Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

hardness in water and extract from textile, spectropho<strong>to</strong>meter scanning for<br />

dye-stuff content in process water, conductivity for salt measuring, and pH.<br />

Quality assesments To assess <strong>the</strong> quality of <strong>the</strong> dyed textiles <strong>the</strong> dye-houses ordinary quality<br />

assessments were used: washing, water, wet rub, and dry rub fastness, evaluated<br />

on a scale from 1 <strong>to</strong> 5 with 5 as <strong>the</strong> best. As always in <strong>the</strong> dye-houses,<br />

colour and shade were assessed by comparing with <strong>the</strong> cus<strong>to</strong>mer samples. The<br />

main part of <strong>the</strong> experiments has been performed on production lots.<br />

Table 4.<br />

Overview of performed<br />

investigations.<br />

Experiments 50 full-scale tests<br />

Recipes 20 different recipes<br />

Dye-stuff colours Brown, red, black, winered, marine, blue,<br />

turquoise, rose, pink, purple, green, mint.<br />

Shades Very light <strong>to</strong> very dark<br />

Recipe variations Temperature<br />

°C<br />

Neutralization<br />

±<br />

Detergents<br />

±<br />

Complexing agents<br />

±<br />

Soft water<br />

°dh<br />

No. of rinses<br />

No.<br />

Quality assessments<br />

Scale<br />

Washing fastness<br />

1-5<br />

Water fastness<br />

1-5<br />

Rub fastness, wet<br />

1-5<br />

Rub fastness, dry<br />

1-5<br />

Colour & shade<br />

Qualitatively<br />

Results and discussion<br />

Quality unafffected None of <strong>the</strong> performed experiments caused quality reductions in <strong>the</strong> finished<br />

lots, nei<strong>the</strong>r when neutralization before hydrolysate rinse were omitted, use of<br />

detergents or complexing auxiliaries were omitted, nor when cold overflow rinse<br />

were replaced by one cold batch rinse followed by a few 95°C hot batch rinses.<br />

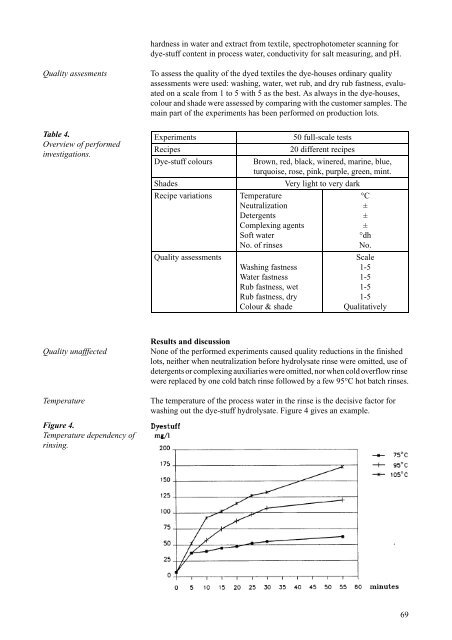

Temperature The temperature of <strong>the</strong> process water in <strong>the</strong> rinse is <strong>the</strong> decisive fac<strong>to</strong>r for<br />

washing out <strong>the</strong> dye-stuff hydrolysate. Figure 4 gives an example.<br />

Figure 4.<br />

Temperature dependency of<br />

rinsing.<br />

69