Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

68<br />

The large water consumption in <strong>the</strong> rinse step is primarily caused by <strong>the</strong> large<br />

number of baths but also by <strong>the</strong> common use of overflow rinses. Before <strong>the</strong> temperature<br />

is raised in <strong>the</strong> rinse, <strong>the</strong> dye-stuff producers recommend a neutralization<br />

when dye-stuff types with a VS reactive group are used. This neutralization<br />

has, however, in some dye-houses, become usual practice for all recipes.<br />

After neutralization <strong>the</strong> rinse consists of a number of soaping sequences: hot<br />

soaping, warm rinse and overflow rinse. Table 2 shows a typical use of two<br />

soaping sequences. In <strong>the</strong> hot soaping – bath no. 10 and 13 in table 2 – »soaping«<br />

additives are used, covering surface active agents (detergents), complexing<br />

agents and dispersing agents.<br />

The reason for <strong>the</strong> use of complexing agents is protection against hardness in<br />

<strong>the</strong> water and/or <strong>the</strong> cot<strong>to</strong>n <strong>to</strong>ge<strong>the</strong>r with a need for an additive <strong>to</strong> hold <strong>the</strong> dyestuff<br />

hydrolysate dispersed in <strong>the</strong> water.<br />

The process is finalized with neutralization and treatment with softening<br />

agents, necessary for <strong>the</strong> following sewing process.<br />

Materials & methods<br />

Cot<strong>to</strong>n in <strong>the</strong> experiments All analyzed qualities of cot<strong>to</strong>n, also <strong>the</strong> qualities used in <strong>the</strong> experiments, have<br />

a ra<strong>the</strong>r constant <strong>to</strong>tal calcium and magnesium content of about 1500 mg/kg.<br />

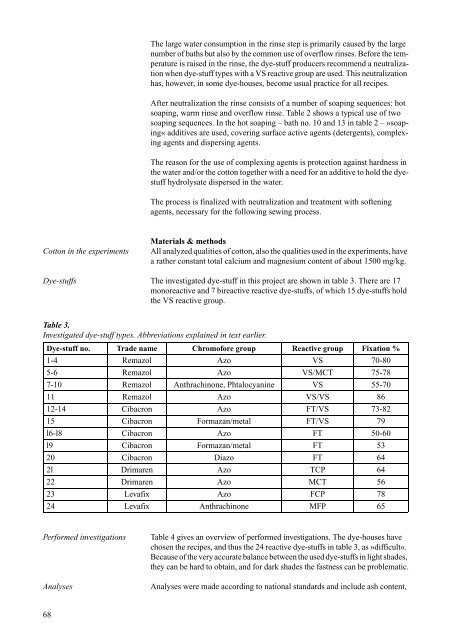

Dye-stuffs The investigated dye-stuff in this project are shown in table 3. There are 17<br />

monoreactive and 7 bireactive reactive dye-stuffs, of which 15 dye-stuffs hold<br />

<strong>the</strong> VS reactive group.<br />

Table 3.<br />

Investigated dye-stuff types. Abbreviations explained in text earlier.<br />

Dye-stuff no. Trade name Chromofore group Reactive group Fixation %<br />

1-4 Remazol Azo VS 70-80<br />

5-6 Remazol Azo VS/MCT 75-78<br />

7-10 Remazol Anthrachinone, Phtalocyanine VS 55-70<br />

11 Remazol Azo VS/VS 86<br />

12-14 Cibacron Azo FT/VS 73-82<br />

15 Cibacron Formazan/metal FT/VS 79<br />

l6-l8 Cibacron Azo FT 50-60<br />

l9 Cibacron Formazan/metal FT 53<br />

20 Cibacron Diazo FT 64<br />

2l Drimaren Azo TCP 64<br />

22 Drimaren Azo MCT 56<br />

23 Levafix Azo FCP 78<br />

24 Levafix Anthrachinone MFP 65<br />

Performed investigations Table 4 gives an overview of performed investigations. The dye-houses have<br />

chosen <strong>the</strong> recipes, and thus <strong>the</strong> 24 reactive dye-stuffs in table 3, as »difficult«.<br />

Because of <strong>the</strong> very accurate balance between <strong>the</strong> used dye-stuffs in light shades,<br />

<strong>the</strong>y can be hard <strong>to</strong> obtain, and for dark shades <strong>the</strong> fastness can be problematic.<br />

Analyses Analyses were made according <strong>to</strong> national standards and include ash content,