Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

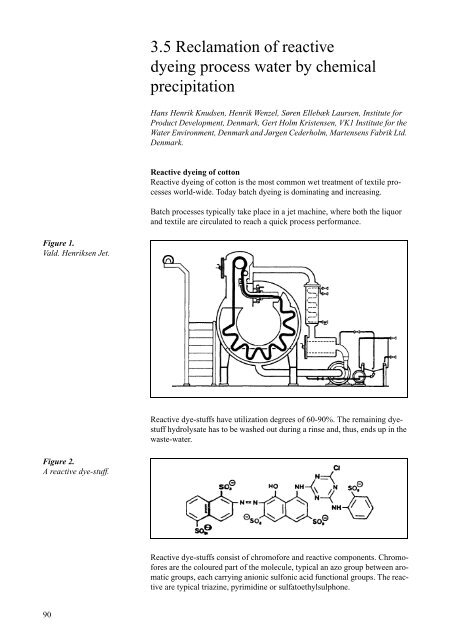

Figure 1.<br />

Vald. Henriksen Jet.<br />

Figure 2.<br />

A reactive dye-stuff.<br />

90<br />

3.5 Reclamation of reactive<br />

dyeing process water by chemical<br />

precipitation<br />

Hans Henrik Knudsen, Henrik Wenzel, Søren Ellebæk Laursen, Institute for<br />

Product Development, Denmark, Gert Holm Kristensen, VK1 Institute for <strong>the</strong><br />

Water Environment, Denmark and Jørgen Cederholm, Martensens Fabrik Ltd.<br />

Denmark.<br />

Reactive dyeing of cot<strong>to</strong>n<br />

Reactive dyeing of cot<strong>to</strong>n is <strong>the</strong> most common wet treatment of textile processes<br />

world-wide. Today batch dyeing is dominating and increasing.<br />

Batch processes typically take place in a jet machine, where both <strong>the</strong> liquor<br />

and textile are circulated <strong>to</strong> reach a quick process performance.<br />

Reactive dye-stuffs have utilization degrees of 60-90%. The remaining dyestuff<br />

hydrolysate has <strong>to</strong> be washed out during a rinse and, thus, ends up in <strong>the</strong><br />

waste-water.<br />

Reactive dye-stuffs consist of chromofore and reactive components. Chromofores<br />

are <strong>the</strong> coloured part of <strong>the</strong> molecule, typical an azo group between aromatic<br />

groups, each carrying anionic sulfonic acid functional groups. The reactive<br />

are typical triazine, pyrimidine or sulfa<strong>to</strong>ethylsulphone.