Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

Cleaner Technology Transfer to the Polish Textile ... - Miljøstyrelsen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

The ever increasing demand <strong>to</strong> shade and wash fastness from <strong>the</strong> clothing<br />

industry <strong>to</strong>ge<strong>the</strong>r with demand for prompt and faultless supply of relative<br />

smaller lots in quick shifting shades implies that <strong>the</strong> dye-houses use <strong>the</strong> secure<br />

well-known recipe. The dye-stuff producers deliver a recipe draft with <strong>the</strong><br />

dye-stuff, where <strong>the</strong> use of auxiliaries is recommended.<br />

The use of auxiliaries is general in all recipes and auxiliaries are used in standard<br />

concentrations <strong>to</strong> ensure a safe procedure, although <strong>the</strong> dye-houses are<br />

aware that parts of <strong>the</strong> recipes do not need <strong>the</strong> auxiliaries or only need minor<br />

doses.<br />

Project goals The goal for this research is <strong>to</strong> develop a recipe for <strong>the</strong> rinse in <strong>the</strong> reactive<br />

dyeing of cot<strong>to</strong>n without <strong>the</strong> use of detergents (i.e. surface active agents),<br />

complexing agents or dispersing agents. If possible <strong>to</strong> avoid <strong>the</strong> traditional<br />

neutralization before rinse.<br />

Project strategy The overall strategy of <strong>the</strong> research has been <strong>to</strong> use full-scale dyeings in different<br />

batch dyeing machines. The confidence in labora<strong>to</strong>ry research is very<br />

limited in <strong>the</strong> dye-houses, because of <strong>the</strong> insufficient physical load and <strong>the</strong><br />

unrealistic way <strong>the</strong> rinse water is changed in <strong>the</strong> labora<strong>to</strong>ry containers.<br />

Reactive dyeing of cot<strong>to</strong>n Reactive dyeing of cot<strong>to</strong>n is <strong>the</strong> most common wet treatment of textile processes<br />

world-wide. Today, batch dyeing is dominating and increasing.<br />

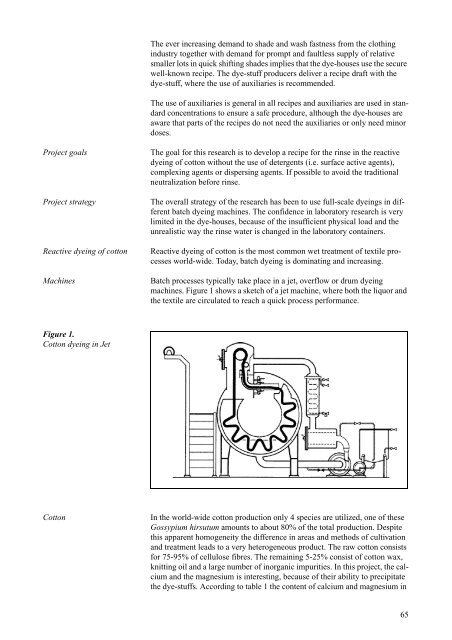

Machines Batch processes typically take place in a jet, overflow or drum dyeing<br />

machines. Figure 1 shows a sketch of a jet machine, where both <strong>the</strong> liquor and<br />

<strong>the</strong> textile are circulated <strong>to</strong> reach a quick process performance.<br />

Figure 1.<br />

Cot<strong>to</strong>n dyeing in Jet<br />

Cot<strong>to</strong>n In <strong>the</strong> world-wide cot<strong>to</strong>n production only 4 species are utilized, one of <strong>the</strong>se<br />

Gossypium hirsutum amounts <strong>to</strong> about 80% of <strong>the</strong> <strong>to</strong>tal production. Despite<br />

this apparent homogeneity <strong>the</strong> difference in areas and methods of cultivation<br />

and treatment leads <strong>to</strong> a very heterogeneous product. The raw cot<strong>to</strong>n consists<br />

for 75-95% of cellulose fibres. The remaining 5-25% consist of cot<strong>to</strong>n wax,<br />

knitting oil and a large number of inorganic impurities. In this project, <strong>the</strong> calcium<br />

and <strong>the</strong> magnesium is interesting, because of <strong>the</strong>ir ability <strong>to</strong> precipitate<br />

<strong>the</strong> dye-stuffs. According <strong>to</strong> table 1 <strong>the</strong> content of calcium and magnesium in<br />

65