Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

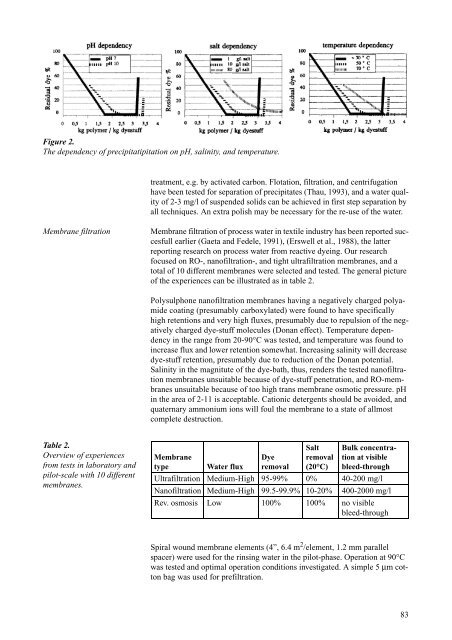

Figure 2.<br />

The dependency of precipitatipitation on pH, salinity, and temperature.<br />

treatment, e.g. by activated carbon. Flotation, filtration, and centrifugation<br />

have been tested for separation of precipitates (Thau, 1993), and a water quality<br />

of 2-3 mg/l of suspended solids can be achieved in first step separation by<br />

all techniques. An extra polish may be necessary for <strong>the</strong> re-use of <strong>the</strong> water.<br />

Membrane filtration Membrane filtration of process water in textile industry has been reported succesfull<br />

earlier (Gaeta and Fedele, 1991), (Erswell et al., 1988), <strong>the</strong> latter<br />

reporting research on process water from reactive dyeing. Our research<br />

focused on RO-, nanofiltration-, and tight ultrafiltration membranes, and a<br />

<strong>to</strong>tal of 10 different membranes were selected and tested. The general picture<br />

of <strong>the</strong> experiences can be illustrated as in table 2.<br />

Table 2.<br />

Overview of experiences<br />

from tests in labora<strong>to</strong>ry and<br />

pilot-scale with 10 different<br />

membranes.<br />

Polysulphone nanofiltration membranes having a negatively charged polyamide<br />

coating (presumably carboxylated) were found <strong>to</strong> have specifically<br />

high retentions and very high fluxes, presumably due <strong>to</strong> repulsion of <strong>the</strong> negatively<br />

charged dye-stuff molecules (Donan effect). Temperature dependency<br />

in <strong>the</strong> range from 20-90°C was tested, and temperature was found <strong>to</strong><br />

increase flux and lower retention somewhat. Increasing salinity will decrease<br />

dye-stuff retention, presumably due <strong>to</strong> reduction of <strong>the</strong> Donan potential.<br />

Salinity in <strong>the</strong> magnitute of <strong>the</strong> dye-bath, thus, renders <strong>the</strong> tested nanofiltration<br />

membranes unsuitable because of dye-stuff penetration, and RO-membranes<br />

unsuitable because of <strong>to</strong>o high trans membrane osmotic pressure. pH<br />

in <strong>the</strong> area of 2-11 is acceptable. Cationic detergents should be avoided, and<br />

quaternary ammonium ions will foul <strong>the</strong> membrane <strong>to</strong> a state of allmost<br />

complete destruction.<br />

Membrane<br />

type Water flux<br />

Dye<br />

removal<br />

Salt<br />

removal<br />

(20°C)<br />

Bulk concentration<br />

at visible<br />

bleed-through<br />

Ultrafiltration Medium-High 95-99% 0% 40-200 mg/l<br />

Nanofiltration Medium-High 99.5-99.9% 10-20% 400-2000 mg/l<br />

Rev. osmosis Low 100% 100% no visible<br />

bleed-through<br />

Spiral wound membrane elements (4”, 6.4 m 2 /element, 1.2 mm parallel<br />

spacer) were used for <strong>the</strong> rinsing water in <strong>the</strong> pilot-phase. Operation at 90°C<br />

was tested and optimal operation conditions investigated. A simple 5 µm cot<strong>to</strong>n<br />

bag was used for prefiltration.<br />

83