Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

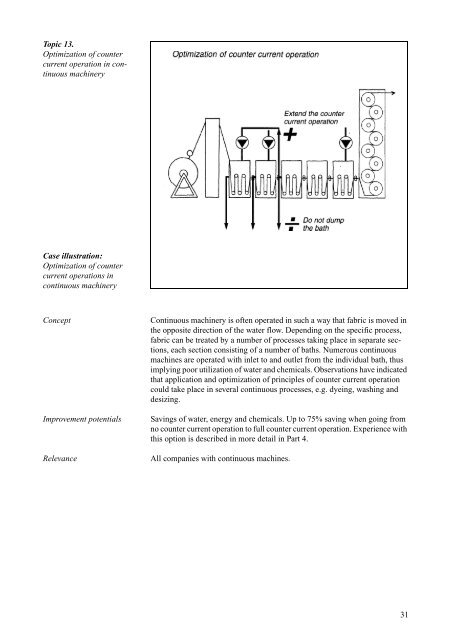

Topic 13.<br />

Optimization of counter<br />

current operation in continuous<br />

machinery<br />

Case illustration:<br />

Optimization of counter<br />

current operations in<br />

continuous machinery<br />

Concept Continuous machinery is often operated in such a way that fabric is moved in<br />

<strong>the</strong> opposite direction of <strong>the</strong> water flow. Depending on <strong>the</strong> specific process,<br />

fabric can be treated by a number of processes taking place in separate sections,<br />

each section consisting of a number of baths. Numerous continuous<br />

machines are operated with inlet <strong>to</strong> and outlet from <strong>the</strong> individual bath, thus<br />

implying poor utilization of water and chemicals. Observations have indicated<br />

that application and optimization of principles of counter current operation<br />

could take place in several continuous processes, e.g. dyeing, washing and<br />

desizing.<br />

Improvement potentials Savings of water, energy and chemicals. Up <strong>to</strong> 75% saving when going from<br />

no counter current operation <strong>to</strong> full counter current operation. Experience with<br />

this option is described in more detail in Part 4.<br />

Relevance All companies with continuous machines.<br />

31