Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

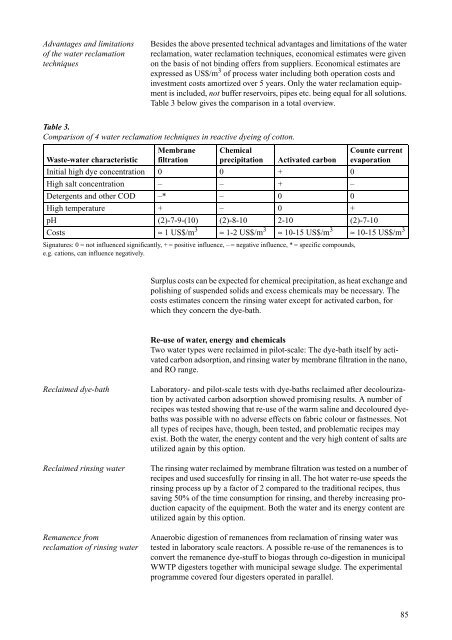

Advantages and limitations<br />

of <strong>the</strong> water reclamation<br />

techniques<br />

Besides <strong>the</strong> above presented technical advantages and limitations of <strong>the</strong> water<br />

reclamation, water reclamation techniques, economical estimates were given<br />

on <strong>the</strong> basis of not binding offers from suppliers. Economical estimates are<br />

expressed as US$/m 3 of process water including both operation costs and<br />

investment costs amortized over 5 years. Only <strong>the</strong> water reclamation equipment<br />

is included, not buffer reservoirs, pipes etc. being equal for all solutions.<br />

Table 3 below gives <strong>the</strong> comparison in a <strong>to</strong>tal overview.<br />

Table 3.<br />

Comparison of 4 water reclamation techniques in reactive dyeing of cot<strong>to</strong>n.<br />

Membrane Chemical<br />

Counte current<br />

Waste-water characteristic filtration precipitation Activated carbon evaporation<br />

Initial high dye concentration 0 0 + 0<br />

High salt concentration – – + –<br />

Detergents and o<strong>the</strong>r COD –* – 0 0<br />

High temperature + – 0 +<br />

pH (2)-7-9-(10) (2)-8-10 2-10 (2)-7-10<br />

Costs ≈ 1 US$/m<br />

Signatures: 0 = not influenced significantly, + = positive influence, – = negative influence, * = specific compounds,<br />

e.g. cations, can influence negatively.<br />

3<br />

≈ 1-2 US$/m 3<br />

≈ 10-15 US$/m 3<br />

≈ 10-15 US$/m 3<br />

Surplus costs can be expected for chemical precipitation, as heat exchange and<br />

polishing of suspended solids and excess chemicals may be necessary. The<br />

costs estimates concern <strong>the</strong> rinsing water except for activated carbon, for<br />

which <strong>the</strong>y concern <strong>the</strong> dye-bath.<br />

Re-use of water, energy and chemicals<br />

Two water types were reclaimed in pilot-scale: The dye-bath itself by activated<br />

carbon adsorption, and rinsing water by membrane filtration in <strong>the</strong> nano,<br />

and RO range.<br />

Reclaimed dye-bath Labora<strong>to</strong>ry- and pilot-scale tests with dye-baths reclaimed after decolourization<br />

by activated carbon adsorption showed promising results. A number of<br />

recipes was tested showing that re-use of <strong>the</strong> warm saline and decoloured dyebaths<br />

was possible with no adverse effects on fabric colour or fastnesses. Not<br />

all types of recipes have, though, been tested, and problematic recipes may<br />

exist. Both <strong>the</strong> water, <strong>the</strong> energy content and <strong>the</strong> very high content of salts are<br />

utilized again by this option.<br />

Reclaimed rinsing water The rinsing water reclaimed by membrane filtration was tested on a number of<br />

recipes and used succesfully for rinsing in all. The hot water re-use speeds <strong>the</strong><br />

rinsing process up by a fac<strong>to</strong>r of 2 compared <strong>to</strong> <strong>the</strong> traditional recipes, thus<br />

saving 50% of <strong>the</strong> time consumption for rinsing, and <strong>the</strong>reby increasing production<br />

capacity of <strong>the</strong> equipment. Both <strong>the</strong> water and its energy content are<br />

utilized again by this option.<br />

Remanence from<br />

reclamation of rinsing water<br />

Anaerobic digestion of remanences from reclamation of rinsing water was<br />

tested in labora<strong>to</strong>ry scale reac<strong>to</strong>rs. A possible re-use of <strong>the</strong> remanences is <strong>to</strong><br />

convert <strong>the</strong> remanence dye-stuff <strong>to</strong> biogas through co-digestion in municipal<br />

WWTP digesters <strong>to</strong>ge<strong>the</strong>r with municipal sewage sludge. The experimental<br />

programme covered four digesters operated in parallel.<br />

85