Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

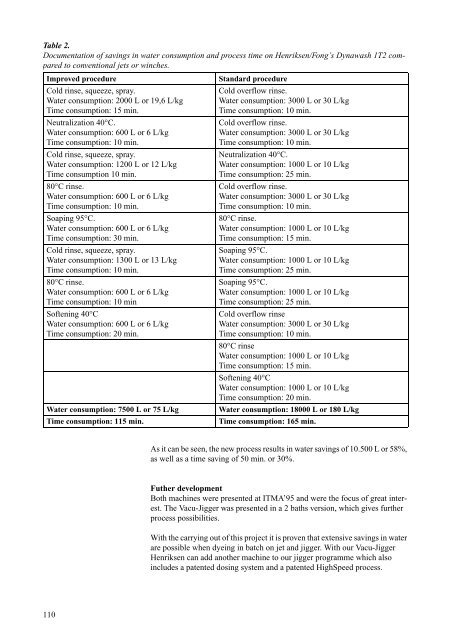

Table 2.<br />

Documentation of savings in water consumption and process time on Henriksen/Fong’s Dynawash 1T2 compared<br />

<strong>to</strong> conventional jets or winches.<br />

Improved procedure Standard procedure<br />

Cold rinse, squeeze, spray.<br />

Water consumption: 2000 L or 19,6 L/kg<br />

Time consumption: 15 min.<br />

Neutralization 40°C.<br />

Water consumption: 600 L or 6 L/kg<br />

Time consumption: 10 min.<br />

Cold rinse, squeeze, spray.<br />

Water consumption: 1200 L or 12 L/kg<br />

Time consumption 10 min.<br />

80°C rinse.<br />

Water consumption: 600 L or 6 L/kg<br />

Time consumption: 10 min.<br />

Soaping 95°C.<br />

Water consumption: 600 L or 6 L/kg<br />

Time consumption: 30 min.<br />

Cold rinse, squeeze, spray.<br />

Water consumption: 1300 L or 13 L/kg<br />

Time consumption: 10 min.<br />

80°C rinse.<br />

Water consumption: 600 L or 6 L/kg<br />

Time consumption: 10 min<br />

Softening 40°C<br />

Water consumption: 600 L or 6 L/kg<br />

Time consumption: 20 min.<br />

110<br />

Cold overflow rinse.<br />

Water consumption: 3000 L or 30 L/kg<br />

Time consumption: 10 min.<br />

Cold overflow rinse.<br />

Water consumption: 3000 L or 30 L/kg<br />

Time consumption: 10 min.<br />

Neutralization 40°C.<br />

Water consumption: 1000 L or 10 L/kg<br />

Time consumption: 25 min.<br />

Cold overflow rinse.<br />

Water consumption: 3000 L or 30 L/kg<br />

Time consumption: 10 min.<br />

80°C rinse.<br />

Water consumption: 1000 L or 10 L/kg<br />

Time consumption: 15 min.<br />

Soaping 95°C.<br />

Water consumption: 1000 L or 10 L/kg<br />

Time consumption: 25 min.<br />

Soaping 95°C.<br />

Water consumption: 1000 L or 10 L/kg<br />

Time consumption: 25 min.<br />

Cold overflow rinse<br />

Water consumption: 3000 L or 30 L/kg<br />

Time consumption: 10 min.<br />

80°C rinse<br />

Water consumption: 1000 L or 10 L/kg<br />

Time consumption: 15 min.<br />

Softening 40°C<br />

Water consumption: 1000 L or 10 L/kg<br />

Time consumption: 20 min.<br />

Water consumption: 7500 L or 75 L/kg Water consumption: 18000 L or 180 L/kg<br />

Time consumption: 115 min. Time consumption: 165 min.<br />

As it can be seen, <strong>the</strong> new process results in water savings of 10.500 L or 58%,<br />

as well as a time saving of 50 min. or 30%.<br />

Fu<strong>the</strong>r development<br />

Both machines were presented at ITMA’95 and were <strong>the</strong> focus of great interest.<br />

The Vacu-Jigger was presented in a 2 baths version, which gives fur<strong>the</strong>r<br />

process possibilities.<br />

With <strong>the</strong> carrying out of this project it is proven that extensive savings in water<br />

are possible when dyeing in batch on jet and jigger. With our Vacu-Jigger<br />

Henriksen can add ano<strong>the</strong>r machine <strong>to</strong> our jigger programme which also<br />

includes a patented dosing system and a patented HighSpeed process.