Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

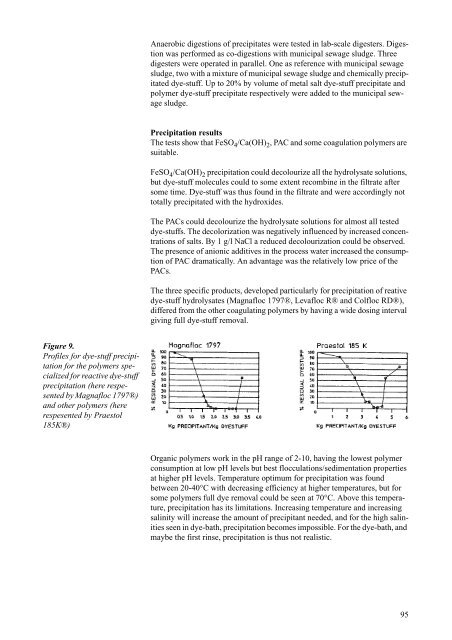

Figure 9.<br />

Profiles for dye-stuff precipitation<br />

for <strong>the</strong> polymers specialized<br />

for reactive dye-stuff<br />

precipitation (here respesented<br />

by Magnafloc 1797®)<br />

and o<strong>the</strong>r polymers (here<br />

respesented by Praes<strong>to</strong>l<br />

185K®)<br />

Anaerobic digestions of precipitates were tested in lab-scale digesters. Digestion<br />

was performed as co-digestions with municipal sewage sludge. Three<br />

digesters were operated in parallel. One as reference with municipal sewage<br />

sludge, two with a mixture of municipal sewage sludge and chemically precipitated<br />

dye-stuff. Up <strong>to</strong> 20% by volume of metal salt dye-stuff precipitate and<br />

polymer dye-stuff precipitate respectively were added <strong>to</strong> <strong>the</strong> municipal sewage<br />

sludge.<br />

Precipitation results<br />

The tests show that FeSO 4/Ca(OH) 2, PAC and some coagulation polymers are<br />

suitable.<br />

FeSO 4/Ca(OH) 2 precipitation could decolourize all <strong>the</strong> hydrolysate solutions,<br />

but dye-stuff molecules could <strong>to</strong> some extent recombine in <strong>the</strong> filtrate after<br />

some time. Dye-stuff was thus found in <strong>the</strong> filtrate and were accordingly not<br />

<strong>to</strong>tally precipitated with <strong>the</strong> hydroxides.<br />

The PACs could decolourize <strong>the</strong> hydrolysate solutions for almost all tested<br />

dye-stuffs. The decolorization was negatively influenced by increased concentrations<br />

of salts. By 1 g/l NaCl a reduced decolourization could be observed.<br />

The presence of anionic additives in <strong>the</strong> process water increased <strong>the</strong> consumption<br />

of PAC dramatically. An advantage was <strong>the</strong> relatively low price of <strong>the</strong><br />

PACs.<br />

The three specific products, developed particularly for precipitation of reative<br />

dye-stuff hydrolysates (Magnafloc 1797®, Levafloc R® and Colfloc RD®),<br />

differed from <strong>the</strong> o<strong>the</strong>r coagulating polymers by having a wide dosing interval<br />

giving full dye-stuff removal.<br />

Organic polymers work in <strong>the</strong> pH range of 2-10, having <strong>the</strong> lowest polymer<br />

consumption at low pH levels but best flocculations/sedimentation properties<br />

at higher pH levels. Temperature optimum for precipitation was found<br />

between 20-40°C with decreasing efficiency at higher temperatures, but for<br />

some polymers full dye removal could be seen at 70°C. Above this temperature,<br />

precipitation has its limitations. Increasing temperature and increasing<br />

salinity will increase <strong>the</strong> amount of precipitant needed, and for <strong>the</strong> high salinities<br />

seen in dye-bath, precipitation becomes impossible. For <strong>the</strong> dye-bath, and<br />

maybe <strong>the</strong> first rinse, precipitation is thus not realistic.<br />

95