Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The conclusion based on lab-scale results was that waste-water from reactive<br />

dyeing of cellulose can be treated with activated carbon <strong>to</strong> an extent, that <strong>the</strong><br />

purified water can be re-used for <strong>the</strong> dye-bath with its content of salt, some<br />

alkali and energy. The results, however needed verification on a larger scale,<br />

and subsequently semifull-scale and full-scale tests were <strong>the</strong>refore conducted.<br />

Semi-full-scale activated carbon treatment plant<br />

Investigations were carried out with a semi-full-scale activated carbon treatment<br />

plant, comprising two 400 1 serial tanks and working with a capacity of<br />

400 l/h. Retention time, thus, 1 h per tank.<br />

More than 10 m 3 have been run through <strong>the</strong> plant without reaching <strong>the</strong> adsorption<br />

capacity of <strong>the</strong> carbon.<br />

Full-scale test dyeings<br />

A series of test dyeings have been carried out at <strong>the</strong> dye-house on small but<br />

ordinary production machines. Approx. 25 kg of cot<strong>to</strong>n knitwear were dyed<br />

with a liquor ratio of between 1:14 and 1:16.<br />

The water for <strong>the</strong> dye-baths came from former exhausted dye-baths plus some<br />

first rinsing baths after a treatment in <strong>the</strong> activated carbon plant.<br />

The following types of dye-stuffs were used:<br />

• Remazol<br />

• Cibacron C and F<br />

• Drimaren X<br />

In all cases, <strong>the</strong> results of <strong>the</strong> dyeings were tested by <strong>the</strong> dye-house staff. In all<br />

cases <strong>the</strong> dyeings were accepted and normal fastness levels were reached. The<br />

lots were delivered <strong>to</strong> – and accepted by – <strong>the</strong> custumers.<br />

As <strong>the</strong> purified waste-water <strong>to</strong> be used as process water contains salt and<br />

alkali, measurements must be carried out of salinity and pH before adjusting<br />

<strong>the</strong> amounts of salt and alkali.<br />

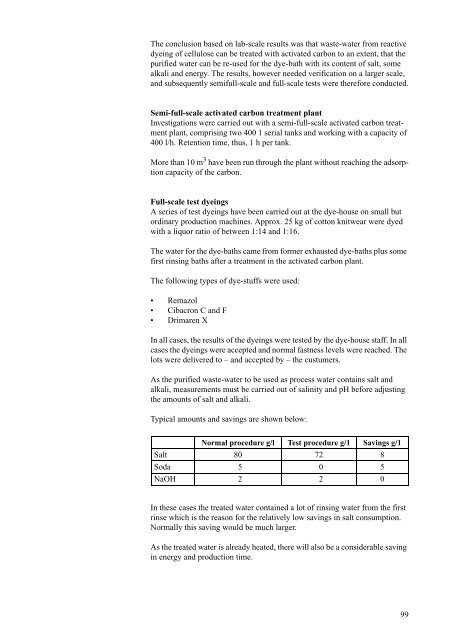

Typical amounts and savings are shown below:<br />

Normal procedure g/l Test procedure g/1 Savings g/1<br />

Salt 80 72 8<br />

Soda 5 0 5<br />

NaOH 2 2 0<br />

In <strong>the</strong>se cases <strong>the</strong> treated water contained a lot of rinsing water from <strong>the</strong> first<br />

rinse which is <strong>the</strong> reason for <strong>the</strong> relatively low savings in salt consumption.<br />

Normally this saving would be much larger.<br />

As <strong>the</strong> treated water is already heated, <strong>the</strong>re will also be a considerable saving<br />

in energy and production time.<br />

99