Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

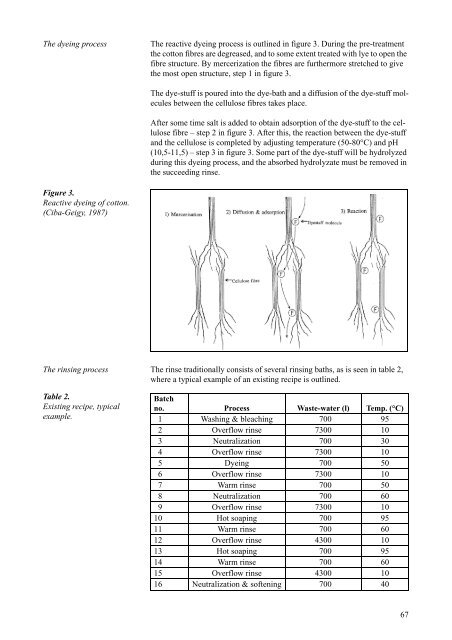

The dyeing process The reactive dyeing process is outlined in figure 3. During <strong>the</strong> pre-treatment<br />

<strong>the</strong> cot<strong>to</strong>n fibres are degreased, and <strong>to</strong> some extent treated with lye <strong>to</strong> open <strong>the</strong><br />

fibre structure. By mercerization <strong>the</strong> fibres are fur<strong>the</strong>rmore stretched <strong>to</strong> give<br />

<strong>the</strong> most open structure, step 1 in figure 3.<br />

Figure 3.<br />

Reactive dyeing of cot<strong>to</strong>n.<br />

(Ciba-Geigy, 1987)<br />

The dye-stuff is poured in<strong>to</strong> <strong>the</strong> dye-bath and a diffusion of <strong>the</strong> dye-stuff molecules<br />

between <strong>the</strong> cellulose fibres takes place.<br />

After some time salt is added <strong>to</strong> obtain adsorption of <strong>the</strong> dye-stuff <strong>to</strong> <strong>the</strong> cellulose<br />

fibre – step 2 in figure 3. After this, <strong>the</strong> reaction between <strong>the</strong> dye-stuff<br />

and <strong>the</strong> cellulose is completed by adjusting temperature (50-80°C) and pH<br />

(10,5-11,5) – step 3 in figure 3. Some part of <strong>the</strong> dye-stuff will be hydrolyzed<br />

during this dyeing process, and <strong>the</strong> absorbed hydrolyzate must be removed in<br />

<strong>the</strong> succeeding rinse.<br />

The rinsing process The rinse traditionally consists of several rinsing baths, as is seen in table 2,<br />

where a typical example of an existing recipe is outlined.<br />

Table 2.<br />

Existing recipe, typical<br />

example.<br />

Batch<br />

no. Process Waste-water (l) Temp. (°C)<br />

1 Washing & bleaching 700 95<br />

2 Overflow rinse 7300 10<br />

3 Neutralization 700 30<br />

4 Overflow rinse 7300 10<br />

5 Dyeing 700 50<br />

6 Overflow rinse 7300 10<br />

7 Warm rinse 700 50<br />

8 Neutralization 700 60<br />

9 Overflow rinse 7300 10<br />

10 Hot soaping 700 95<br />

11 Warm rinse 700 60<br />

12 Overflow rinse 4300 10<br />

13 Hot soaping 700 95<br />

14 Warm rinse 700 60<br />

15 Overflow rinse 4300 10<br />

16 Neutralization & softening 700 40<br />

67