Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

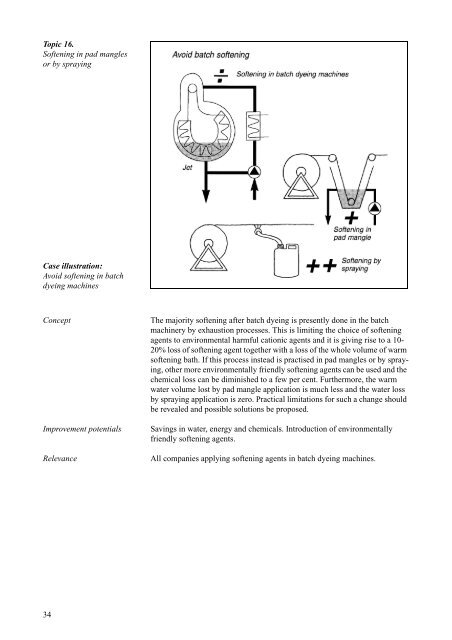

Topic 16.<br />

Softening in pad mangles<br />

or by spraying<br />

Case illustration:<br />

Avoid softening in batch<br />

dyeing machines<br />

Concept The majority softening after batch dyeing is presently done in <strong>the</strong> batch<br />

machinery by exhaustion processes. This is limiting <strong>the</strong> choice of softening<br />

agents <strong>to</strong> environmental harmful cationic agents and it is giving rise <strong>to</strong> a 10-<br />

20% loss of softening agent <strong>to</strong>ge<strong>the</strong>r with a loss of <strong>the</strong> whole volume of warm<br />

softening bath. If this process instead is practised in pad mangles or by spraying,<br />

o<strong>the</strong>r more environmentally friendly softening agents can be used and <strong>the</strong><br />

chemical loss can be diminished <strong>to</strong> a few per cent. Fur<strong>the</strong>rmore, <strong>the</strong> warm<br />

water volume lost by pad mangle application is much less and <strong>the</strong> water loss<br />

by spraying application is zero. Practical limitations for such a change should<br />

be revealed and possible solutions be proposed.<br />

Improvement potentials Savings in water, energy and chemicals. Introduction of environmentally<br />

friendly softening agents.<br />

Relevance All companies applying softening agents in batch dyeing machines.<br />

34