designed<br />

connections, including over 40 details showing acceptable<br />

and unacceptable practice.<br />

Product Selection<br />

Purlin Anchor<br />

Proper choice of connectors is required to optimize<br />

performance and economics. The selection of a connector<br />

will depend on several variables. These include the<br />

following:<br />

Other Considerations<br />

With proper selection and installation, structural connectors<br />

will perform as they were designed. However, proper<br />

selection and installation involves a variety of items that<br />

both the designer and the installer must consider including<br />

the general topics of: the wood members being connected;<br />

the fasteners used; and the connectors themselves. These<br />

items are discussed in the following sections. This <strong>Manual</strong><br />

does not purport to address these topics in an all-inclusive<br />

manner – it is merely an attempt to alert designers to the<br />

importance of selection and installation details for achieving<br />

the published capacity of the connector.<br />

<strong>Wood</strong> Members<br />

The wood members being connected have an impact<br />

on the capacity of the connection. The following are important<br />

items regarding the wood members themselves:<br />

10<br />

M10: MECHANICAL CONNECTIONS<br />

• capacity required<br />

• size and type of members being connected<br />

• species of wood being connected<br />

• slope and/or skew of member<br />

• connector type preference<br />

• The species of wood must be the same as that for which<br />

the connector was rated by the manufacturer. Manufacturers<br />

test and publish allowable design values only for<br />

certain species of wood. For other species, consult with<br />

the connector manufacturer.<br />

<strong>American</strong> Forest & paper association